Rubber composition for tire tread and tire manufactured with the same

A rubber composition, tire tread technology, applied in special tires, tire parts, rolling resistance optimization, etc., can solve problems such as reduced wear resistance, reduced braking performance, and less reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0083] Production example: Production of rubber composition for tire tread

[0084] (Example and Comparative Example)

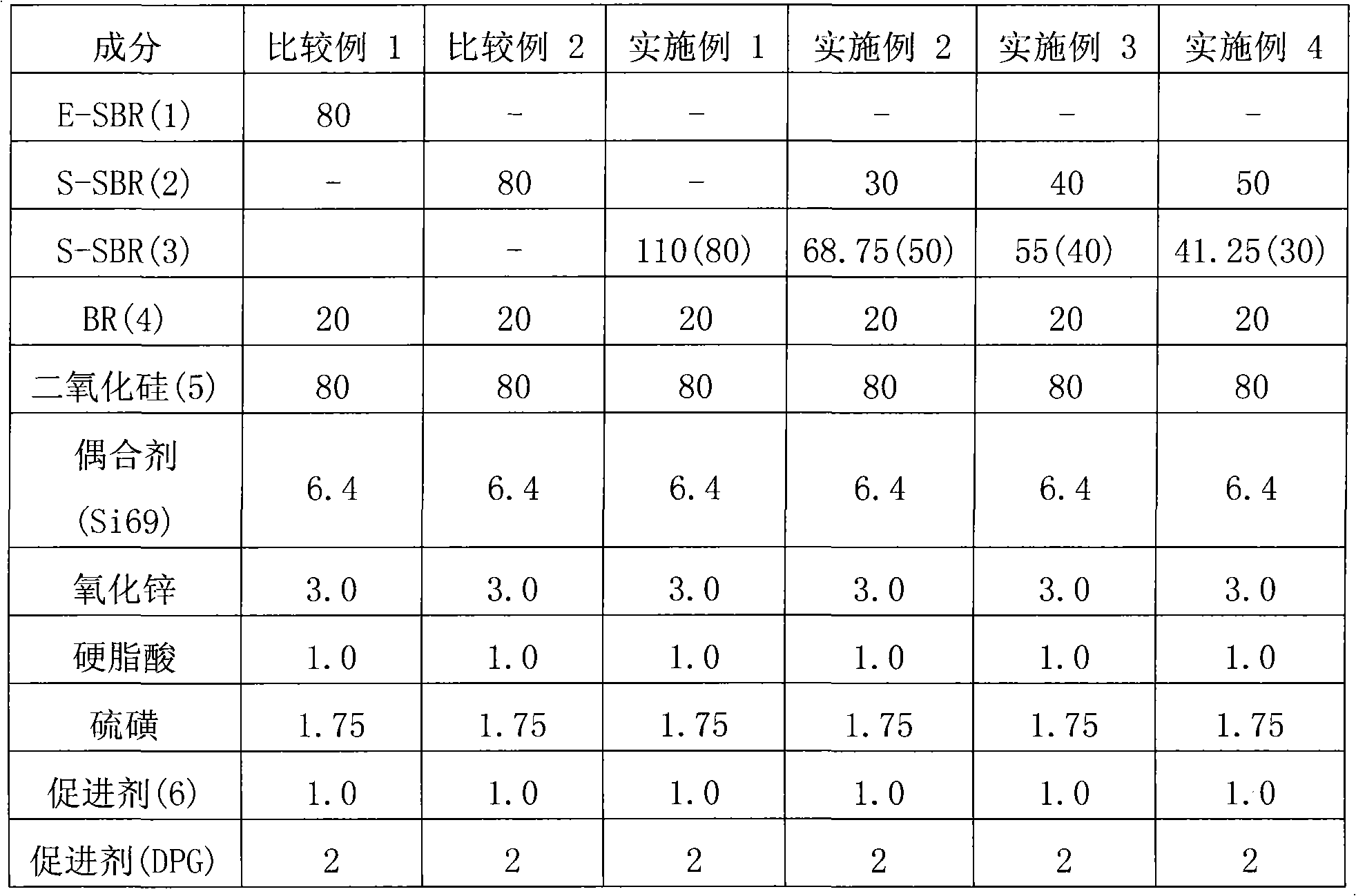

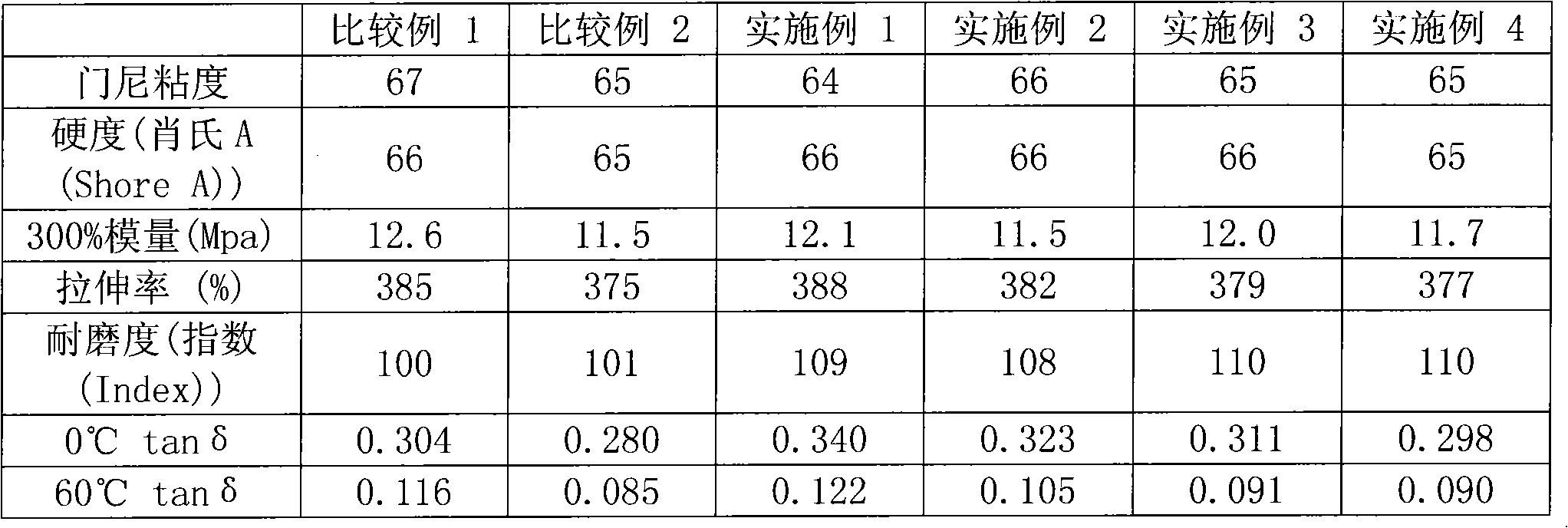

[0085] The rubber compositions for tire treads of Examples 1 to 4 and Comparative Examples 1 and 2 were produced with compositions shown in Table 1 below. The manufacturing method of the rubber composition for tire tread adopts the manufacturing method of tire tread rubber commonly used at present.

[0086] Table 1 (unit: parts by weight)

[0087]

[0088] (1) E-SBR: SBR1502

[0089] (2) S-SBR: The styrene content is 15-25% by weight, the vinyl content contained in butadiene is 60-65% by weight, manufactured by a batch method, and the molecular weight distribution (MWD) is 1.3-1.5. Solution-polymerized styrene-butadiene rubber (SBR) with terminal modification as hydrophilic group (hydroxyl group, -OH) coupled by Sn

[0090] (3) S-SBR: styrene content 30-50% by weight, vinyl content contained in butadiene 20-30% by weight, manufactured by batch method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com