Leakage detecting method for urban water supply pipes

A detection method and technology of water supply pipe network, which are applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of sound signal detection capability, signal filtering and processing methods are not optimized, cost is high, and leakage recorders are false alarms. and other problems to achieve the effect of reducing the workload of investigation, improving work efficiency, and accurately locating missing points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

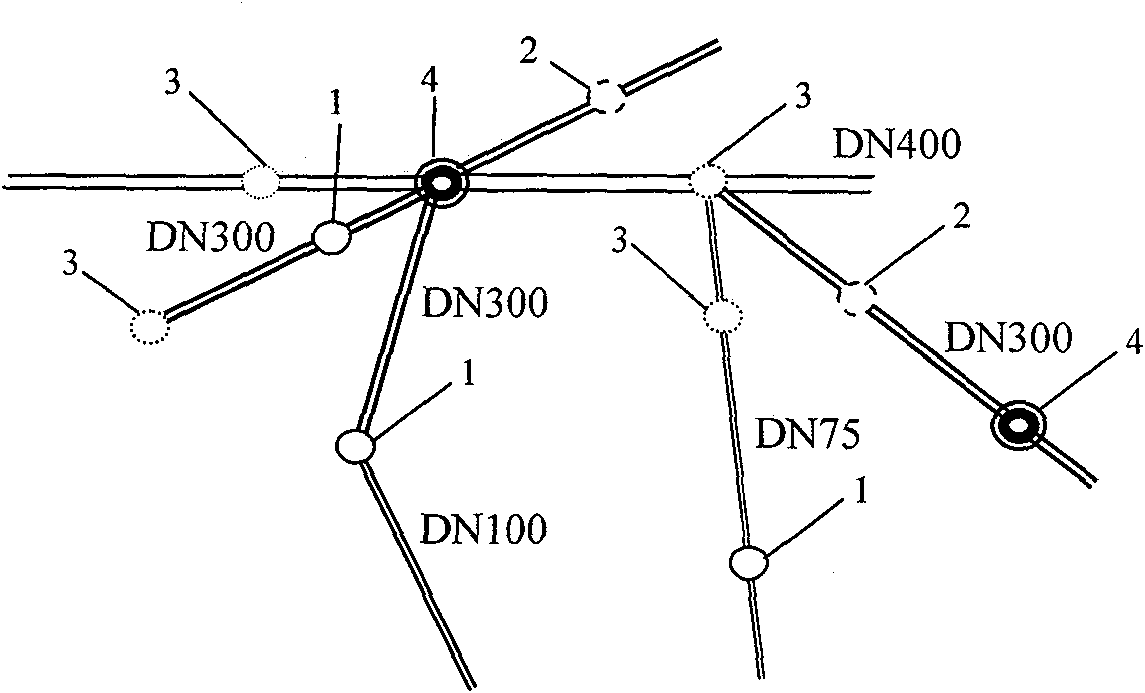

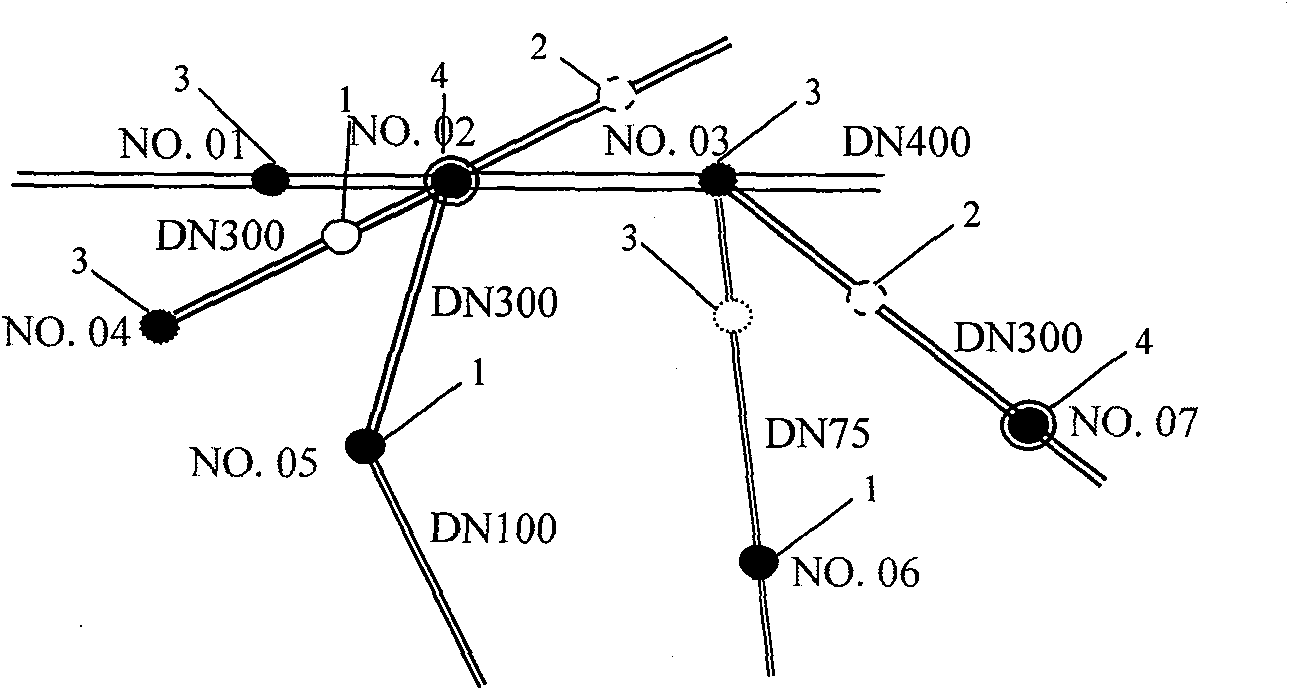

[0028] Leakage recorder layout: request to figure 1 The pipe network in the indicated area is tested for leaks. According to the layout principle of loss recorder, for DN75mm and DN100mm pipelines, the distance of the loss recorder is between 150m and 200m; for DN300mm pipelines, the distance of the loss recorder is between 100m and 150m; for pipelines of DN400mm and above , The distance of the leakage recorder is between 60m and 100m. Leakage recorders should be preferentially installed in accessories such as inspection wells, fire hydrants, exhaust valves, valves, and gates. Use the distance calculation function of GIS and its optimized calculation method to lay out the missing recorder, the layout result is as follows figure 2 Shown.

[0029] Leakage recorder layout and signal collection: GIS is deployed according to the loss recorder figure 2 The position shown for the leakage recorder layout. On the second day after the installation was completed, the signal of the los...

Embodiment 2

