Rotating wheel paint-mist purification device

A paint mist purification and runner technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problem that the system cannot meet the requirements of continuous operation, the filter cotton cannot be regenerated, and the amount of paint mist filter cotton is used. Large and other problems, to achieve the effect of reducing consumables and operating costs, small footprint, and reducing air conditioning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

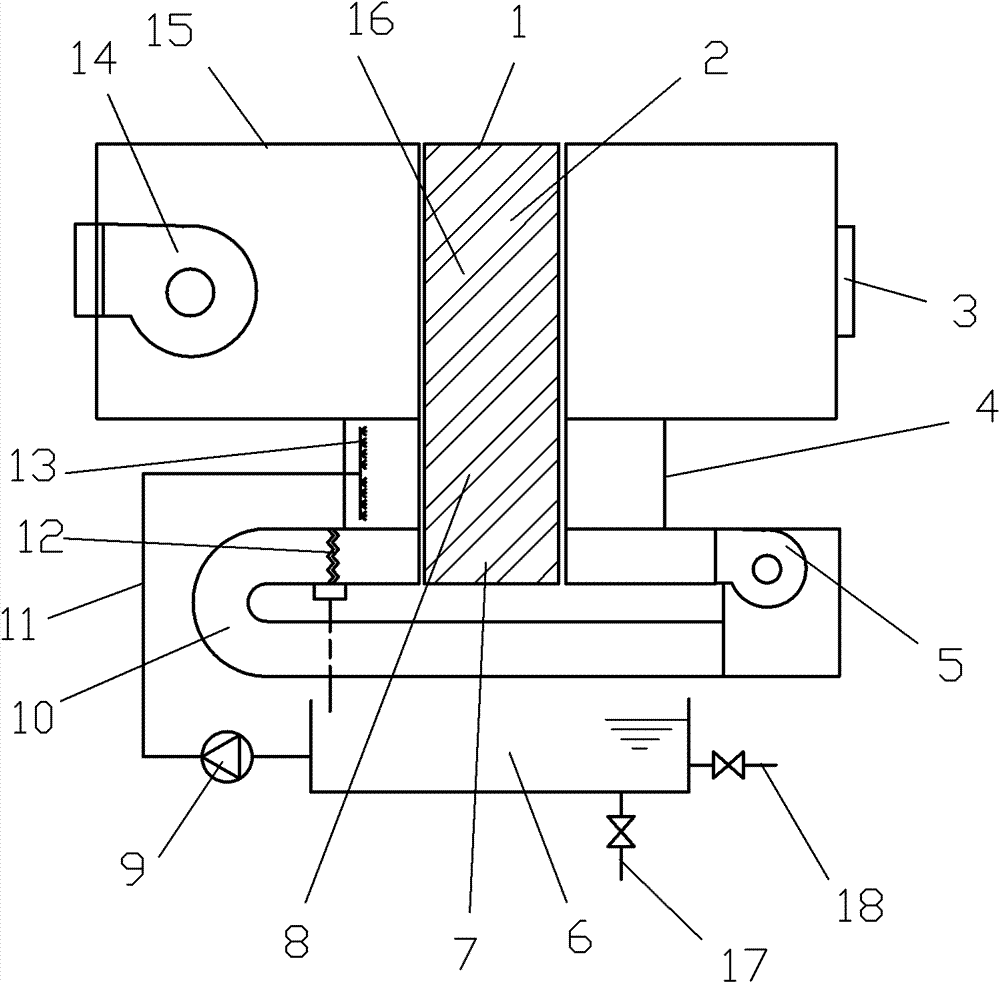

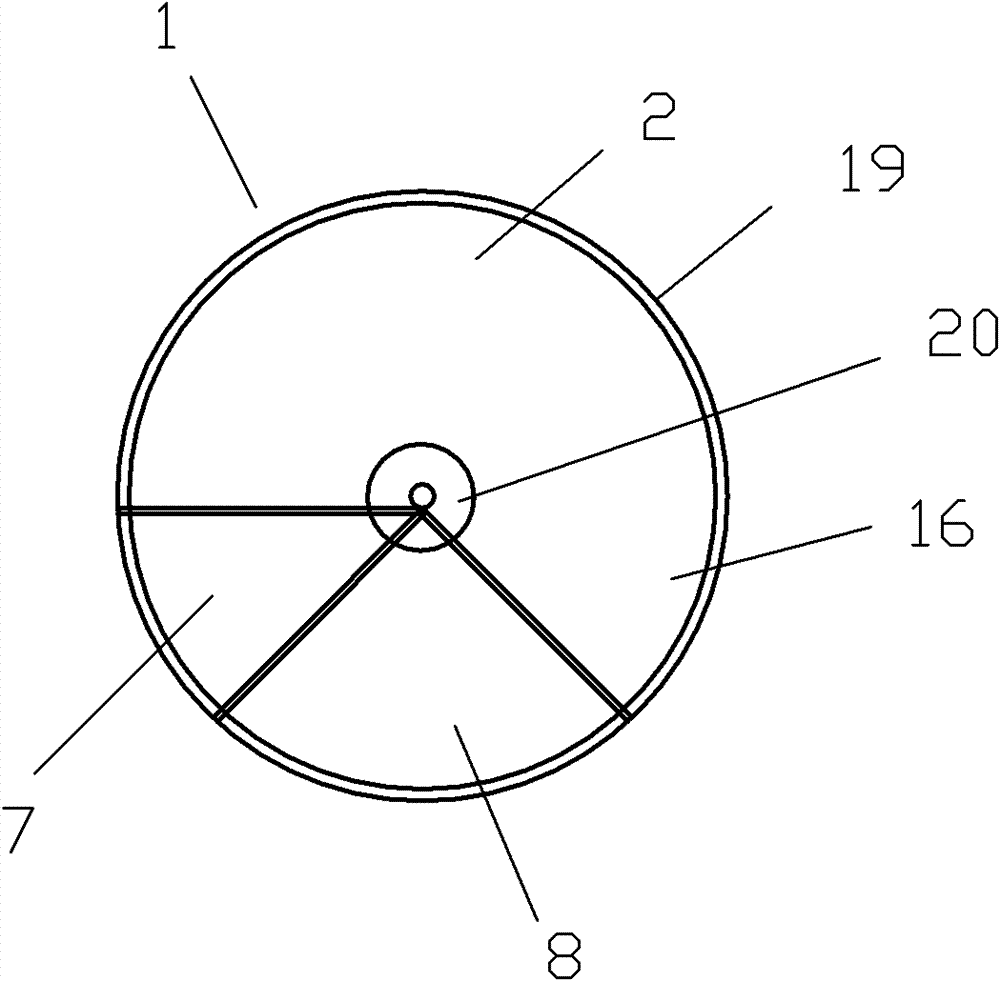

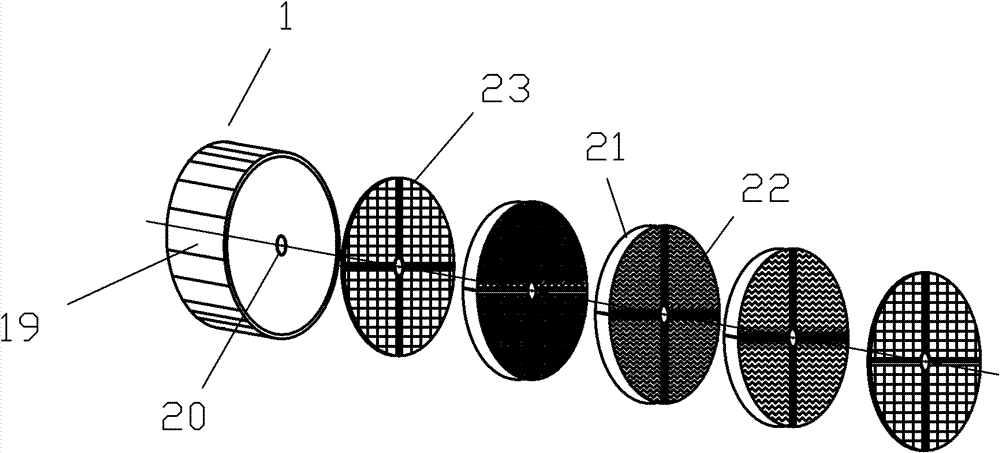

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 , a kind of wheel paint mist purifying device provided by the present invention, the upper part of the wheel 1 driven by the electric mechanism forms a filter area 16 with an exhaust mechanism, and forms a cleaning area 8 with a cleaning mechanism downstream along the direction of rotation, and a drying area. The mechanism forms a drying area 7; the runner 1 includes a casing 19 on the outer periphery, a shaft sleeve 20 for installing the central shaft, and a medium layer 2 installed between the casing 19 and the shaft sleeve 20. The medium layer 2 forms a layered shape according to the direction of the air to be filtered. Each layer is arranged with a certain gap by wavy metal plates 22 or plastic plates to form a mesh structure, and the metal plates 22 or 22 are layered along the air direction. The plastic plate forms the air circulation channel from sparse to dense. The above-mentioned metal plate 22 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com