Electronic detector for pressure of accumulator polar group

A battery and tester technology, which is applied in force/torque/power measuring instruments, instruments, measuring devices, etc., can solve the problems of damaging the plate, affecting the performance of the battery, and easy falling off of positive active materials, so as to avoid swelling and easy falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

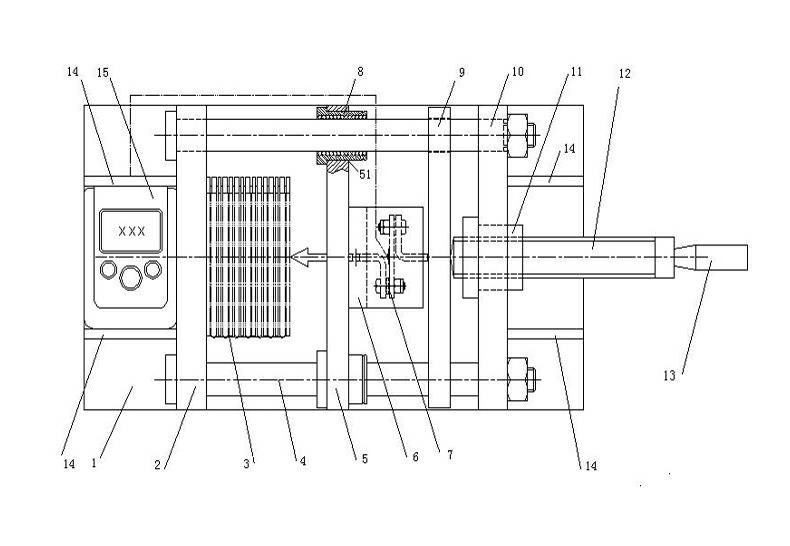

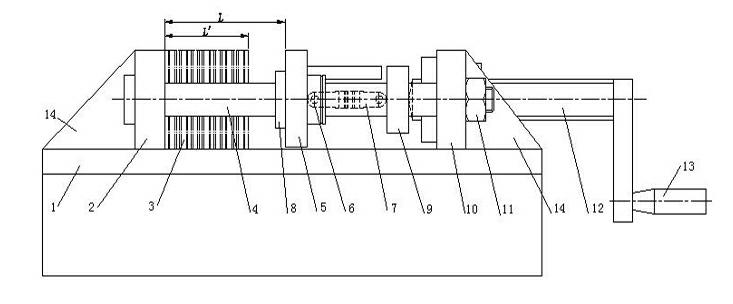

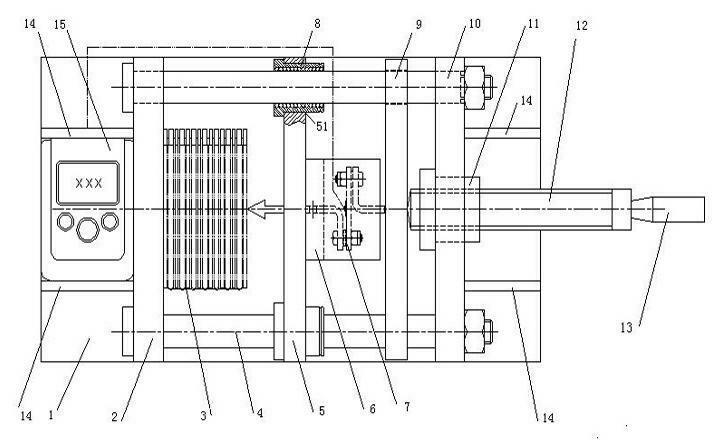

[0013] Such as figure 1 , figure 2 As shown in the figure, an electronic tester for battery pole group pressure, the two ends of the base support plate 1 are provided with a front fixed plate 2 and a rear fixed plate 10 parallel to each other, and a pressure plate is arranged in parallel between the front and rear fixed plates 2 and 10 5, push plate 9, two guide posts 4 are respectively positioned at the both sides of front and rear fixed plate 2,10, and cross the back of pressing plate 5 and push plate 9 and fixedly connect with front and rear fixed plate 2,10. A linear sliding bearing 8 is provided between the guide post 4 and the through hole 51 of the pressure plate 5 , its inner diameter matches the outer circle of the guide post 4 , and its outer diameter matches the inner diameter of the through hole 51 of the press plate 5 . The pressing plate 5 is formed by stacking multi-layer boards, and the thickness can be adjusted by adding or deleting the number of laminates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com