Wind power gas compressor

A compressor and wind technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of difficult maintenance by maintenance personnel, inability to operate at full load, and difficulty for cranes to reach the site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

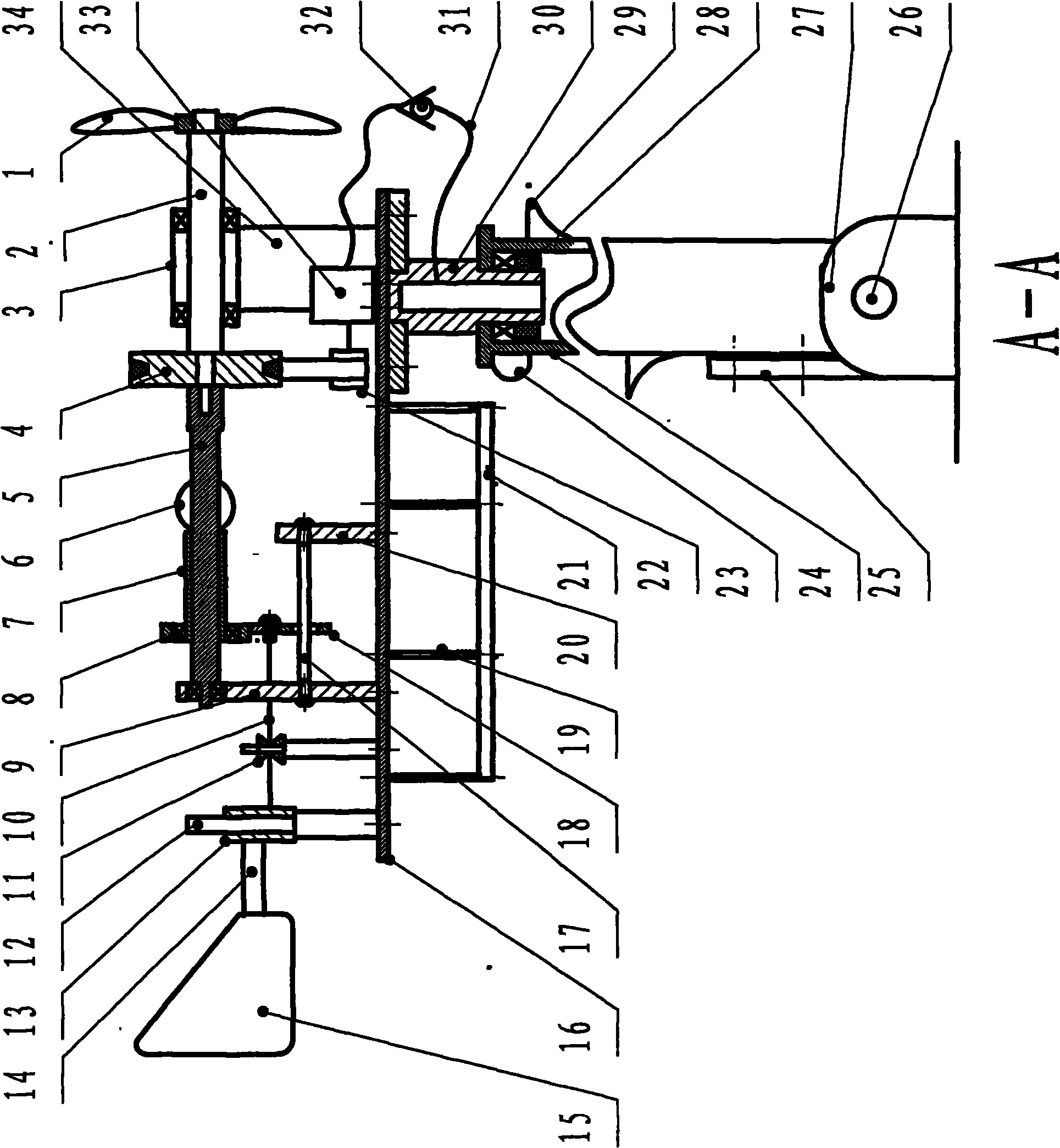

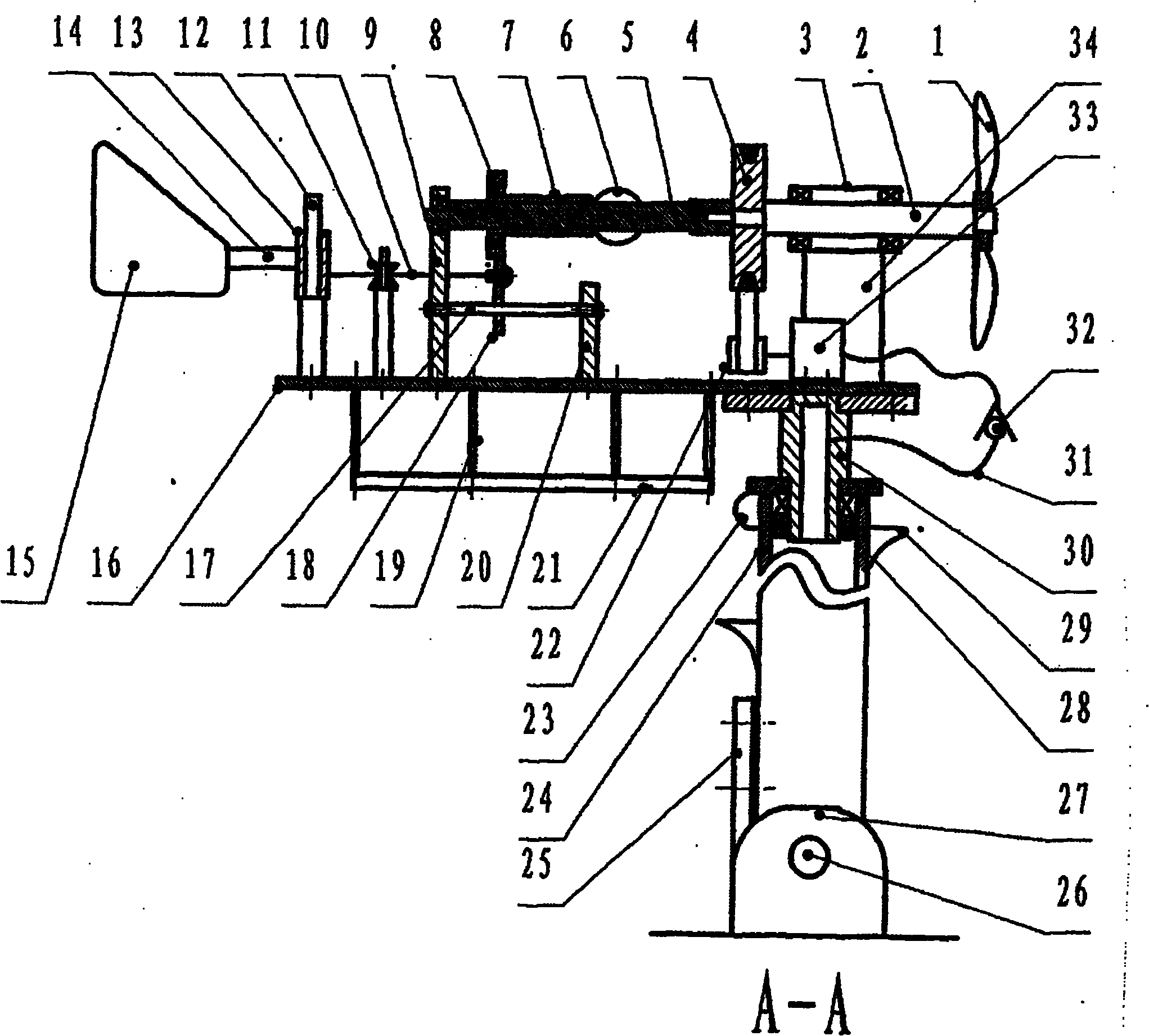

[0016] From figure 1 , 2 It can be seen from the illustrated embodiment that this embodiment includes a support system and an air compressor system, and is characterized in that it also includes a wind power mechanism, an empennage and its limit mechanism, and a centrifugal speed limiting mechanism; the wind power mechanism includes fan blades 1. Horizontal rotating shaft, support platform 16 and tubular vertical rotating shaft 30; the horizontal rotating shaft is composed of the power shaft 2 and the centrifugal shaft 5 fixedly connected with it, and the two ends of the horizontal rotating shaft are respectively installed on the left and right supporting bases through bearings 9, 34, the left and right support bases 9, 34 are fixed on the support platform 16, the fan blade 1 is fixed on one end of the power shaft 2, and the tubular vertical shaft 30 passes through the flange at its upper end fixed on the bottom surface of the right end of the support platform 16;

[0017] D...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap