Intelligent fault diagnosis method for diesel engine

An intelligent diagnosis, diesel engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problem that the determination of other parts of the fault is difficult to accurately determine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

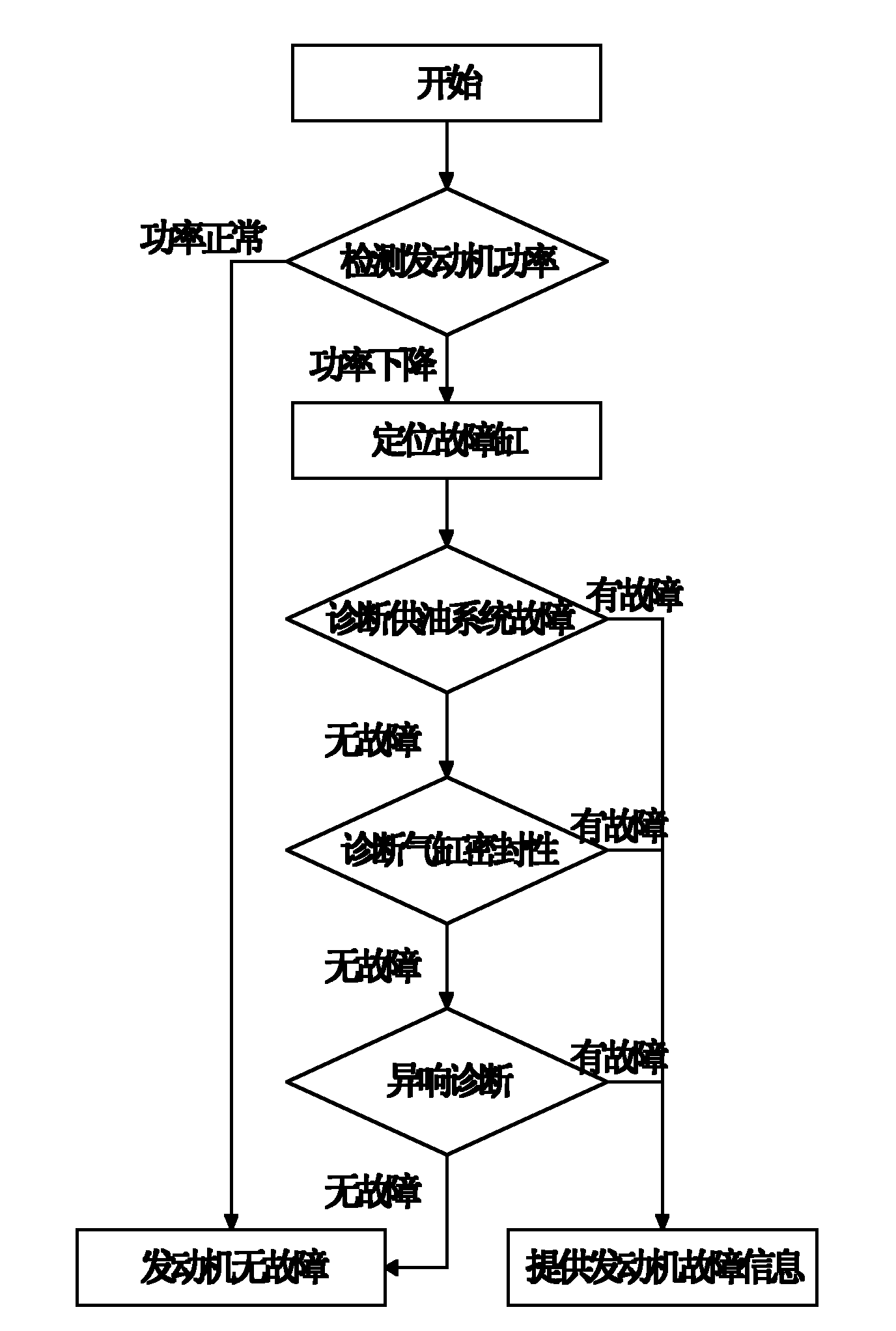

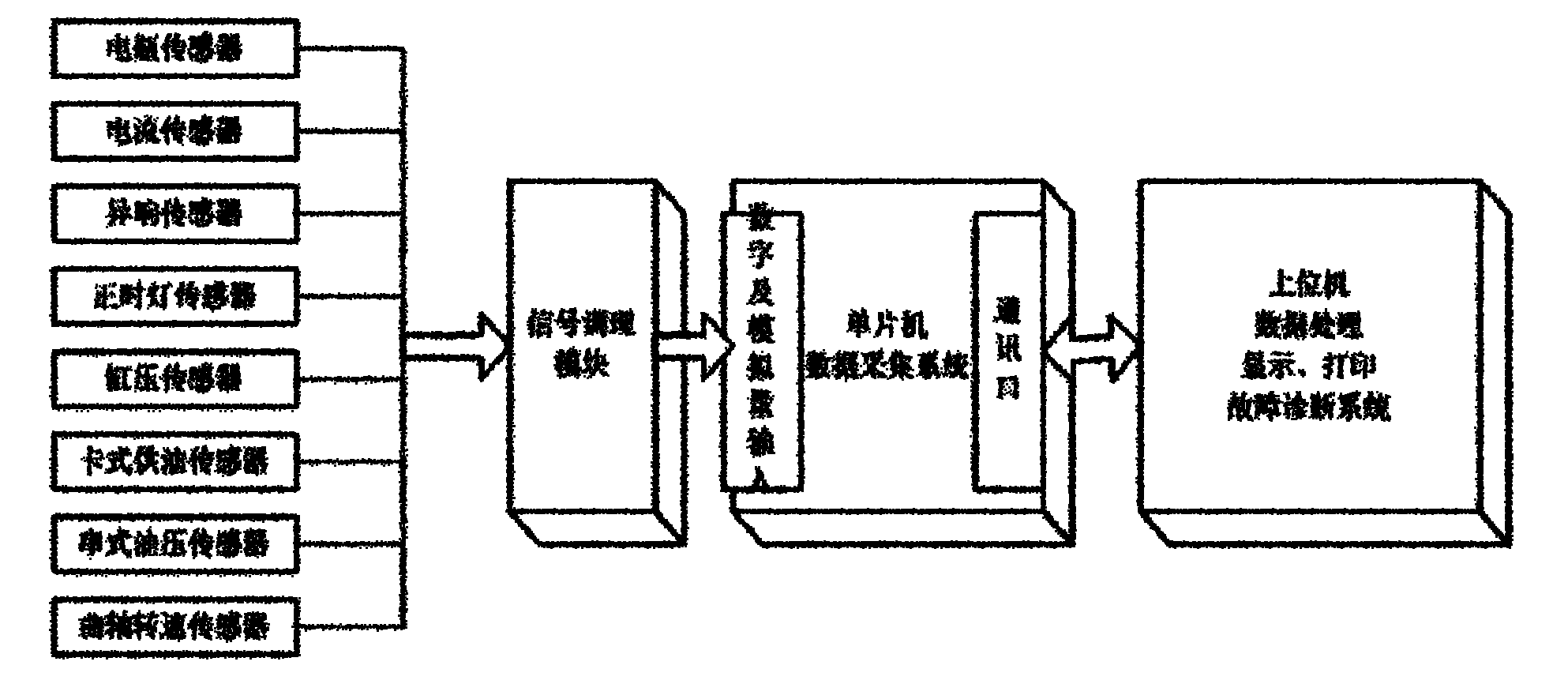

[0038] see figure 1 , a kind of diesel engine fault intelligent diagnosis method of the present invention, comprises the steps:

[0039] 1) Start the diesel engine to be tested. If the diesel engine to be tested cannot start normally, check the no-load battery voltage, battery internal resistance (battery voltage waveform), starting voltage, starting current, starting speed and other signals to judge whether the diesel engine can not be started normally. reason.

[0040] If the diesel engine to be detected can be started, the power of the diesel engine to be detected is judged, and the no-load acceleration time, deceleration time, average power, instantaneous power and torque at the set speed of the engine are detected by the crankshaft speed sensor and the cylinder pressure sensor, and the waiting time is calculated. Detect the power of the diesel engine, if the power drops, it is judged as a faulty diesel engine.

