Pneumatic tire

A technology for pneumatic tires and carcasses, which is applied to the reinforcement layers, tire parts, tire edges and other directions of pneumatic tires, can solve problems such as poor ride comfort, and achieve the effect of superior ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

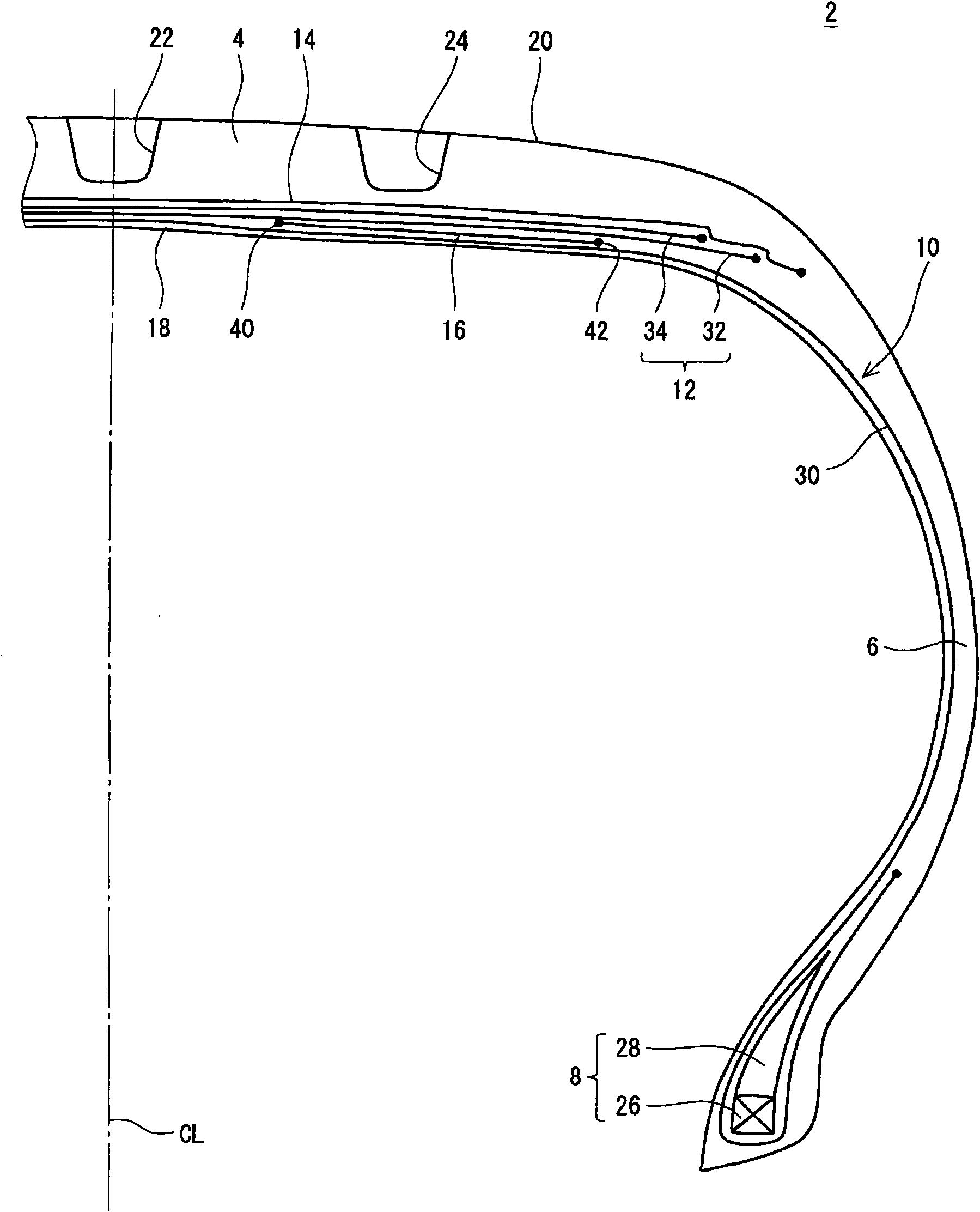

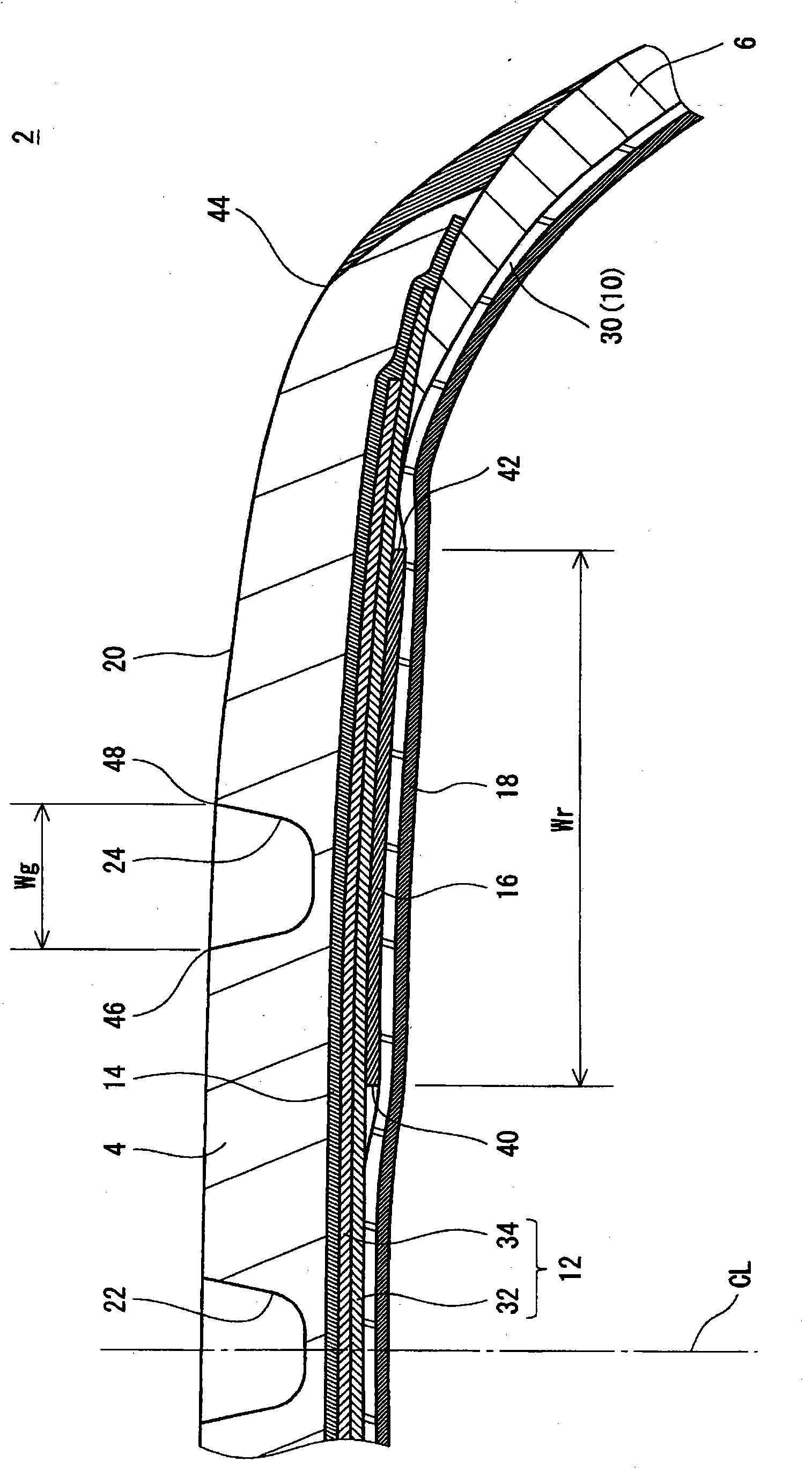

[0066] made Figure 1 to Figure 4 Said structure of the passenger car tires. The size of this tire is "195 / 65R15". The specifications of this tire are as follows.

[0067] Tread

[0068] Main groove width Wg: 8mm

[0069] Carcass

[0070] Cord Material: Nylon

[0071] Cord fineness: 1670 dtex / 2

[0072] The angle of the cord relative to the circumferential direction: 90°

[0073] belt layer

[0074] Cord Material: Steel

[0075] The composition of the cord: 2+2

[0076] Cord wire diameter: 0.23mm

[0077] The angle of the cord relative to the circumferential direction: 26°

[0078] belt layer

[0079] Cord Material: Nylon

[0080] Cord fineness: 1400 dtex / 2

[0081] The angle of the cord relative to the circumferential direction: about 0°

[0082] reinforcement layer

[0083] Cord Material: Steel

[0084] The composition of the cord: 2+2

[0085] Cord wire diameter: 0.23mm

[0086] The angle of the ...

Embodiment 2~8

[0089] Tires of Examples 2 to 8 were obtained in the same manner as in Example 1 except that the width Wr was set as shown in Table 1 below.

