Rotational molding mould device and method for manufacturing rotational molding mould

A rotomolding mold and equipment technology, applied in coating and other directions, can solve the problems of reducing the application range of products, unsuitable temperature control, and reducing product quality, etc., to shorten the production cycle, reduce losses, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The equipment of the present invention and the method for producing rotationally molded products will be described in detail below in conjunction with the accompanying drawings.

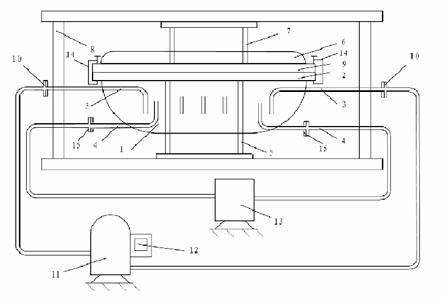

[0023] Such as image 3 As shown, the rotomolding mold of the present invention comprises a mold lower mold 1 and an upper mold 6, and the upper and lower molds respectively have a lower mold flange ring 2 and an upper mold flange ring 9, and the flange ring is provided with mold clamps 14. The upper mold bracket 7 is connected to the support frame 5 through a hinge, so that the upper mold can be opened; the outer surface of the lower mold 1 is covered with a hot oil heating pipeline 3 and a cooling pipeline 4. In order to increase and maintain the strength and shape of the lower mold 1, Lower die is arranged on a support frame 5, upper die 6 is fixed with upper die support 7, and the support frame of lower die is connected on the rotating support 8, and rotating support 8 can provide 360 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com