Online detection system of element content of industrial solid powder

A solid powder, element content technology, applied in the direction of measuring devices, instruments, fluorescence/phosphorescence, etc., can solve the problem that the detection method is difficult to meet the rapid real-time online detection of various element content, and achieve the effect of improving production efficiency and compact structure

Inactive Publication Date: 2011-06-15

太原市敏通科技有限公司

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem that the commonly used detection means are difficult to meet the requirements of rapid real-time online detection of the content of various elements in industrial solid powders and the current LIP

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

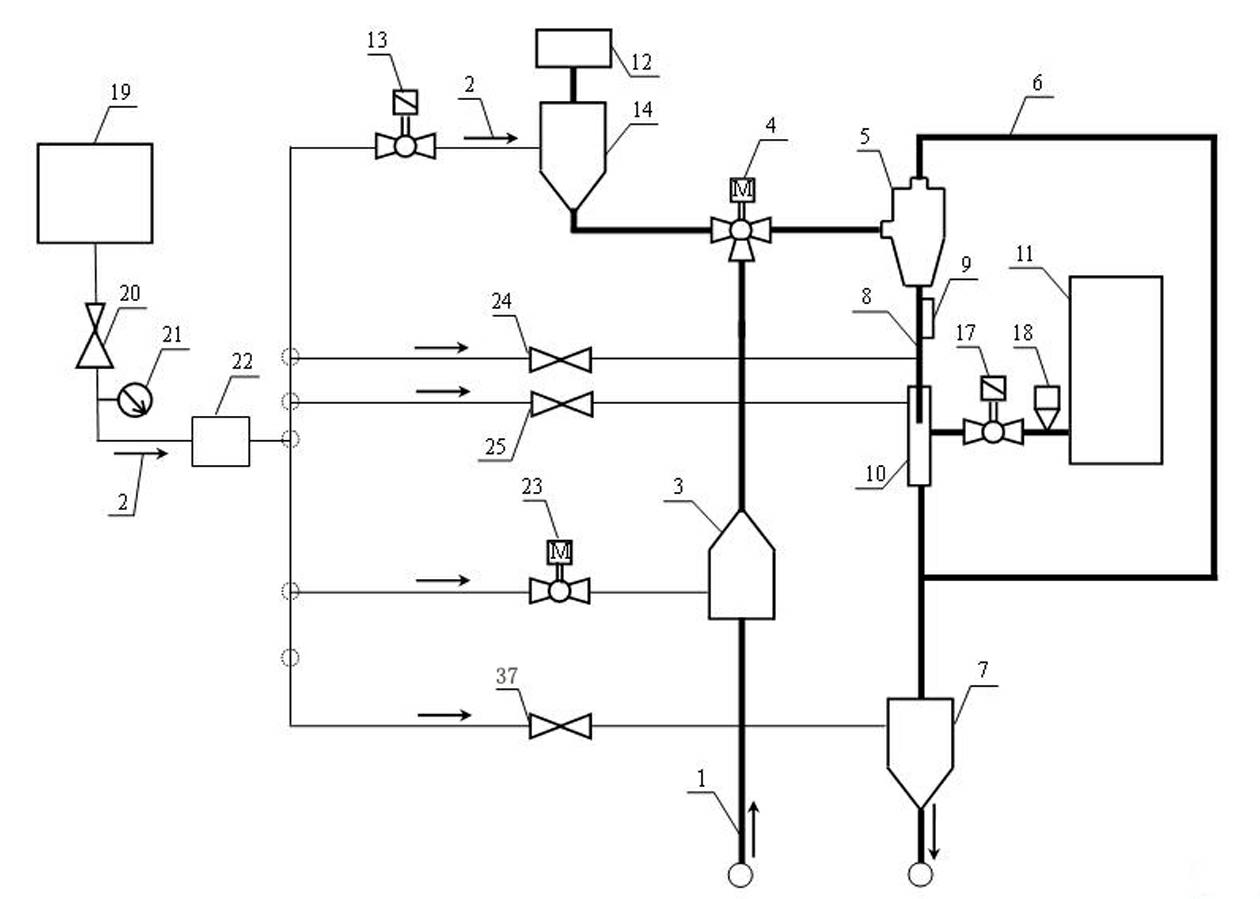

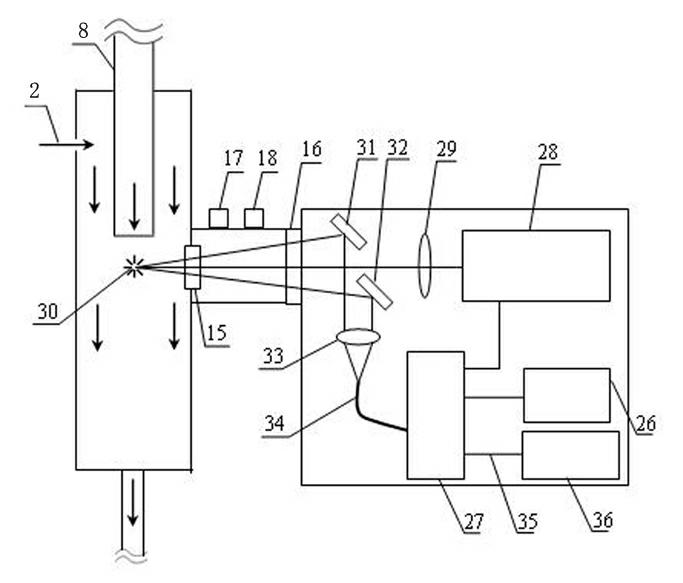

The invention relates to the technical field of industrial automatic measurement, and provides an online detection system of element content of industrial solid powder, aiming at solving the problems that the commonly used detection method cannot meet the requirement on fast and real-time online detection of contents of multiple elements in industrial solid powder, and the LIPS (Laser Induced Plasma Spectroscopy) technology is not applied to online detection of contents of elements in industrial solid powder successfully. The online detection system of element content of industrial solid powder comprises a sampling channel, a measurement room, an LIPS detector, a correction device, a sample discharging channel and a working gas generator for supplying gas for the whole detection system, and realizes application of the LIPS technology in online detection of elements in industrial solid powder by a reasonable and compact structure. Proved by experiments, the detection system provided by the invention can detect multiple elements in the industrial solid powder online rapidly in real time so as to guide workers to adjust the production condition in time to improve the production efficiency.

Description

On-line detection system for industrial solid powder element content technical field The invention relates to the technical field of industrial automatic measurement, in particular to an on-line detection system for element content of industrial solid powder. Background technique At present, chemical analysis, X-ray fluorescence spectrometry and gamma ray analysis are commonly used in the industry for the quantitative analysis of elements in solid powder. However, the process of chemical analysis is complex and time-consuming, which cannot guarantee the timeliness of industrial online control; X-ray fluorescence spectrometry must be equipped with special sample preparation equipment, and the types of detected elements are limited; the disadvantage of gamma-ray analysis is that the detection results are subject to high The fluctuations in the content of atomic number elements (such as iron) have a greater impact, the price of radioactive sources is expensive, and its mainte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/64G01N21/15

Inventor 秦君赵利梅焦庆云

Owner 太原市敏通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com