Soot blower

A technology of equipment and pipelines, which is applied in the direction of lighting and heating equipment, cleaning of non-rotating equipment, cleaning of heat transfer devices, etc., can solve problems such as personal injury, equipment consumption, damage to instruments and boilers, and achieve no hidden dangers of accidents. Reduction, easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

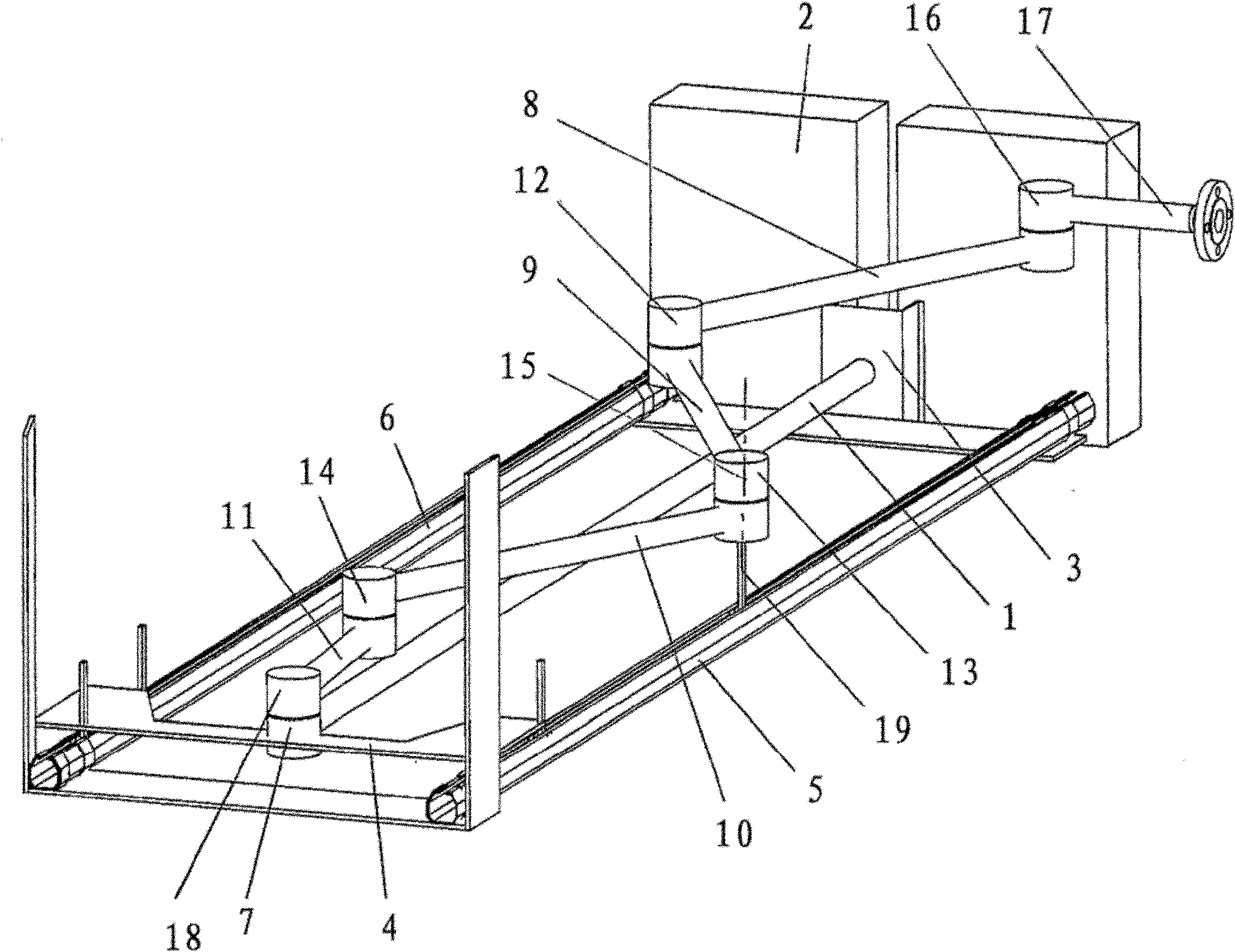

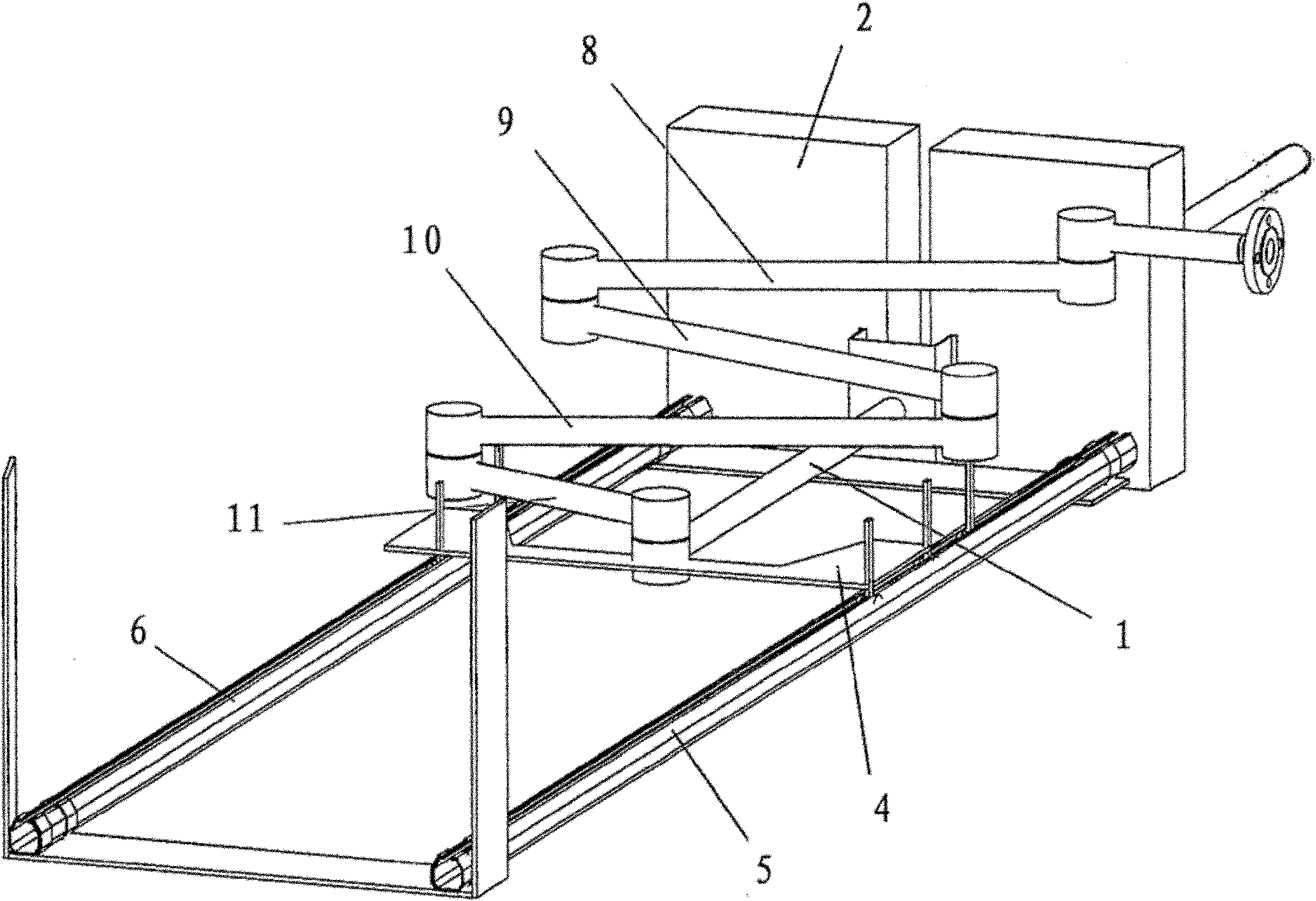

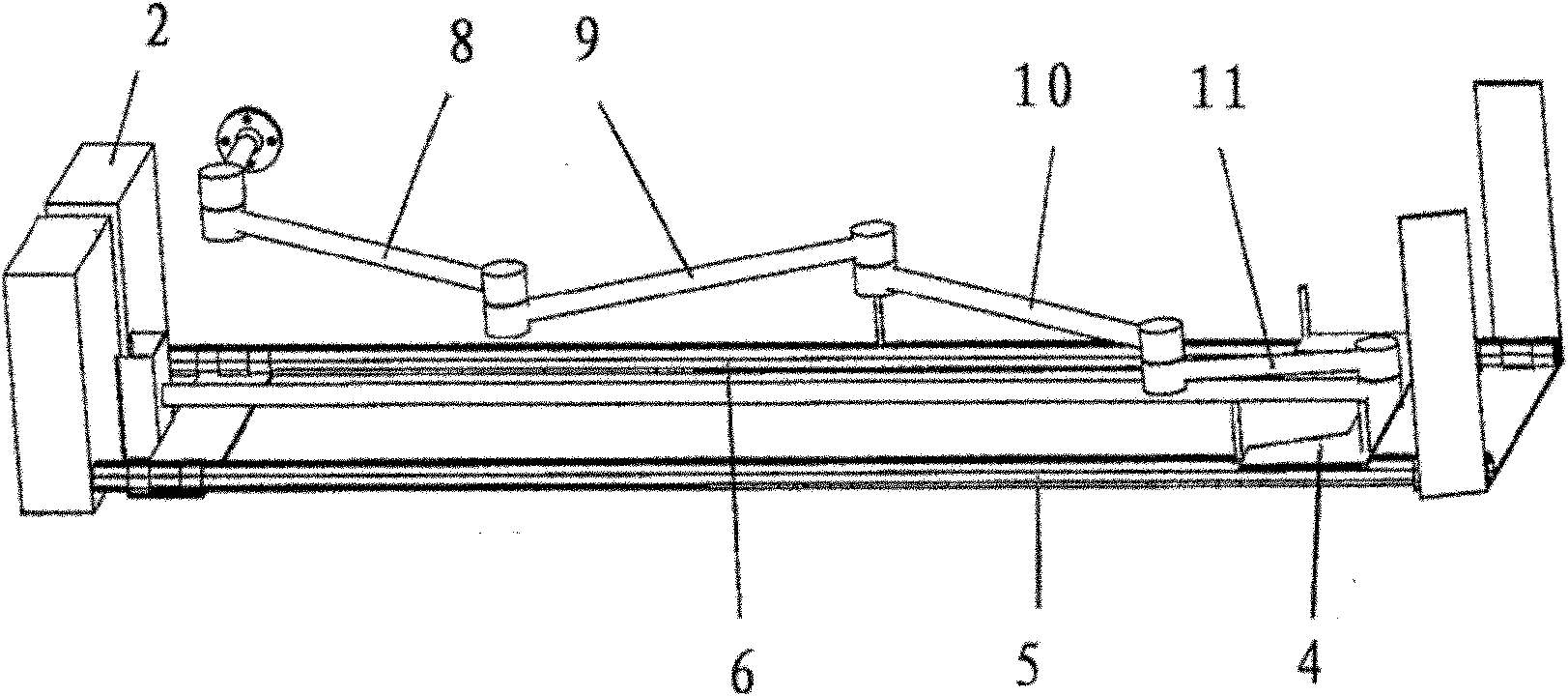

[0020] The sootblower shown in the drawing is used for cleaning the boiler while it is in operation and also for cleaning the heat transfer devices arranged in the boiler. The sootblower shown works with steam having a temperature of up to 420° C. and a pressure of 6 to 21 bar.

[0021] The soot blowing system essentially comprises an axially displaceable blowpipe 1 which can be moved into a schematically shown boiler 2 and out again after the cleaning process. On the boiler side, the lance 1 is guided in a support 3 . At the opposite end on the side facing away from the boiler 2 , the blowpipe 1 is fastened on a drivable, displaceable slide 4 . The blowpipe slide 4 is guided on two guide rails 5 , 6 extending parallel to the blowpipe 1 , with which the outer end 7 of the blowpipe 1 remote from the boiler 2 can be moved in the direction of the boiler 2 and away from it. .

[0022] Steam for cleaning is supplied to the outer end 7 of the blowpipe 1 via a plurality of pipe fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com