Flow guiding riffle

A technology of two dividers and deflectors, which is applied in the field of two dividers, can solve the problems of inability to achieve uniform material distribution, uneven material distribution, and difficult to clean, and achieves easy cleaning, enhanced shrinkage effect, and improved shrinkage accuracy. Effect

Inactive Publication Date: 2011-06-15

CHANGSHA KAIYUAN INSTR

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

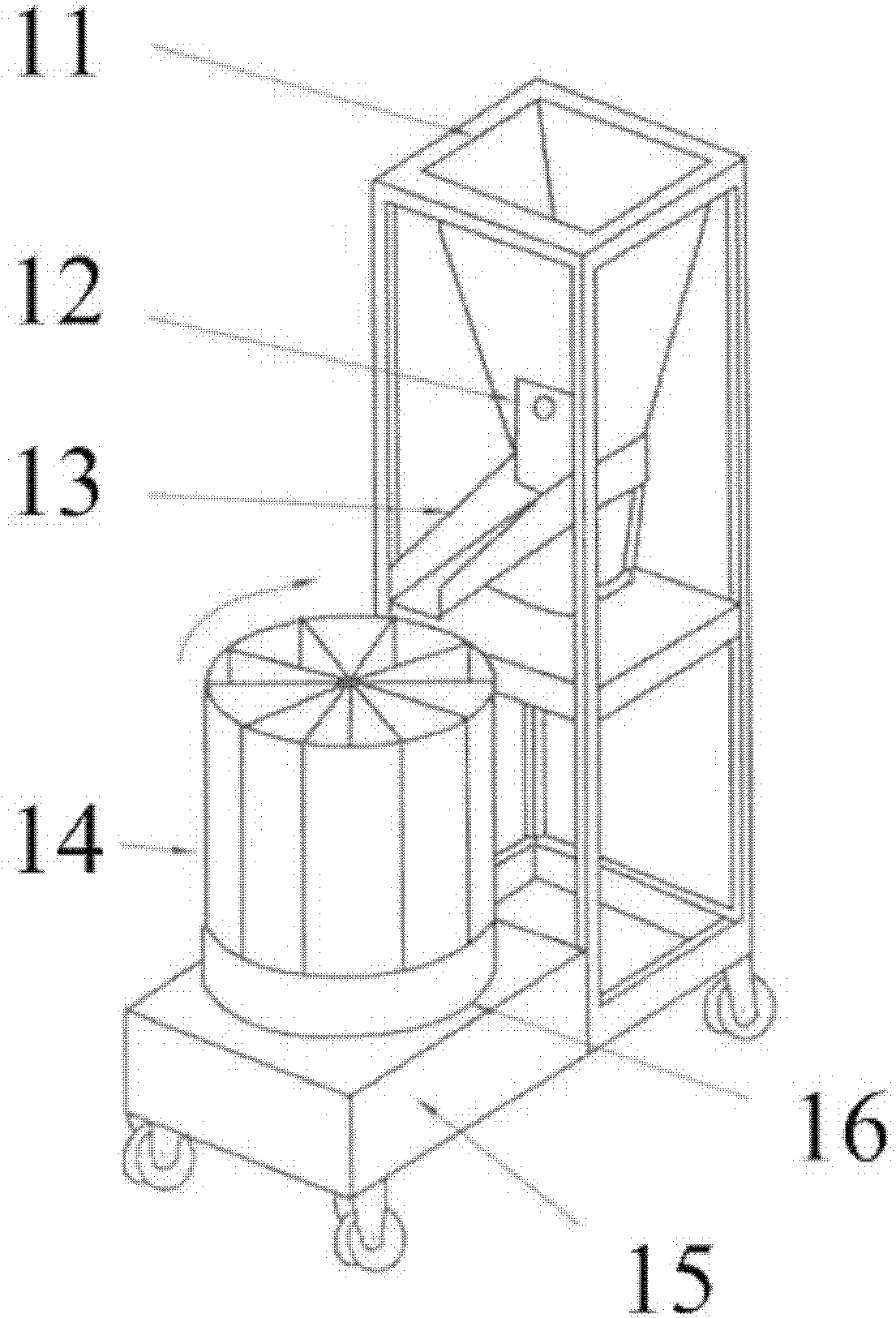

In the process of sliding the sample into the rotary material catcher 14, it is easy to have uneven material distribution

Whether the existing shrinkage device can shrink the sample evenly depends on the uniformity of the sample flow. If the staff loads the sample flow into the feed hopper 11 at an uneven speed, the sample flow will enter the rotary feeder. The amount of each fan-shaped container of 14 is also different, so it is impossible to achieve the effect of uniform material distribution; and, after use, since the rotary feeder 14 is composed of a plurality of fan-shaped containers, it is very difficult to clean up. If it is not cleaned properly, it will affect the next use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

