Novel solid insulated switch

A solid insulated switch, a new type of technology, applied in the direction of electric switches, switchgear, switchgear settings, etc., can solve the problems of large size, unfavorable miniaturization and development of electrical equipment, and inability to be interchangeable and universal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

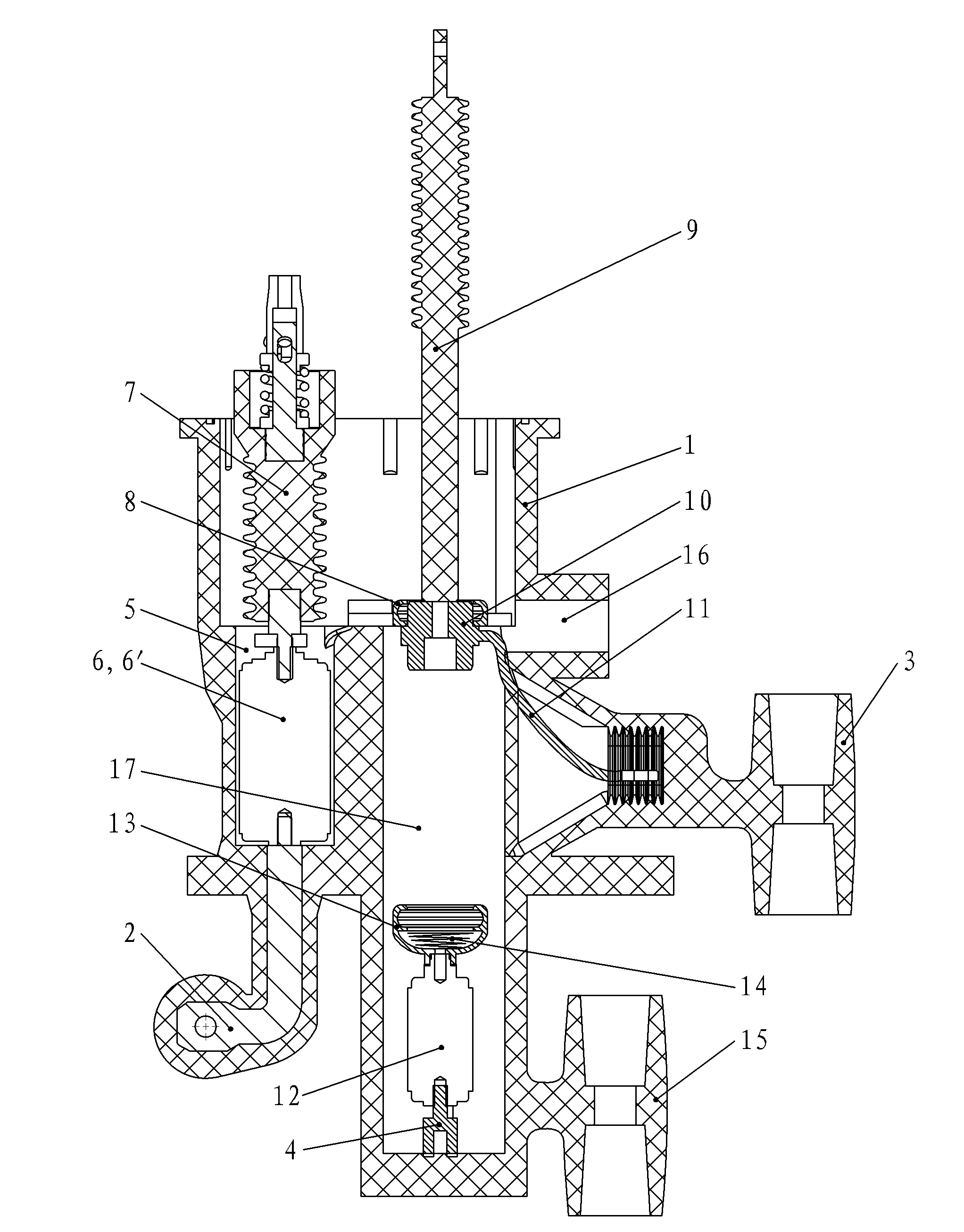

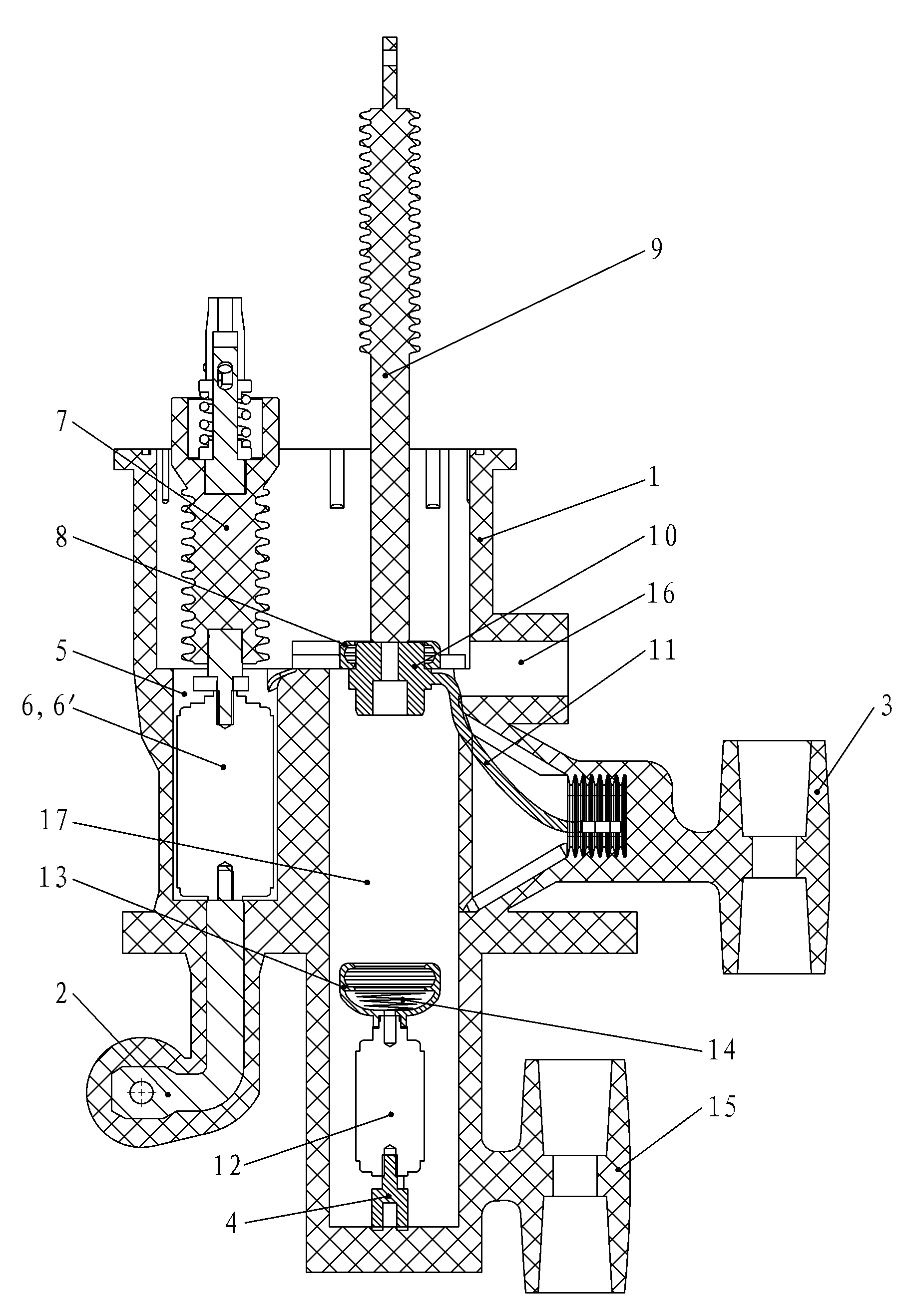

[0011] like figure 1 As shown, the novel solid insulated switch of the present invention includes an insulating shell 1, which is formed integrally with epoxy resin, on which a bus terminal 2, an outlet bushing 3 and a grounding terminal 4 are arranged, and the insulating shell 1 is provided with a first The cavity 5 and the second cavity 17, the first cavity 5 is equipped with a vacuum switch tube 6 for a load switch or a vacuum switch tube 6' for a circuit breaker, the bus terminal 2 and the vacuum switch tube 6 for a load switch or a vacuum switch for a circuit breaker The static contact seat of the switch tube 6' is connected, and a vacuum switch tube control mechanism 7 is arranged above the first cavity 5, and the vacuum switch tube control mechanism 7 is connected to the vacuum switch tube 6 for the load switch or the vacuum switch tube 6' for the circuit breaker. The moving contacts are connected to each other, and are used to control the on-off state of the vacuum swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com