T-type groove mechanical pile extension structure for prefabricated square pile and construction method

A technology of machinery and end plates, applied in the field of structural connection of uplift-resistant foundation piles, can solve problems such as reducing the quality of pile connections, affecting construction efficiency, and hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

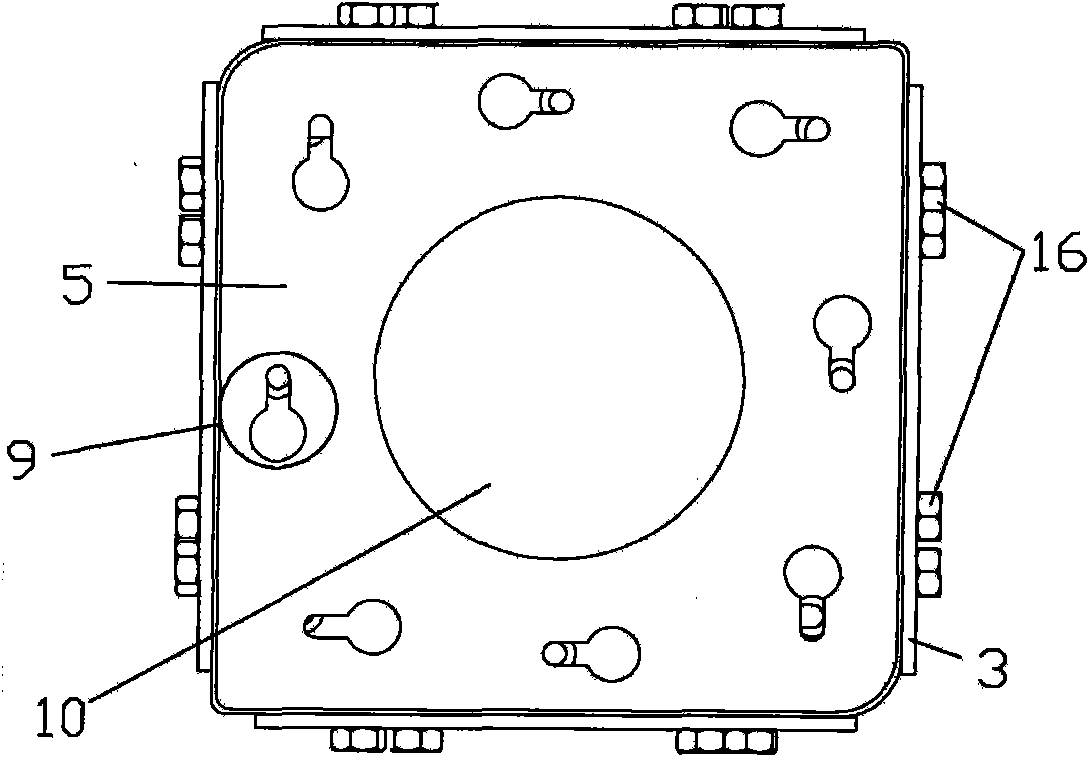

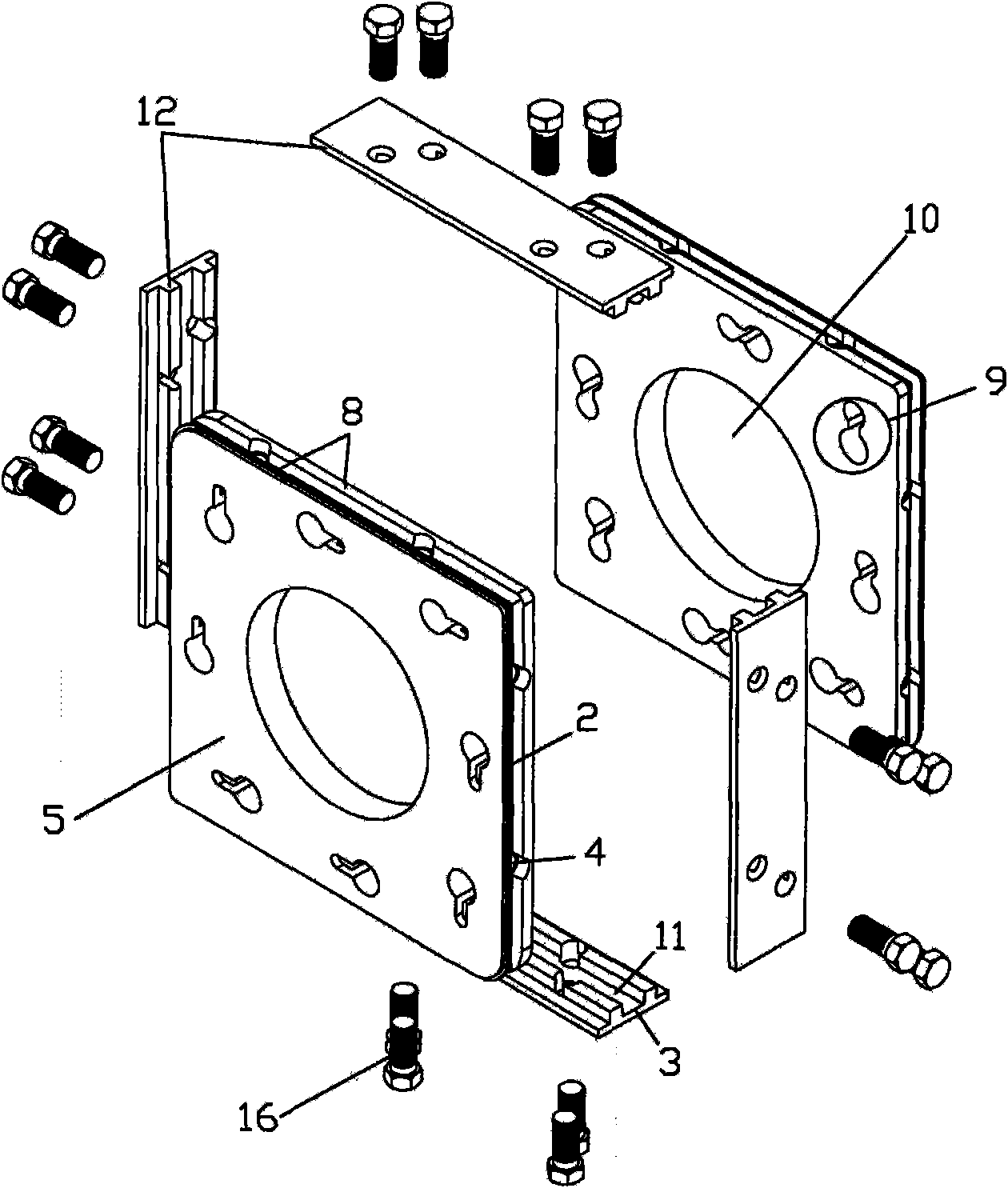

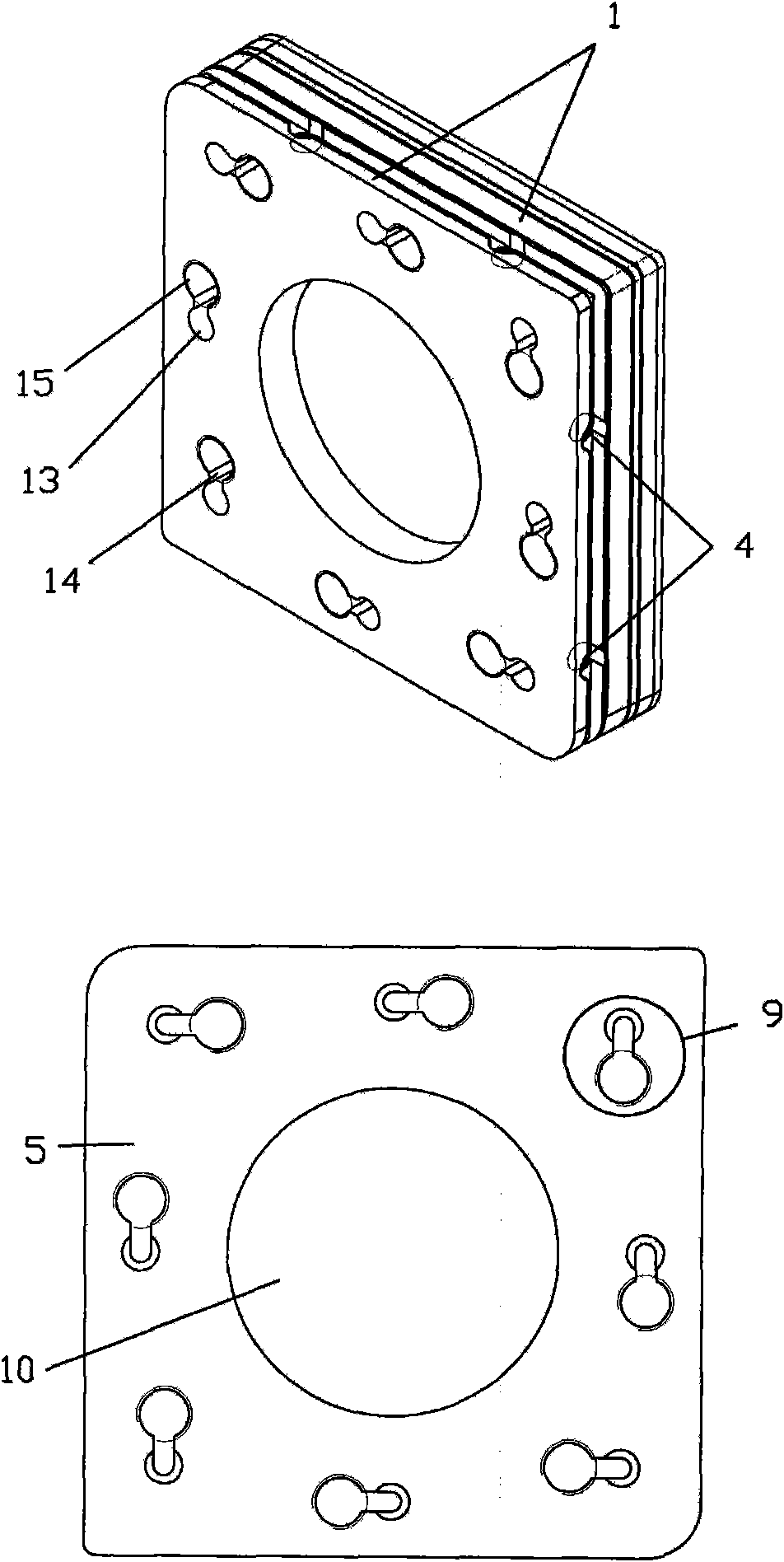

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0025] see Figure 1-Figure 4 , a T-slot mechanical pile connection structure for prefabricated square piles, mainly composed of a prefabricated square pile end plate 1 and a trapezoidal card body 3, when two prefabricated square piles are docked, use the trapezoid on the side of the two prefabricated square pile end plates The groove 2 is engaged with the four trapezoidal clamping bodies 3 connected outside, and then the trapezoidal clamping body and the screw holes 4 at the end plate groove 2 are screwed and connected by bolts 16 to ensure the connection and fixation of the two piles.

[0026] The end plate 1 in this mechanical connection structure consists of a rib plate 5, a clamp mouth 6 provided on the surface of the rib plate 5, a pile ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com