Rubber punching machine

A punching machine and rubber technology, applied in metal processing and other directions, can solve problems such as affecting punching efficiency, and achieve the effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

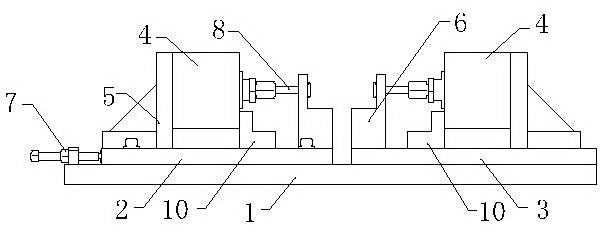

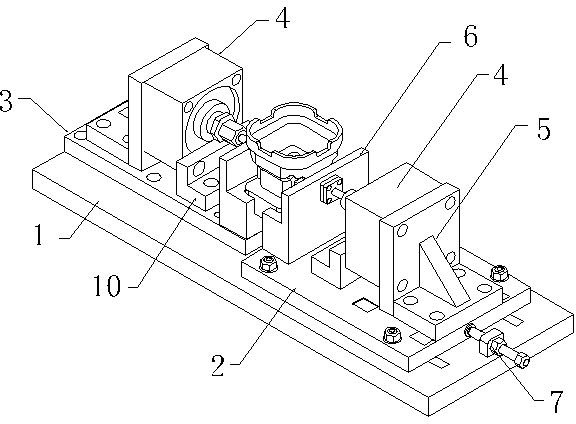

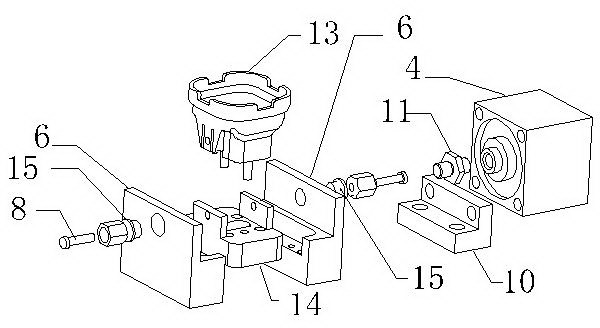

[0019] Example: A rubber punching machine of this example is figure 1 , 2 As shown, it includes a machine base plate 1, on which a product fixing seat is installed, and a left punching base plate 2 and a right punching base plate 3 installed opposite each other, and punching devices are installed on both the left punching base plate 2 and the right punching base plate 3 And the product fixing seat, the punching device includes a cylinder 4 and a punch 8. The axis lines of the punch 8 on the left punching base plate 2 and the punch 8 on the right punching base plate 3 coincide with each other. The split seat 6 is installed on the left punch bottom plate 2 and the right punch bottom plate 3. The split seat 6 is stepped. The lower step surface of the split seat 6 is provided with a concave mounting part, and the mounting part is provided with a screw Holes, such as image 3 As shown, there is a punch hole on the stepped wall of the split seat 6, a punch guide sleeve 15 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com