Apparatus and method for transferring board-like work

A technology for plate-shaped workpieces and transfer equipment, which is applied in the direction of object destacking, lighting and heating equipment, conveyors, etc., which can solve the problems of difficult glass plate transfer equipment and hinder the high-speed transfer action, and achieve the transfer time and transfer requirements. The effect of reducing the required space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

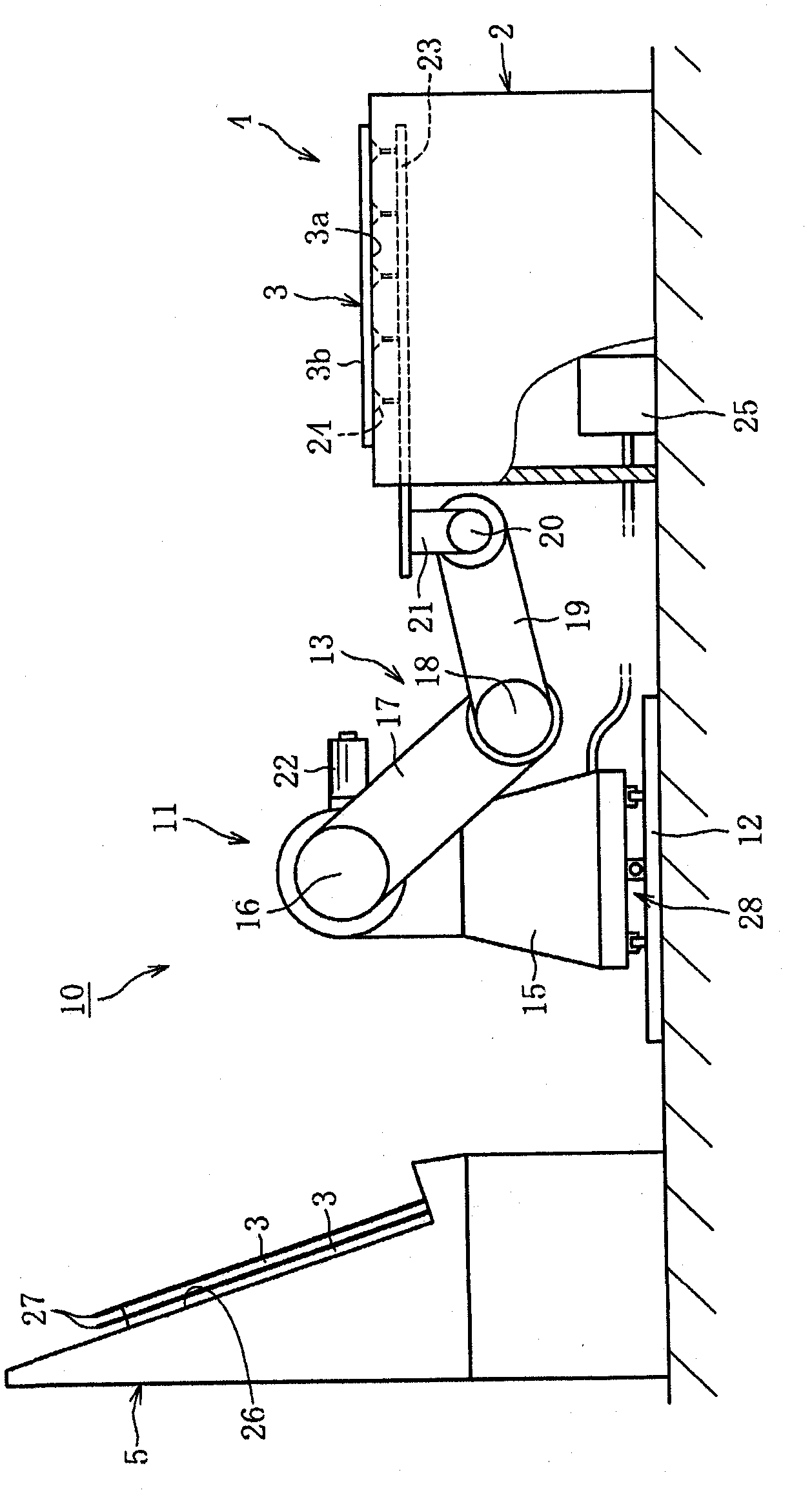

