Non-multiplying-power straight pull type hoist

A straight-pull hoist technology, applied in the field of non-magnification straight-pull hoist, can solve problems such as unsuitable operation and increased manufacturing costs, and achieve shortened working length, reduced reel diameter and reel length, and energy saving The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

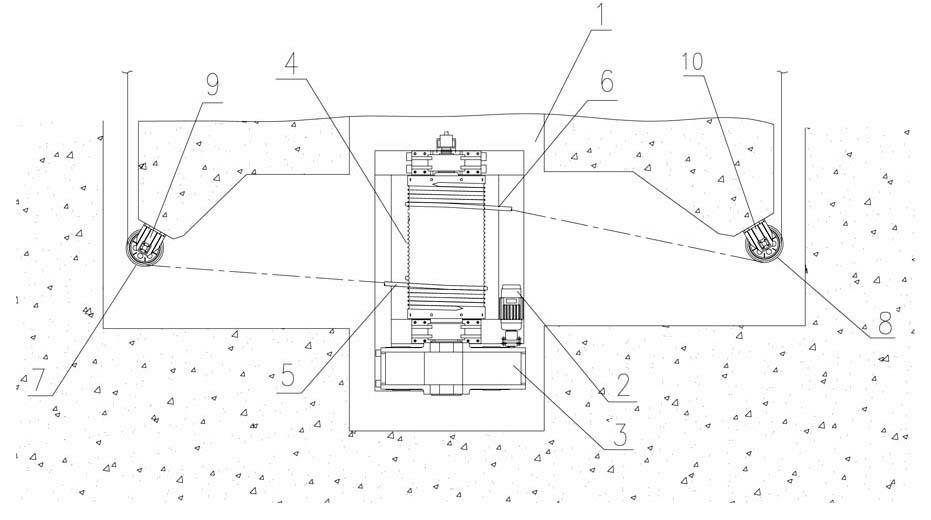

[0008] Such as figure 1 As shown, the non-magnification direct-pull hoist hoist of the present invention includes a hoist hoist body arranged on the base 1, and the hoist body is driven by a motor 2 through a reducer 3 The reel 4 is formed; the left and right sides of the base 1 are respectively symmetrically provided with diverting pulley devices, and the diverting pulley devices are composed of fixed pulleys 7, 8 and pulley seats 9, 10, and the pulley seats 9, 10 and the civil foundation are movable connection structures; steel wire ropes 5 and 6 are fixedly connected to both ends of the reel 4 respectively, and the two steel wire ropes 5 and 6 are wound on the reel 4 in opposite directions, and one is released When the other goes in, the rope groove left by the wire rope is occupied by the wire rope wound in; the other ends of the two wire ropes 5,6 bypass the corresponding fixed pulleys 7,8 and are connected with the rotary gate respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com