Method for manufacturing hand tool handle, and a hand tool handle

A technology for hand tools and handles, which is applied in the field of manufacturing hand tool handles. It can solve problems such as quality changes and unpredictable deformations, and achieve the effect of easy parts transfer and reduced quality changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

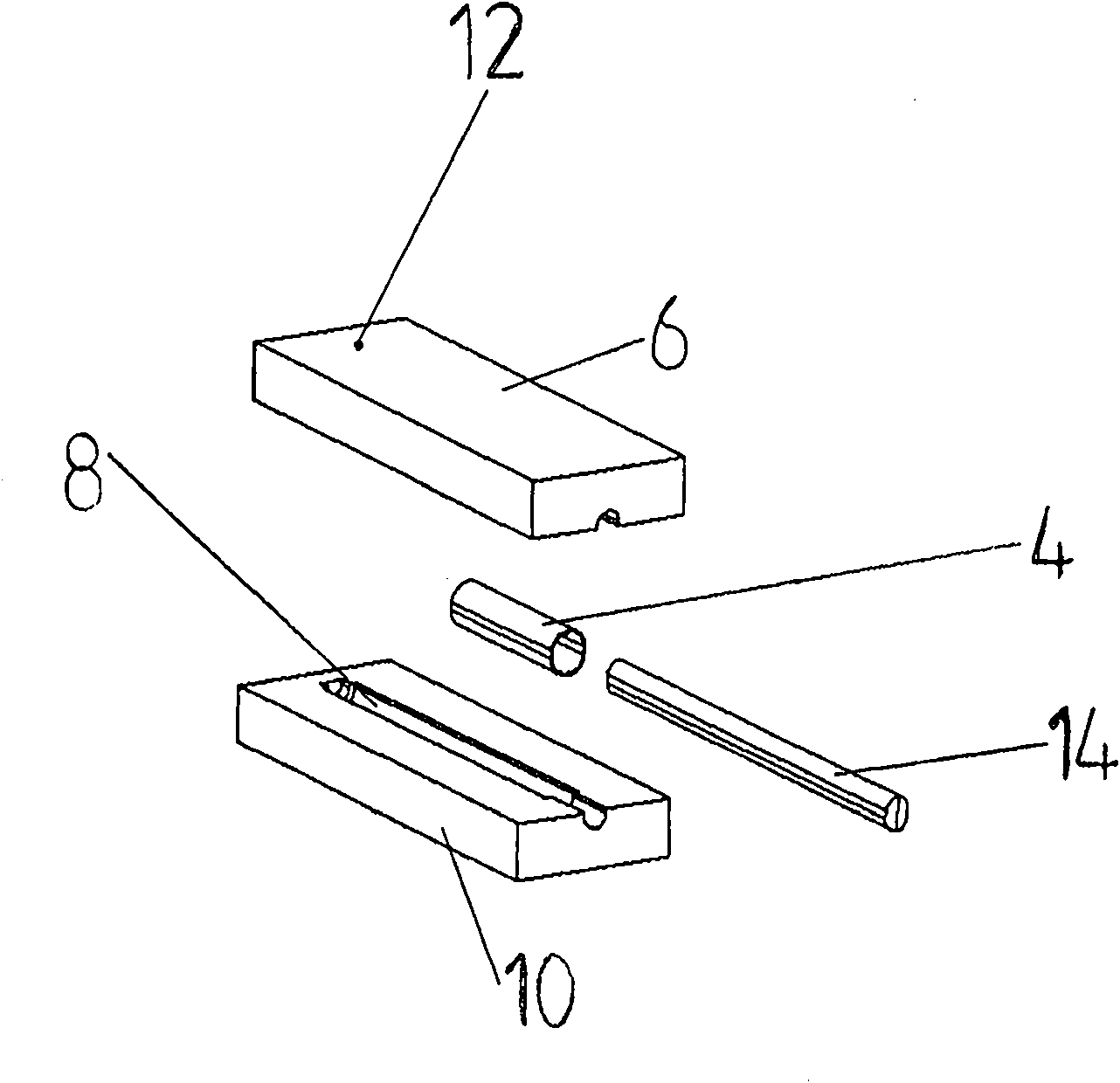

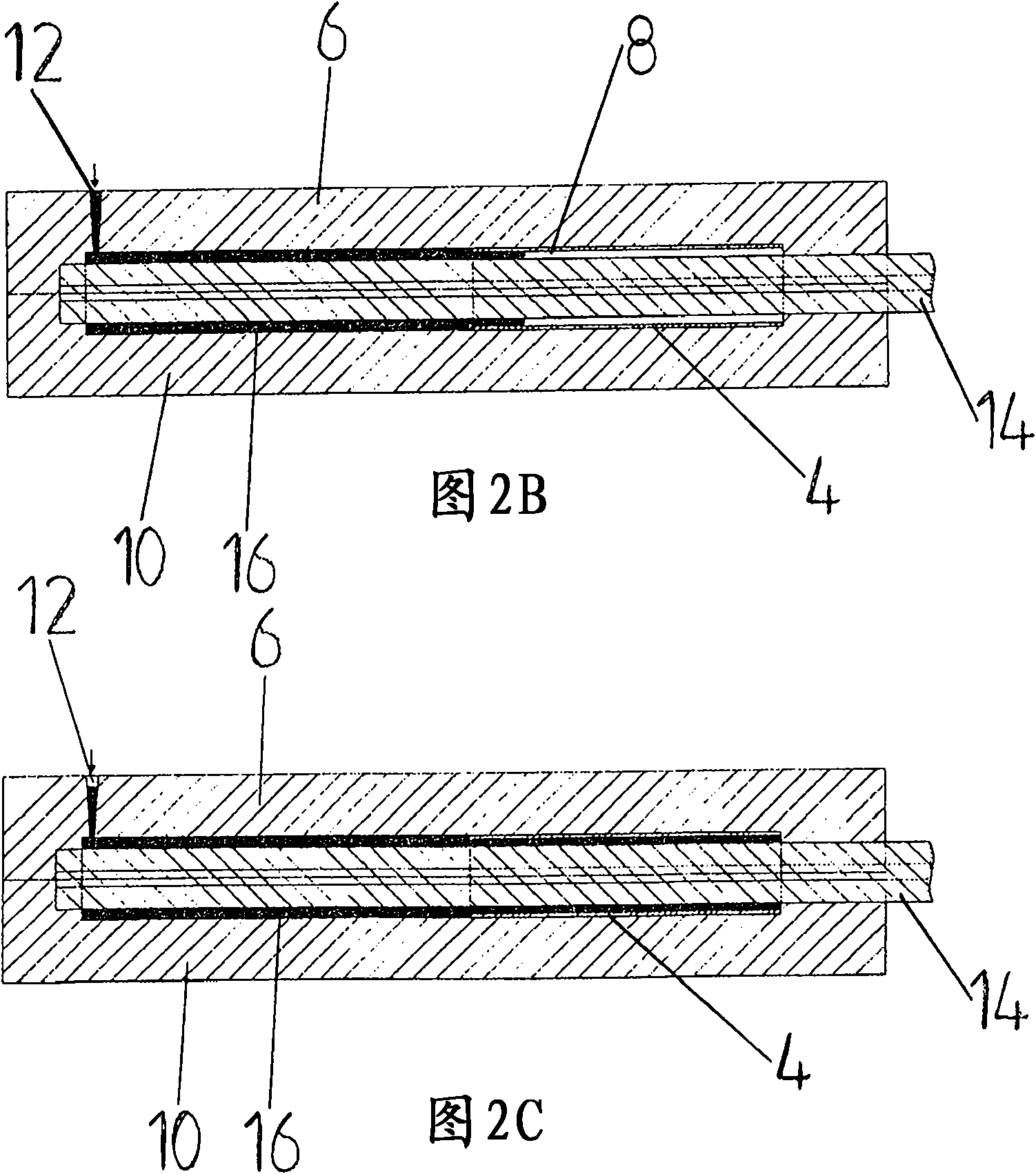

[0016] refer to figure 1 , which shows a schematic diagram of the apparatus required in the method for manufacturing the handle of the invention and the first step of the method. according to figure 1 , first make the surface part 4. The surface part 4 can be manufactured, for example, by injection molding in a separate surface part mould, or alternatively, by other molding techniques or other manufacturing methods. according to figure 1 , the surface portion 4 can be a sleeve-like or tubular part, a planar part, a strip-like part or any other part which can be arranged on the surface of the body part of the handle. The sleeve-like surface portion 4 is manufactured to at least partially surround the body portion 2 in the final product. Preferably, the surface portion 4 is a grip portion which the user holds when using the hand tool. The surface portion or grip portion 4 is preferably of a softer material than the body portion on which the surface portion is arranged.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com