Automatic balanced support mechanism for uneven ground support

A ground support and automatic balancing technology, which is applied to the lifting and manipulation of vehicle accessories, vehicle maintenance, transportation and packaging, etc., can solve problems that affect construction efficiency, safety hazards, slow walking speed, etc.

Inactive Publication Date: 2011-06-15

HUNAN WUXIN MACHINERY

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, some domestic construction machinery does not have an independent balance support mechanism. When moving, the balance support only relies on a simple mobile device, which requires strict road conditions and cannot adapt to uneven construction work surfaces. This not only slows down the walking speed, but also affects construction efficiency. At the same time, there are great security risks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

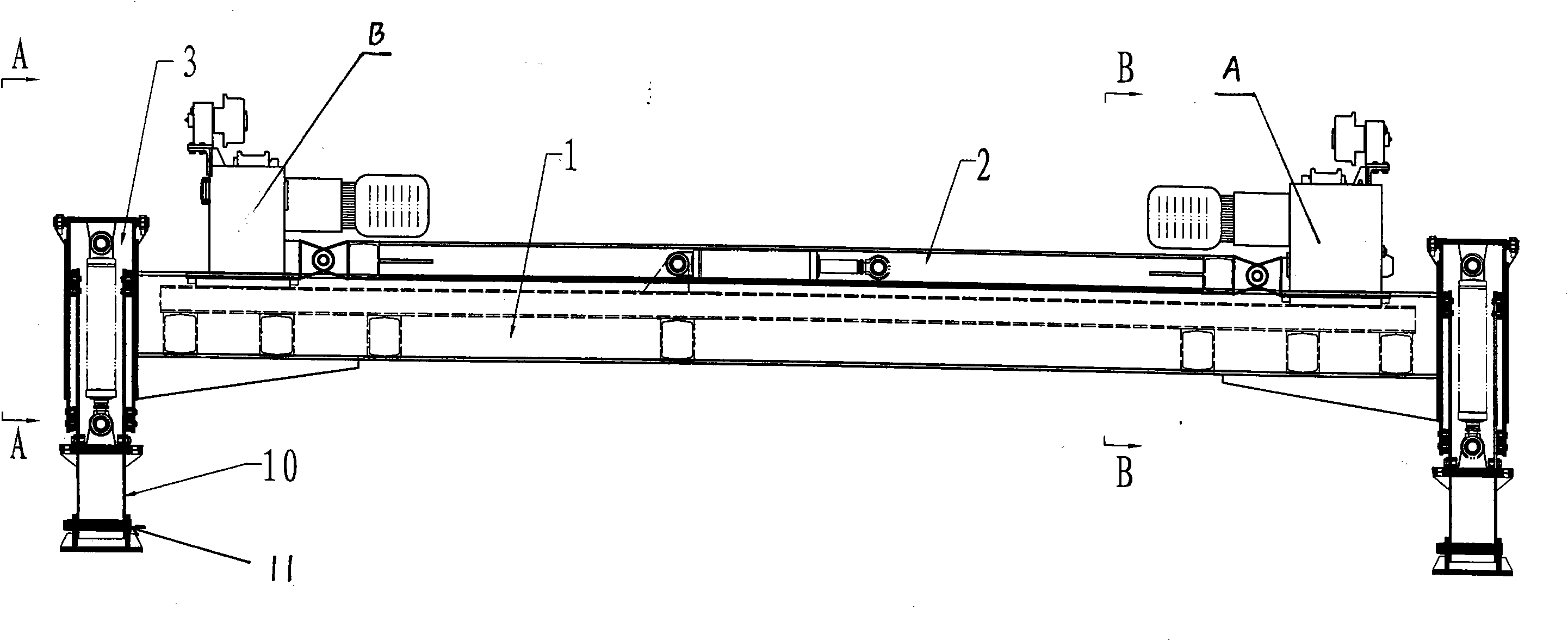

The invention discloses an automatic balanced support mechanism for uneven ground support, which comprises a running frame and two longitudinal traveling wheel sets, wherein the two longitudinal traveling wheel sets are installed on the running frame, and the inside of each longitudinal traveling wheel set is provided with a reverse rail wheel and a hanging roller; the reverse rail wheel is connected with a motor, and connected with the hanging roller by a transmission mechanism; one of the two longitudinal traveling wheel sets comprises an inner box and an outer seat, the reverse rail wheel and the hanging roller are installed in an inner seat, the inner box is connected with the outer seat by positioning pins, and the balancing function of the automatic balanced support mechanism is realized through relative swinging. The automatic balanced support mechanism disclosed by the invention not only ensures the automatic step motion of the engineering machinery, but also realizes the support and balancing of the engineering machinery when the engineering machinery is moved, therefore, the safety performance of the automatic balanced support mechanism is better; and meanwhile, the automatic balanced support mechanism is suitable for any uneven road surface, thereby reducing a great deal of preliminary works of the engineering machinery such as road surface leveling and the like performed before traveling, improving the construction efficiency, and shortening the construction period.

Description

An automatic balancing support mechanism for support on uneven ground technical field The invention relates to engineering operation equipment, in particular to balance support equipment for construction machinery during movement, which can be used for automatic balance support on uneven ground and trestle bridges and other equipment. Background technique According to my country's medium and long-term railway development plan, the railway network should further expand its scale, improve its structure, improve its quality, rapidly expand its transportation capacity, and rapidly improve its equipment level. By 2020, the national railway operating mileage will reach more than 120,000 kilometers, forming a railway network that runs from east to west and from north to south. With the further increase of railway construction, the requirements for construction efficiency are getting higher and higher. At the same time, the safety requirements of construction machinery during cons...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60S9/14

Inventor 王祥军郑怀臣王亚波程波

Owner HUNAN WUXIN MACHINERY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com