Simple line spanning frame

A technology of spanning racks and lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient traffic and residents' life, high work intensity of construction personnel, and the arc of the spanning line cannot be reached, and can increase the height of the side bar and the spanning bar. The effect of length, reduction of cross labor intensity, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

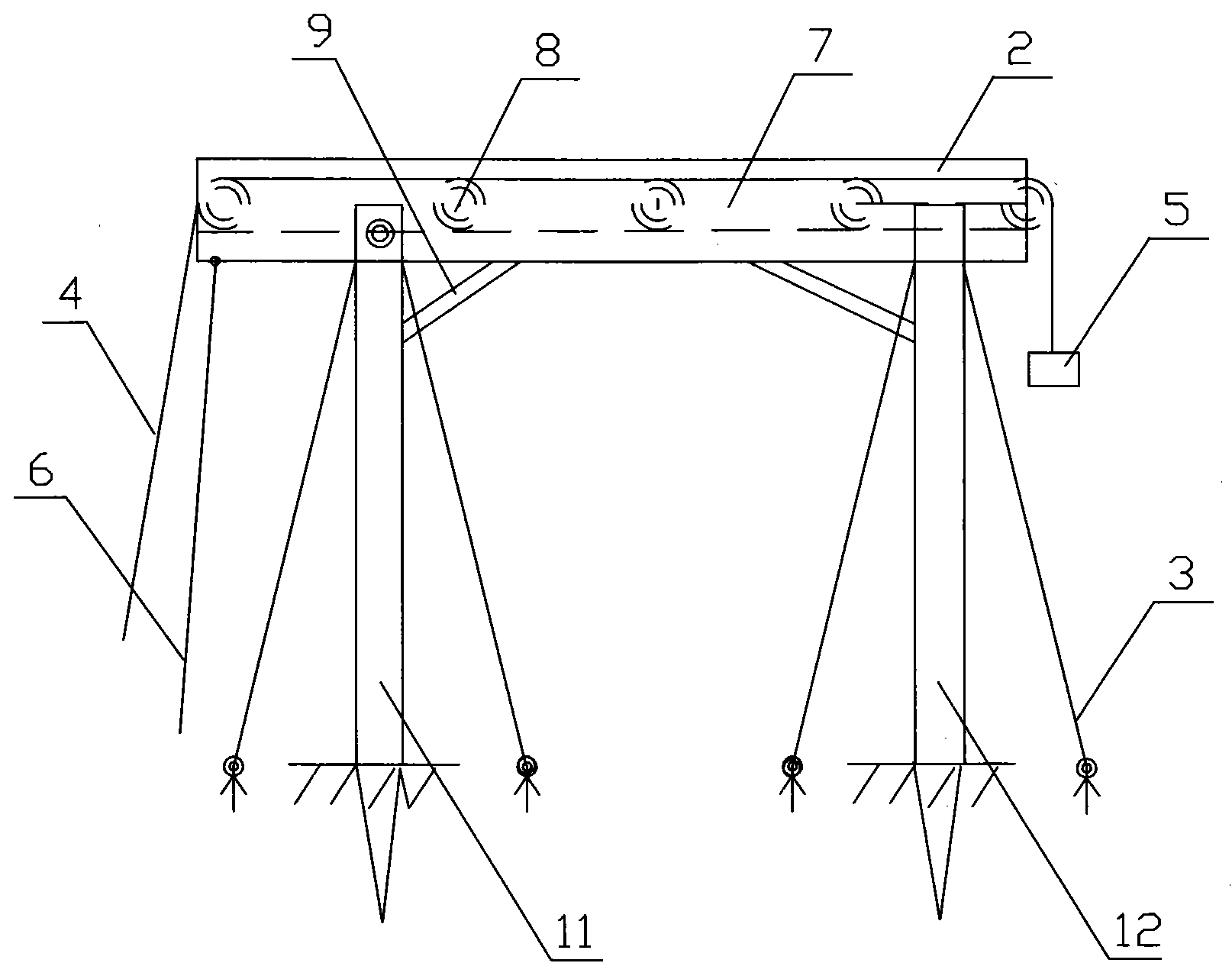

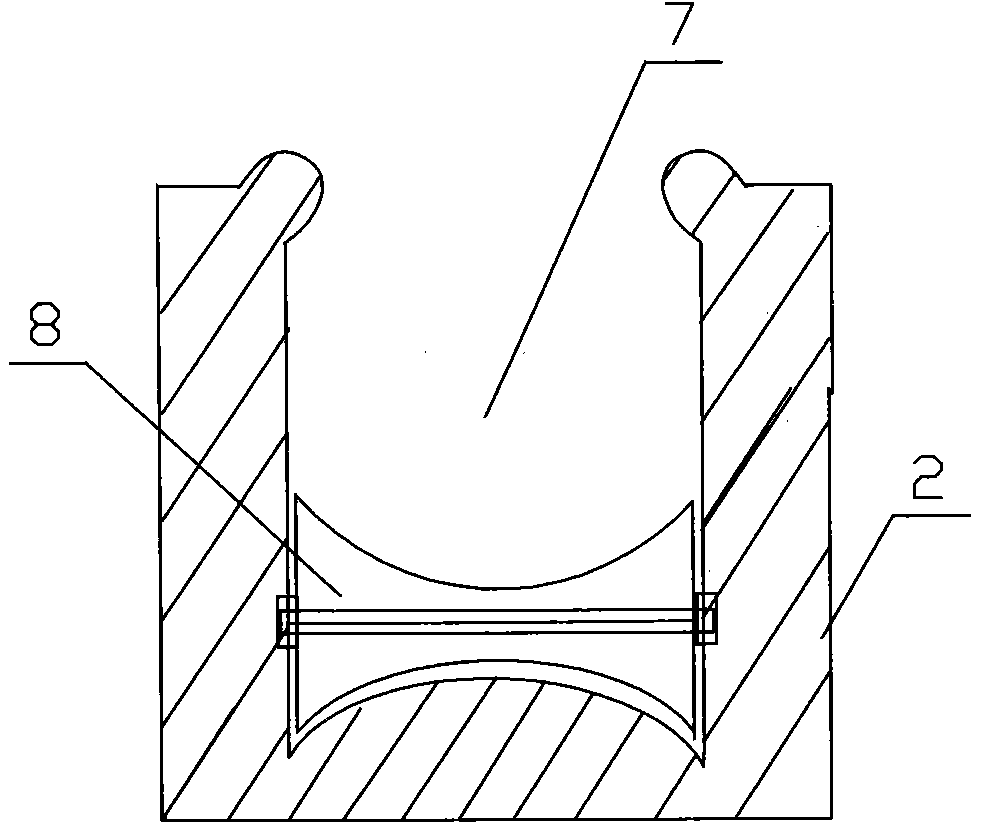

[0010] like figure 1 As shown, a simple line spanning frame includes two uprights 11, 12 and a spanning rod 2, the spanning bar 2 is axially connected with one of the uprights 11, and is connected with the other upright 12 in a card-type manner. A fixed pull wire 3 is arranged on the uprights 11 and 12, a long groove 7 is longitudinally arranged on the upper surface of the spanning rod 2, a plurality of pulleys 8 are arranged in the long groove 7, and a pull wire 4 is arranged on the pulley 8 to pass through the span The rod slot 7 extends out of the spanning rod 2 , one end of the traction wire 4 is provided with a counterweight 5 , and one end of the spanning rod 2 that is axially connected with the upright column 11 is provided with a pulling rope 6 .

[0011] A support rod 9 is arranged between the upright columns 11 and 12 and the spanning rod 2 .

[0012] When using, assemble the side column 11 and the spanning rod 2, put the traction wire 4 and the connected counterwei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com