Inspection van for integrating airplane test equipment

A technology for aircraft testing and inspection vehicles, applied in aircraft parts, ground devices, transportation and packaging, etc., can solve problems such as poor mobility, time-consuming and labor-intensive, inability to achieve in-situ testing, and achieve convenient integration and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

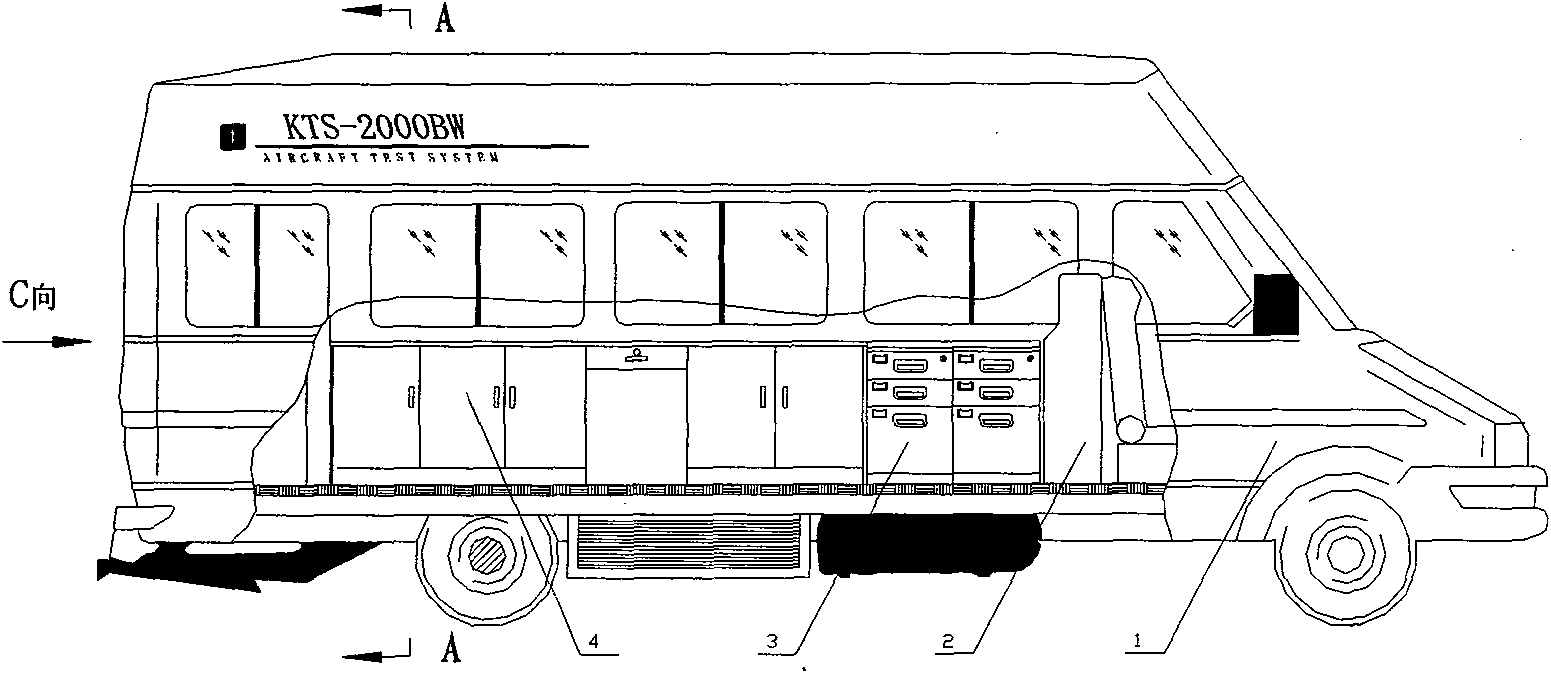

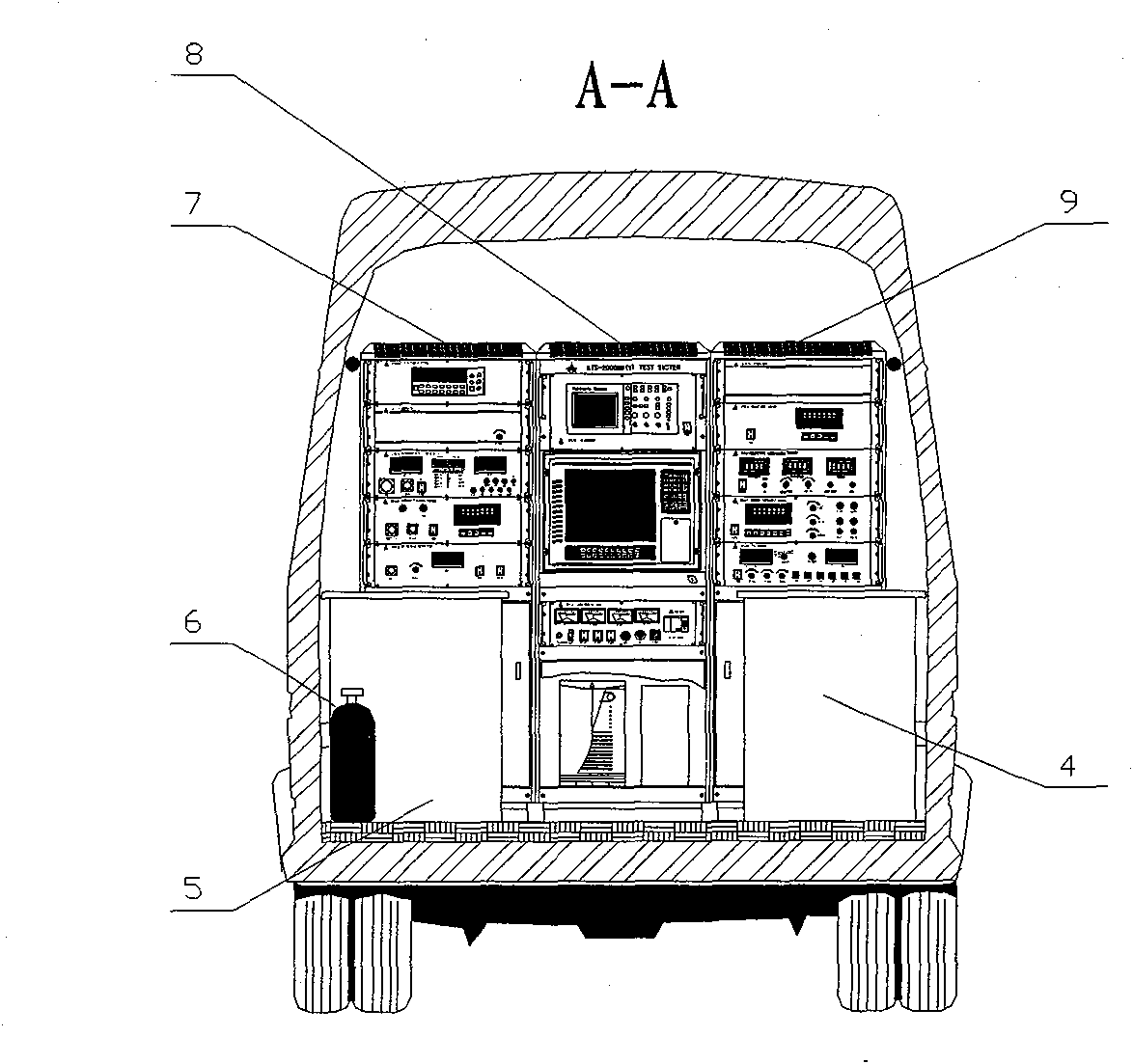

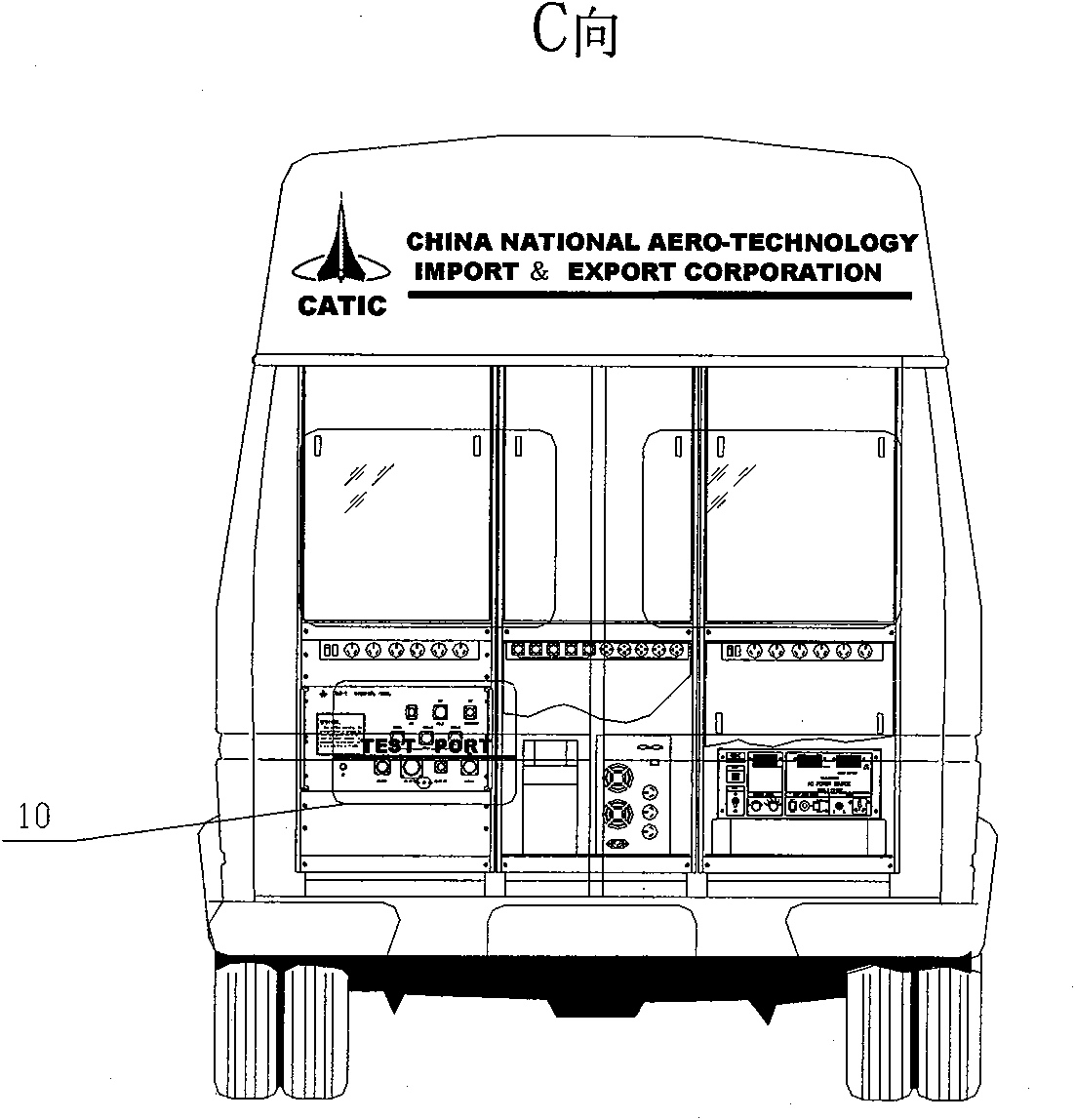

[0022] like figure 1 , figure 2 , image 3 As shown, a testing vehicle used for the integration of aircraft testing equipment, the testing vehicle includes a car body 1, an air conditioner 2, a fire extinguisher 6, and also includes a first-type testing device, a second-type testing device, a testing cable, and a testing port cover 10. Cabinet, workbench, and cable box 3. The first type of detection equipment is installed in the cabinet, the second type of detection equipment is installed in the workbench, and the detection cables are installed in the cable box 3. The detection port cover 10 , the cabinet, the workbench, and the cable box 3 are all installed in the car body 1 .

[0023] Described cabinet comprises left cabinet 7, middle cabinet 8, right cabinet 9, and this left cabinet 7, middle cabinet 8, right cabinet 9 are arranged on the rear portion of car body 1 in a straight line. Described workbench comprises left workbench 5, right workbench 4, and this left workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com