Filter press filter plate handle with lubrication, loosening prevention and shaft rotation prevention functions

A filter press filter plate, anti-shaft rotation technology, applied in filtration separation, separation methods, chemical instruments and methods, etc. Increase, ensure work efficiency, good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

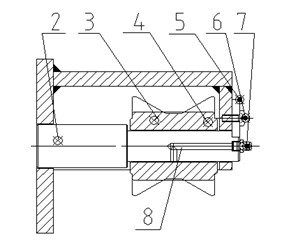

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A filter plate handle for a filter press with lubricating, anti-loosening and anti-rotation functions, which includes a handle-type roller frame 1, a double-wheel groove-type roller frame below the handle-type roller frame 1, a trapezoidal groove-type roller 3 and a cylindrical type The roller 4 is positioned in the roller frame 1 through the roller shaft 2 one front and one back, and the end of the roller shaft 2 has a gap and adopts a pressing plate 5 to position the roller shaft 2 . The diameter of the cylindrical roller 4 is equal to the diameter of the groove bottom of the trapezoidal groove roller 3 . Described roller axle 2 is made of positioning axle and roller axle, and the diameter of positioning axle is greater than the diameter of roller axle. There is an oil guide hole 8 in the center of the front part of the roller shaft, and the outlet of the oil guide hole is located on the axial surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com