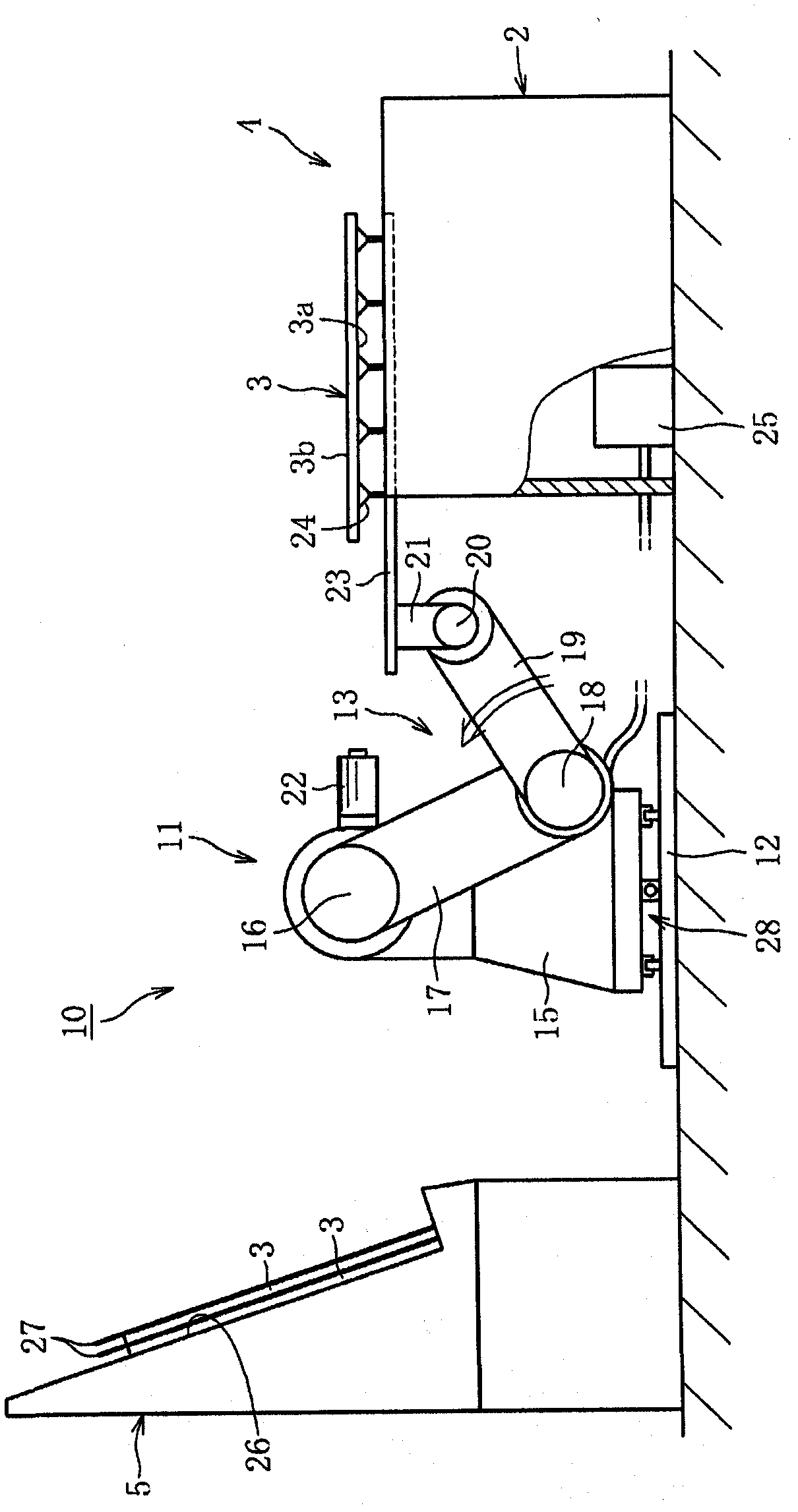

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

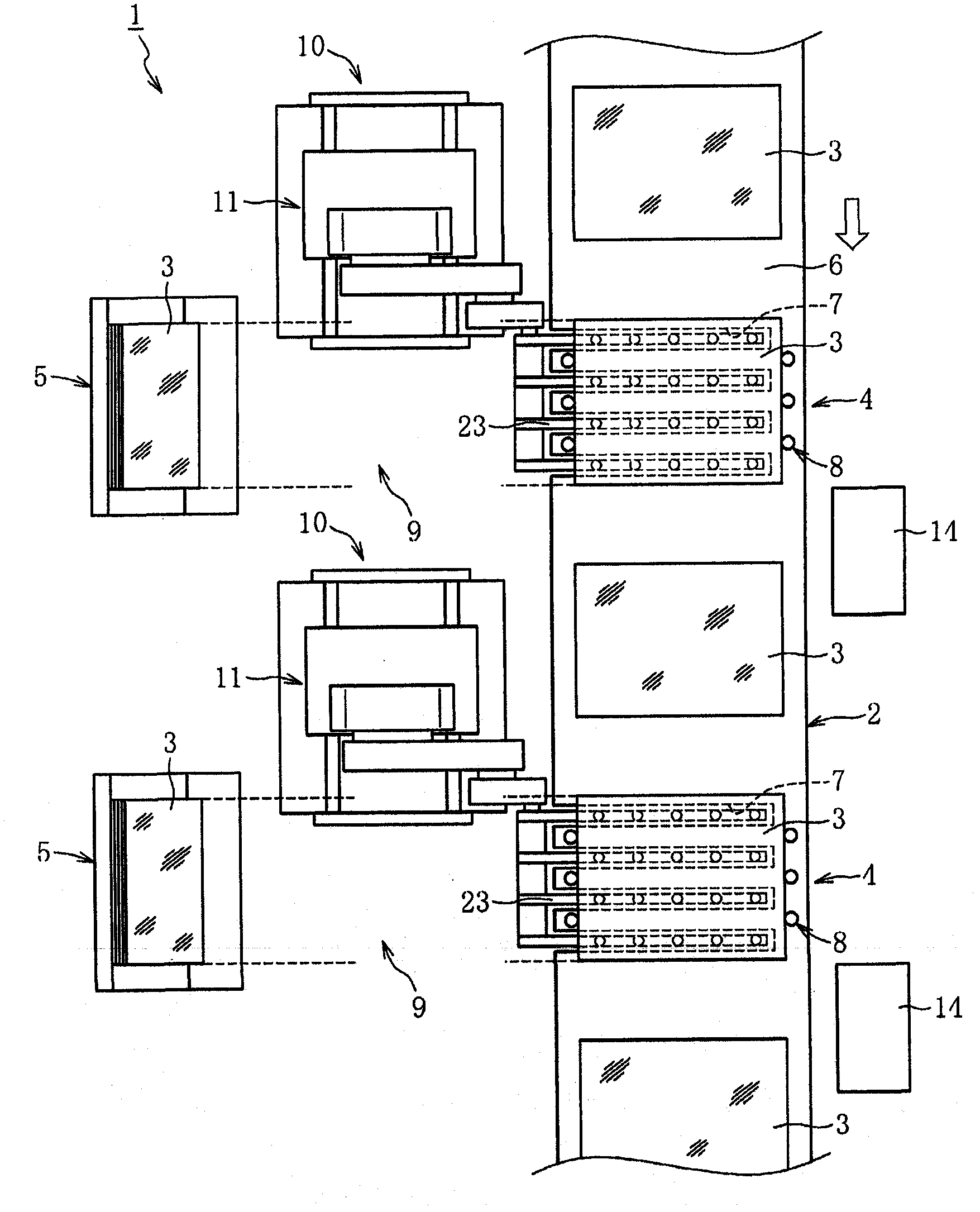

[0046] figure 1 The top view which shows the packaging facility 1 of the glass substrate which concerns on one Embodiment of this invention. The packing equipment 1 involved in this figure is used to obtain the glass substrate 3 for liquid crystal display conveyed by the conveying mechanism 2 to the obtaining position 4 using the conveying device 10 , and stack and place the obtained glass substrate 3 on the conveying mechanism 2 . The device on the packing tray 5 provided on the side of the glass substrate includes a plurality of transfer devices 10, a conveyance mechanism 2, and one or more packing trays 5 for packing the glass substrates 3 in a stacked state.

[0047] In detail, the conveyance mechanism 2 has the conveyance path 6 which can convey the glass substrate 3 in a horizontal posture. The transport path 6 is constituted by an appropriate drive mechanism su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com