Method for processing crankshaft oil holes

A processing method and crankshaft oil hole technology, applied in the field of crankshaft oil hole processing, can solve the problems of unfavorable product trial production and small batch production, high transformation cycle and cost, and large equipment investment, so as to reduce labor intensity, save working hours, and prepare short time effect

Active Publication Date: 2011-06-15

青岛淄柴博洋柴油机股份有限公司

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional processing method of crankshaft oil hole is to design special machine tools and fixtures according to the size of each crankshaft and the angle of the oil hole. The equipment investment is large and the adaptability is poor. When processing new crankshafts, the equipment renovation cycle and cost are very high, which is not conducive to product quality. Trial production and small batch production; if it is not a special machine with automatic feed control, workers need to control the feed of the drill bit at all times, and the labor intensity is very high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

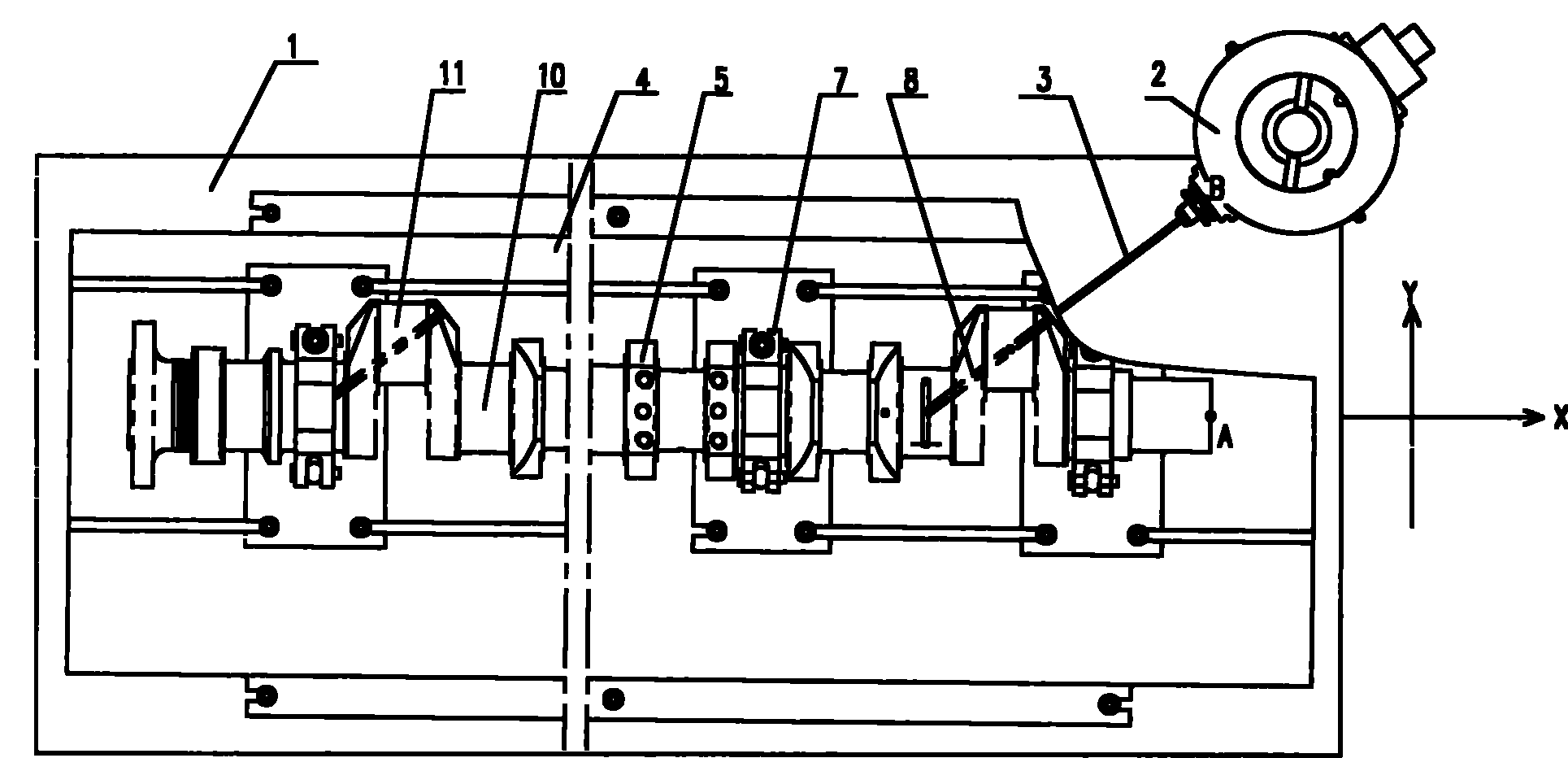

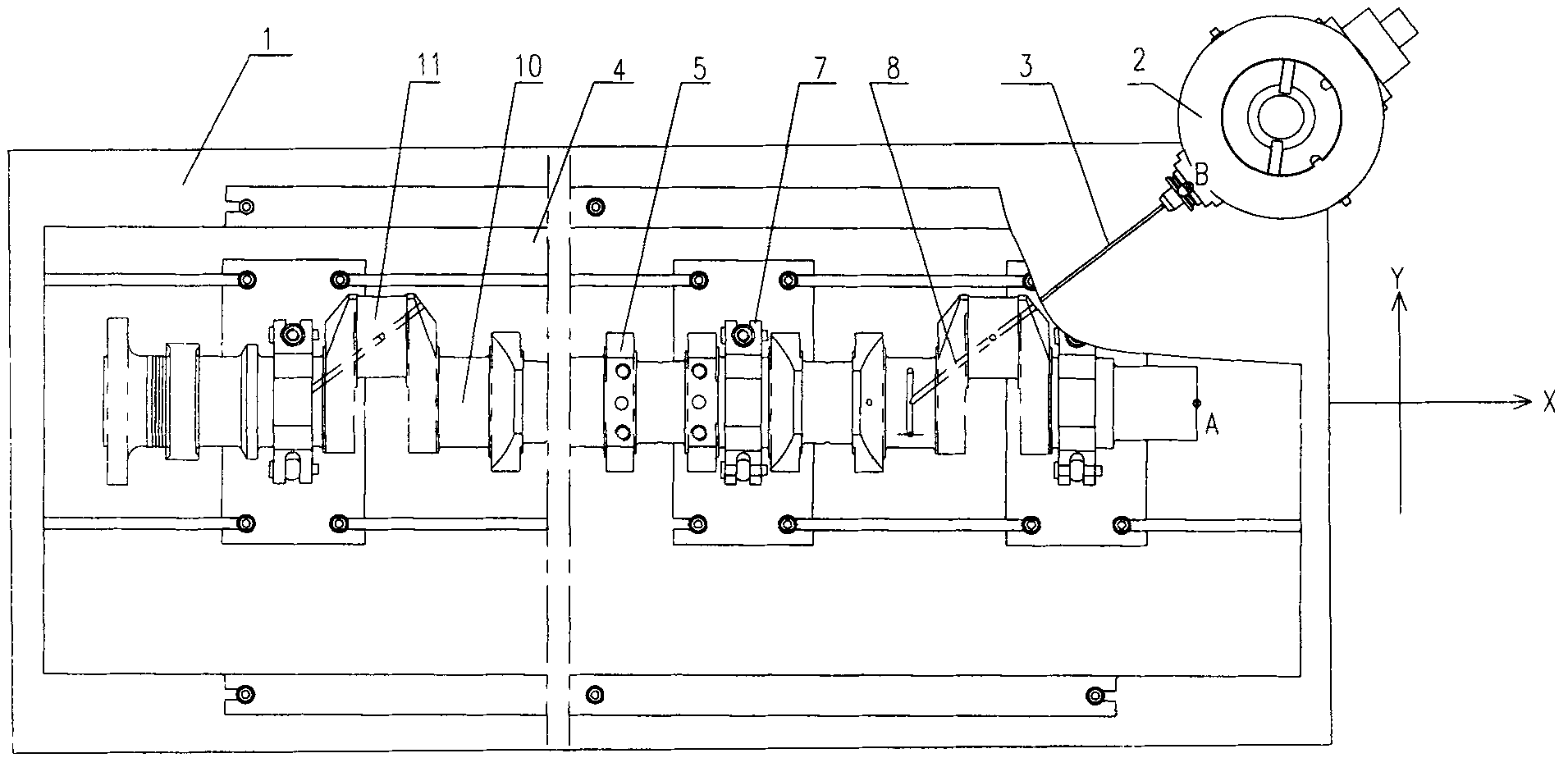

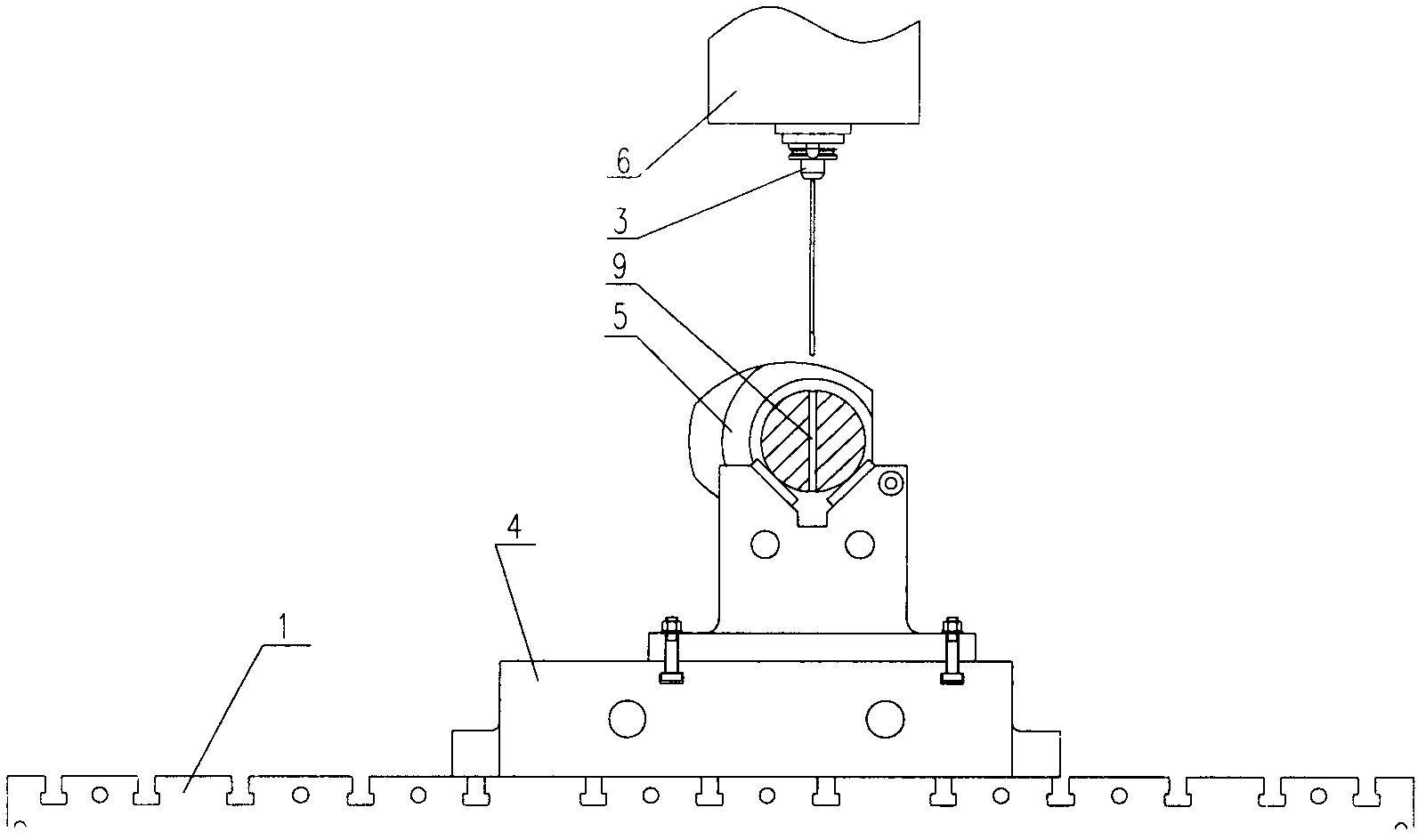

