Method for recording temperature curve in heavy rail steel billet heating process

A temperature curve and billet heating technology, applied in heat treatment process control, thermometers, thermometer parts, etc., can solve the problem of not being able to display the temperature curve, not being able to realize the optimization control of the furnace temperature setting value, and not being able to reflect the heating temperature of the heavy rail billet And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

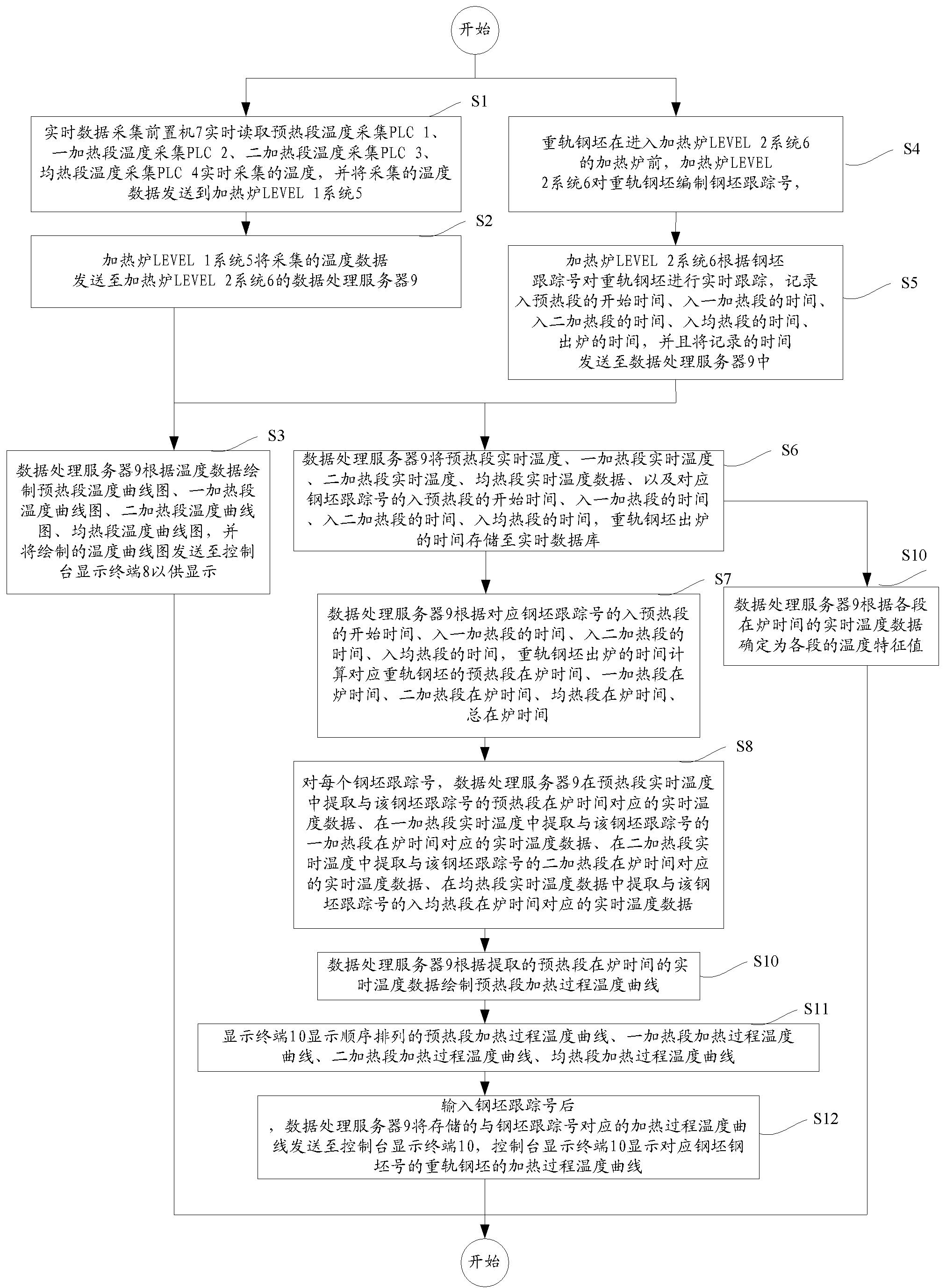

[0043] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

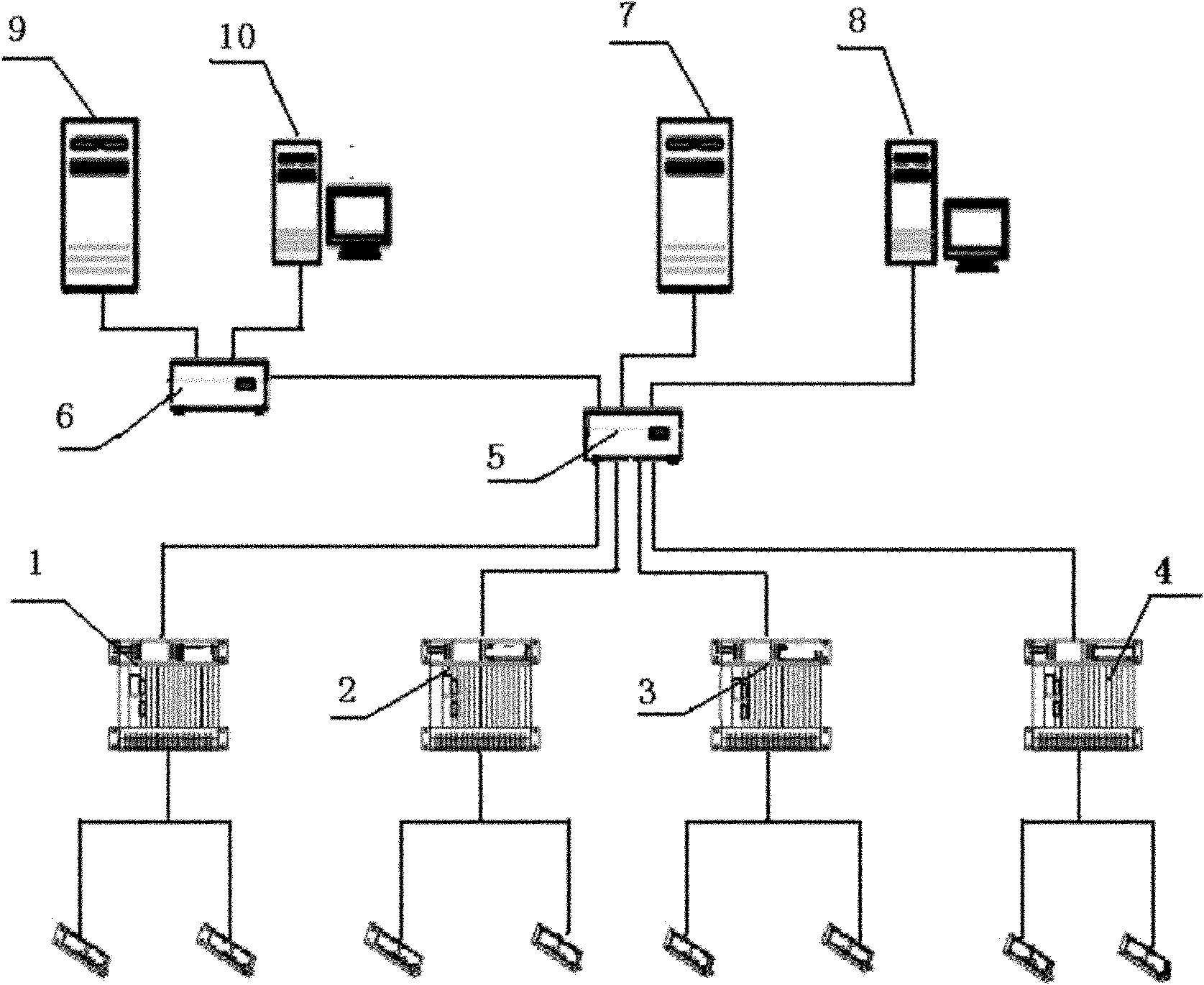

[0044] Such as figure 2 The hardware involved in the method for recording the temperature curve of the heating process of the heavy rail billet of the present invention includes: PLC 1 for temperature acquisition in the preheating section, PLC (programmable controller) 2 for temperature acquisition in the first heating section, PLC 3 for the temperature acquisition in the second heating section, and a soaking section Temperature acquisition PLC 4, heating furnace LEVEL 1 (first-level network system) system 5, heating furnace LEVEL2 system (secondary network system) 6, temperature acquisition front-end processor 7, console terminal 8, data processing server 9, display terminal 10 .

[0045] The heating furnace LEVEL 1 system 5 and the preheating section temperature acquisition PLC 1, the first heating section temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com