Method for directed induction fracturing grouting in shallow tunnel

A directional induction, shallow buried tunnel technology, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of running grouting, difficult to complete the water plugging reinforcement, uneconomical, etc., saving grouting time and enhancing controllability , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] A directional induced splitting grouting method in a shallow buried tunnel, the induced splitting grouting method comprising the following steps:

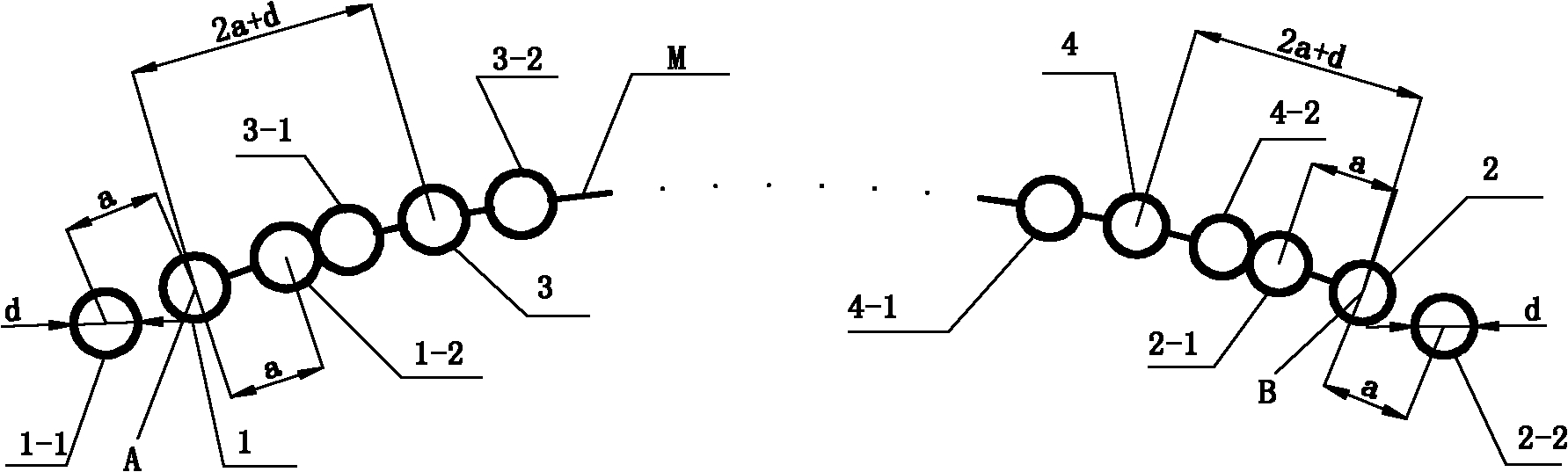

[0024] Step 1, select the grouting contour line AB on the tunnel face, determine the number of grouting holes on the grouting contour line AB N=L / (2a+d)+1, L is the length of the grouting contour line AB, d is the diameter of all grouting holes and all induction holes, a is the distance between the center of the grouting hole and the center of the corresponding induction hole;

[0025] Step 2, taking an end point A of the grouting contour line as the center, drilling the first grouting hole 1, the diameter of the first grouting hole 1 is d;

[0026] Step 3, on the extension line of the grouting contour line AB on the left side of the first grouting hole 1, at a distance from the end point A of the grouting contour line, drill the first induction hole 1-1 with a diameter of d; On the grouting contour line AB on the right sid...

Embodiment approach 2

[0039] Grouting is performed within the range of 88.6° above the tunnel, the grouting contour line is arc-shaped, the radius is 2.5m, the diameter d of the grouting hole and the induction hole is 42mm, the depth of the hole is 10m, and the center of the grouting hole corresponds to The distance a between the centers of the induction holes is 1.5d=63mm.

[0040] A directional induced splitting grouting method in a shallow buried tunnel, the induced splitting grouting method comprising the following steps:

[0041] Step 1: Select the grouting contour line AB on the tunnel face, the length of the grouting contour line AB is L=2.5m×88.6×π / 180=3864mm, and determine the number of grouting holes on the grouting contour line AB= L / (2a+d)+1=3864mm / (2×63mm+42mm)+1=24;

[0042] Step 2, taking an end point A of the grouting contour line as the center, drilling the first grouting hole 1, the diameter of the first grouting hole 1 is 42mm;

[0043]Step 3, on the extension line of the grout...

Embodiment approach 3

[0056] Grouting within 120° above the tunnel, the grouting contour line is arc-shaped, the radius is 4.76m, the diameter d of the grouting hole and the induction hole are both 80mm, and the depth of the hole is 12m, and the center of the grouting hole corresponds to it The distance a between the centers of the induced holes is 2d=160mm.

[0057] A directional induced splitting grouting method in a shallow buried tunnel, the induced splitting grouting method comprising the following steps:

[0058] Step 1: Select the grouting contour line AB on the tunnel face, the length of the grouting contour line AB is L=2.5m×120×π / 180=10000mm, and determine the number of grouting holes on the grouting contour line AB= L / (2a+d)+1=10000mm / (2×160mm+80mm)+1=26;

[0059] Step 2, taking an end point A of the grouting contour line as the center, drilling the first grouting hole 1, the diameter of the first grouting hole 1 is 80mm;

[0060] Step 3, on the extension line of the grouting contour l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com