[0033] Leakage recorder layout: request to figure 1 The pipe network in the indicated area is tested for leaks. According to the layout principle of loss recorder, for DN75mm and DN100mm pipelines, the distance of the loss recorder is between 150m and 200m; for DN300mm pipelines, the distance of the loss recorder is between 100m and 150m; for pipelines of DN400mm and above , The distance of the leakage recorder is between 60m and 100m. Leakage recorders should be preferentially installed in accessories such as inspection wells, fire hydrants, exhaust valves, valves, and gates. Use the distance calculation function of GIS and its optimized calculation method to deploy the missing recorder, the results of the layout are as follows figure 2 Shown.

[0034] Leakage recorder layout and signal collection: GIS is deployed according to the loss recorder figure 2 The position shown for the leakage recorder layout. On the second day after the installation was completed, the signal of...

Embodiment 3

[0039] Leakage recorder layout: request to figure 1 The pipe network in the indicated area is tested for leaks. According to the layout principle of loss recorder, for DN75mm and DN100mm pipelines, the distance of the loss recorder is between 150m and 200m; for DN300mm pipelines, the distance of the loss recorder is between 100m and 150m; for pipelines of DN400mm and above , The distance of the leakage recorder is between 60m and 100m. Leakage recorders should be preferentially installed in accessories such as inspection wells, fire hydrants, exhaust valves, valves, and gates. Use the distance calculation function of GIS and its optimized calculation method to deploy the missing recorder, the results of the layout are as follows figure 2 Shown.

[0040] Leakage recorder layout and signal collection: GIS is deployed according to the loss recorder figure 2 The position shown for the leakage recorder layout. After the installation was completed, the signal collection of the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com