Embodiment 9~14

[0095] Tires of Examples 9 to 14 were obtained in the same manner as in Example 1 except that the position of the reinforcing layer was set as shown in Table 2 below. The meanings of symbols (A) to (E) in Table 2 are as follows.

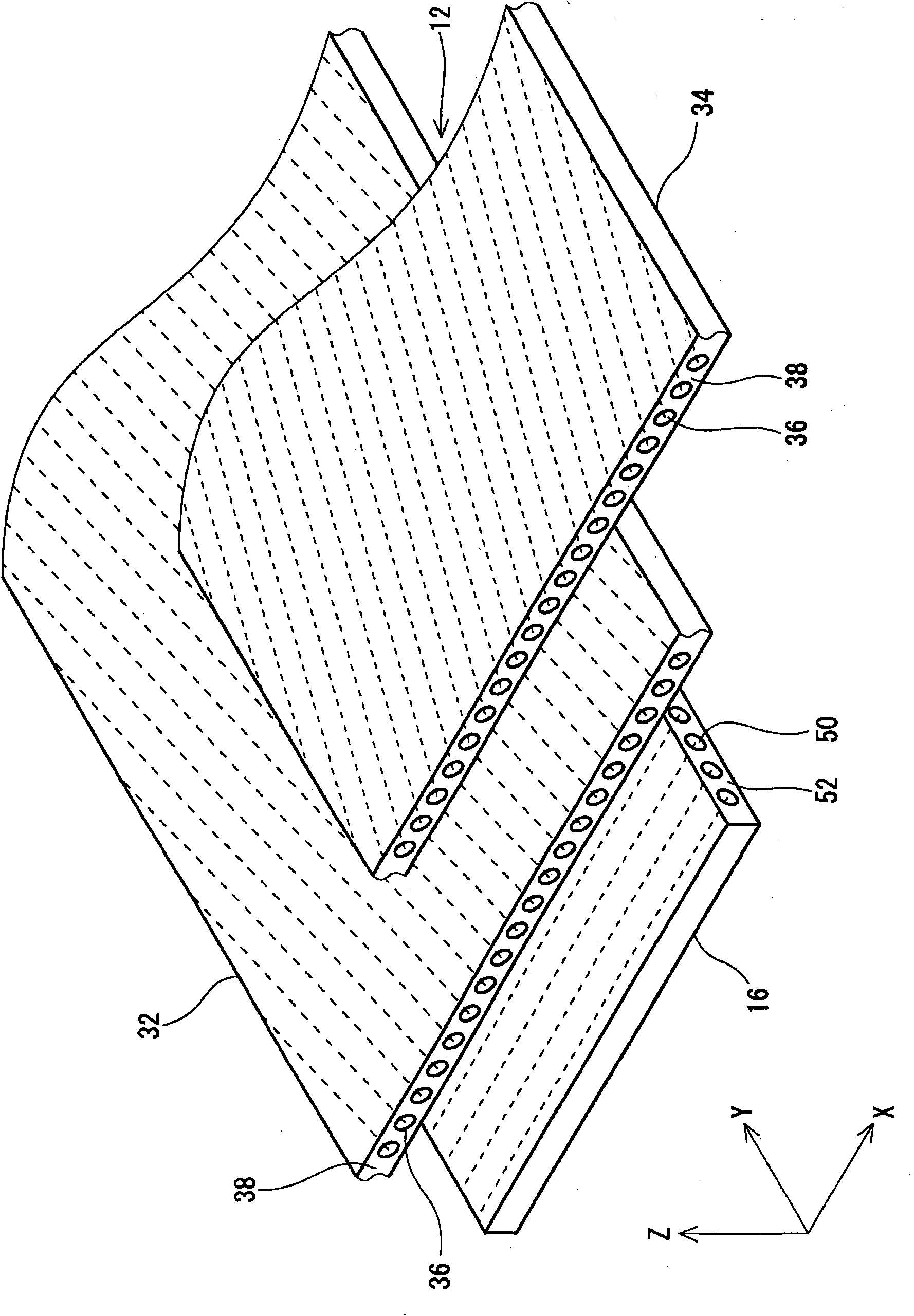

[0096] (A) Between the carcass 10 and the belt 12

[0097] (B) Between the inner liner 18 and the carcass 10

[0098] (C) Between the inner layer 32 of the belt layer 12 and the outer layer 34 of the belt layer 12

[0099](D) Between the belt layer 12 and the belt layer 14

[0100] (E) Between the belt layer 14 and the tread portion 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com