Slide-type vehicle conveying system and slide-type vehicle conveying method

A conveying system and skid-type technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of low cost, high cost, and low conveying efficiency, so as to save space and cost, reduce transportation costs, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

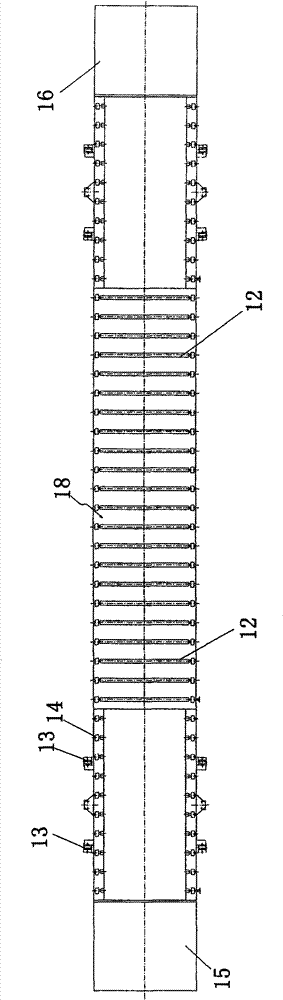

[0058] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

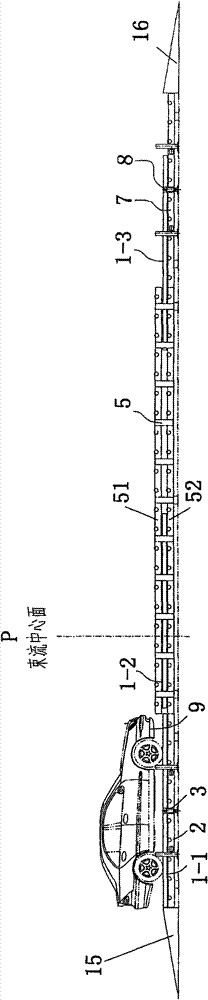

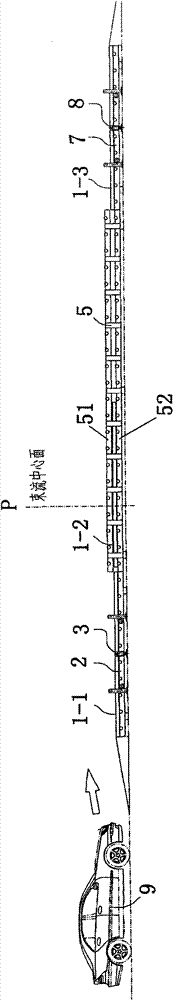

[0059] see figure 1 -3, which shows a skid-type vehicle conveying system, including: an entrance conveying platform 2, including: an entrance vertical lifting device 3, which is set to be able to move in the first horizontal position ( figure 1 horizontal position in ) and the second horizontal position ( Figure 3C vertically move between the horizontal position in the center); the conveying device 18 arranged on the upper end of the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com