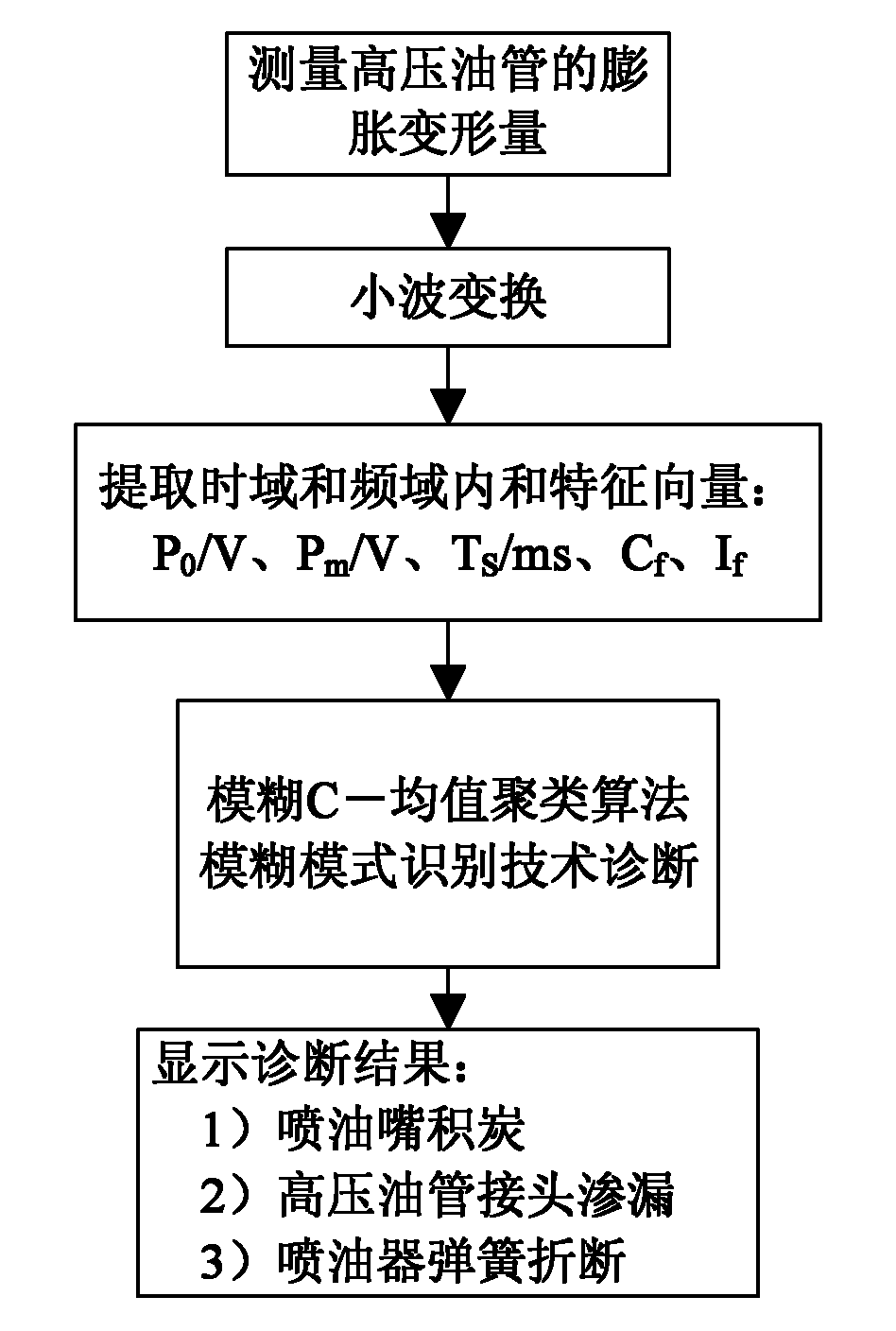

[0041] 2) By measuring the relative cylinder pressure rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com