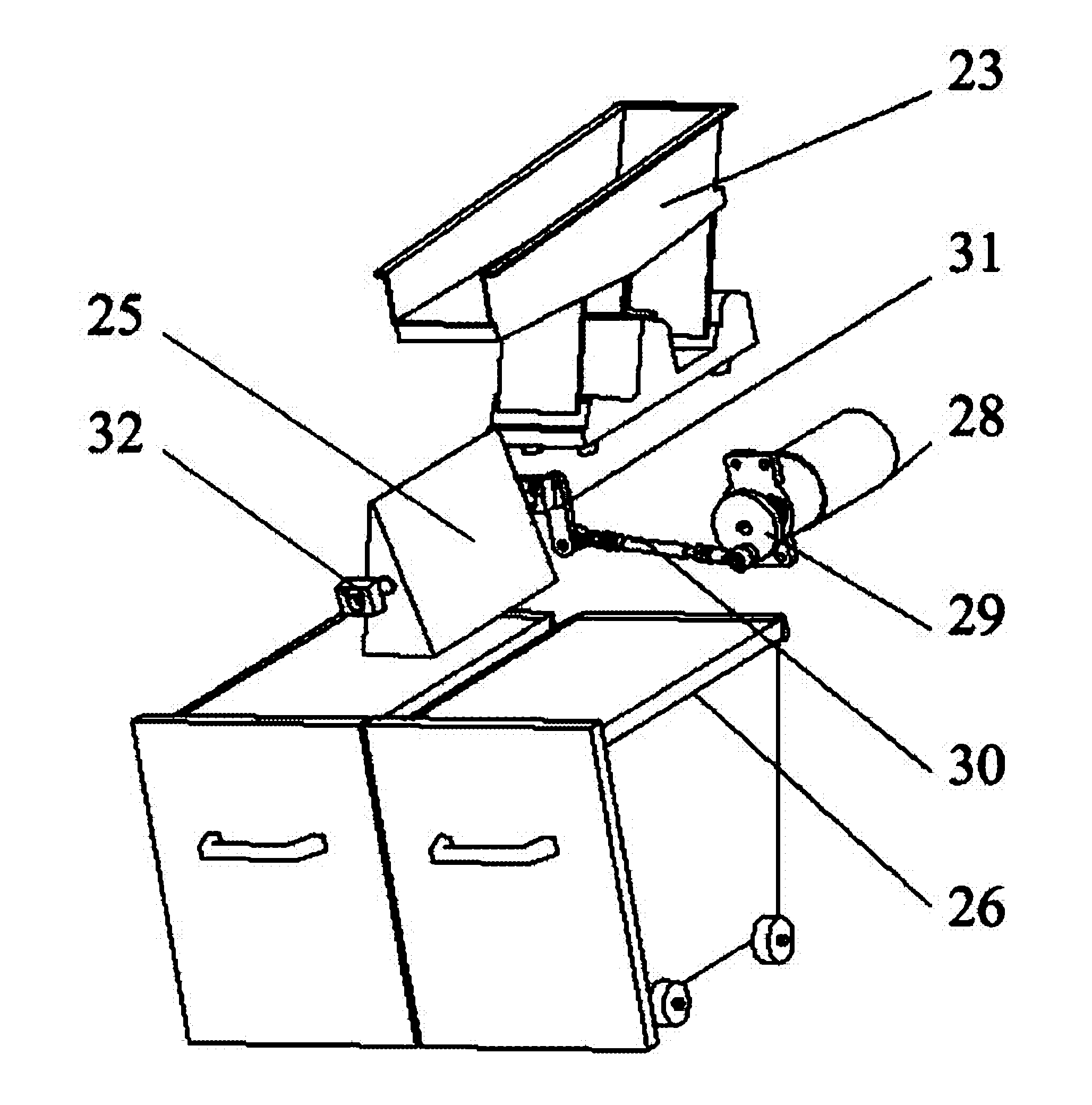

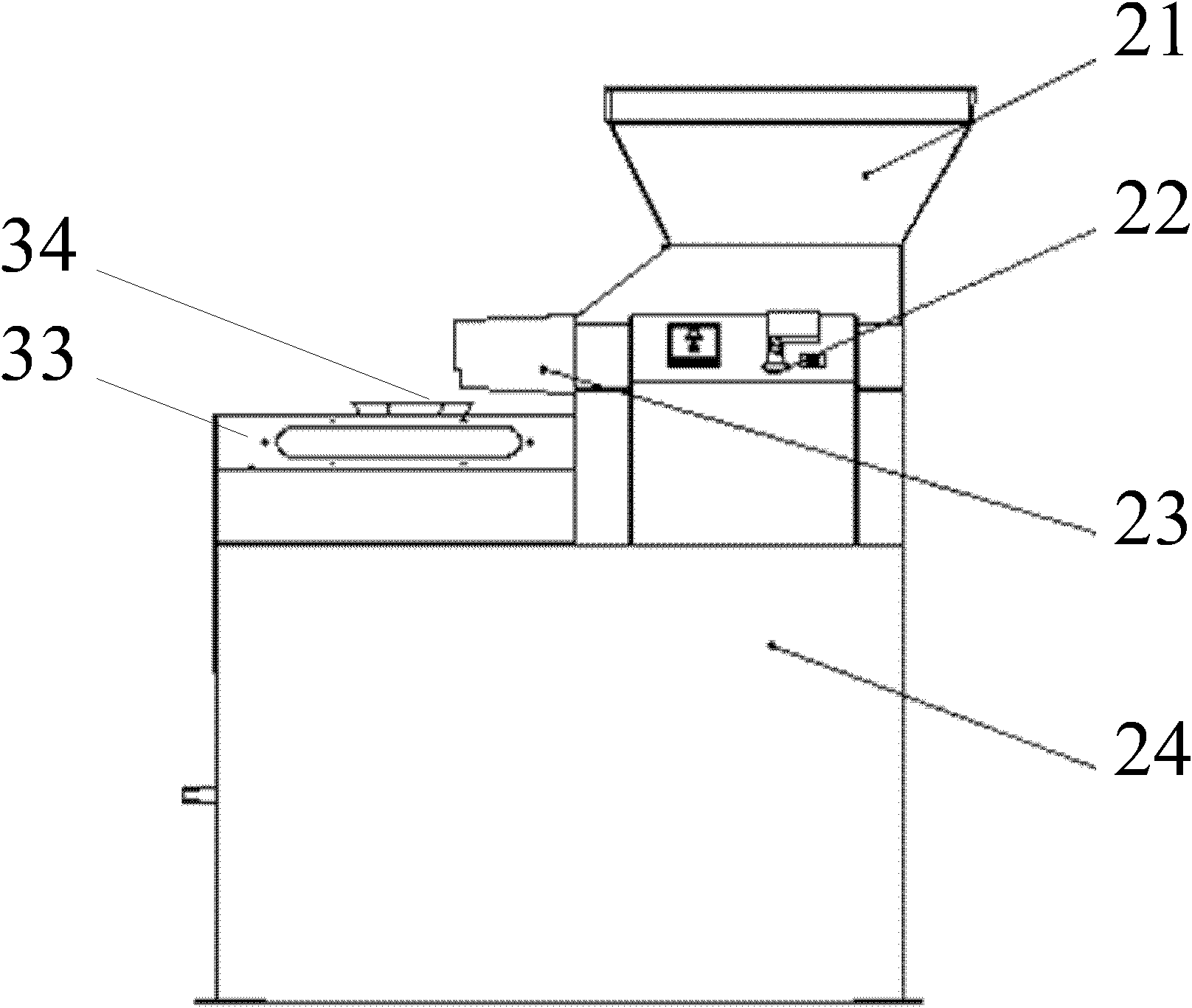

The invention discloses a flow guiding riffle, comprising: a frame; a feeding hopper mounted on the top of the frame; a uniform feeder arranged at the lower part of the outlet of the feeding hopper and on the frame; a flow guiding plate arranged below the outlet of the uniform feeder; a rotating shaft arranged inside the flow guiding plate, wherein one end of the rotating shaft is connected with a power device through a transmission device; receiving hoppers arranged at two sides of the lower part of the flow guide plate; and a control system arranged at the outside of the the frame. By adopting the uniform feeder and the flow guide plate, the flow guiding riffle can uniformly divide a fed sample into two parts which then fall into the receiving hopper, thus the flow guiding riffle raises the division precision and strengthens the division effect, furthermore, the receiving hopper can be cleaned more easily since the receiving hopper is not required to be configured as a rotary receiver consisting of a plurality of sector containers.

Description

A diversion type splitter technical field The invention relates to the field of splitters, more specifically, to a flow-guiding splitter. Background technique The shrinking device is designed according to the provisions of the national standard GB474 "Preparation Method of Coal Samples", and is an indispensable tool for shrinking coal samples. Its main features are reasonable structure, easy to use, suitable for shrinkage sampling of coal, ore samples or other inhomogeneous granular materials. Please refer to Figure 1, which is a schematic diagram of an existing shrinking device, which includes a feed hopper 11, a discharge door 12, a discharge chute 13, a rotary material receiver 14, and a motor 15 And the turntable 16, wherein, the sample enters from the feed hopper 11, passes through the discharge door 12, and slides into the rotary material receiver 14 from the discharge chute 13, and the sample is divided by a plurality of fan-shaped containers of the rotary materia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G47/46

Inventor 罗建文文胜邬茂

Owner CHANGSHA KAIYUAN INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com