The invention discloses a method for processing crankshaft oil holes, which comprises the following steps: processing large marine crankshaft oil holes by using a numerical control plane milling and boring machine, a right-angle milling head and a crankshaft milling tool, installing a crankshaft on the crankshaft milling tool, then putting the obtained integral body on an operating platform of the numerical control plane milling and boring machine and tightly pressing the obtained integral body against the operating platform so as to form an angle alpha between the centerline of the crankshaft (on the XY plane of the numerical control plane milling and boring machine) and an X axis of the numerical control plane milling and boring machine; measuring the zero point A of a drilled straight oil hole, then drilling the straight oil hole; rotating the crankshaft so that a crank throw to be drilled is arranged in the horizontal position and fixed; rotating the right-angle milling head so as to form an included angle beta between the right-angle milling head and an axis of the numerical control plane milling and boring machine, wherein the sum of the angle alpha and the angle beta is equal to the degree of an included angle between an inclined oil hole and the central axis of the crankshaft; and offsetting the zero point, and programming so as to drill the inclined oil hole. Through adopting the technical scheme, holes with different angles can be processed without preparing special machine tools and clamps, and in the processes of trial production and small-lot production, the cost can be lowered effectively, the working hours can be saved, and the labor intensity can be reduced.

Description

Machining method of crankshaft oil hole technical field The invention relates to a method for processing an oil hole of a crankshaft, in particular to a method for processing an oil hole on a crankshaft of a medium-speed diesel engine. Background technique The traditional processing method of crankshaft oil hole is to design special machine tools and fixtures according to the size of each crankshaft and the angle of the oil hole. The equipment investment is large and the adaptability is poor. When processing new crankshafts, the equipment renovation cycle and cost are very high, which is not conducive to product quality. Trial production and small batch production; if it is not a special machine with automatic feed control, workers need to control the feed of the drill bit at all times, and the labor intensity is very high. Contents of the invention In order to overcome the above-mentioned problems existing in the prior art field, the present invention provides a fast a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P23/00

Inventor 王新叶谢庆邱前进丁晓

Owner 青岛淄柴博洋柴油机股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com