Capacity adjustment device of rotary bottle blowing die

A capacity adjustment and bottle blowing mold technology, applied in the field of rotary bottle blowing mold capacity adjustment devices, can solve the problems of bottle expansion, high cost of re-opening the mold, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

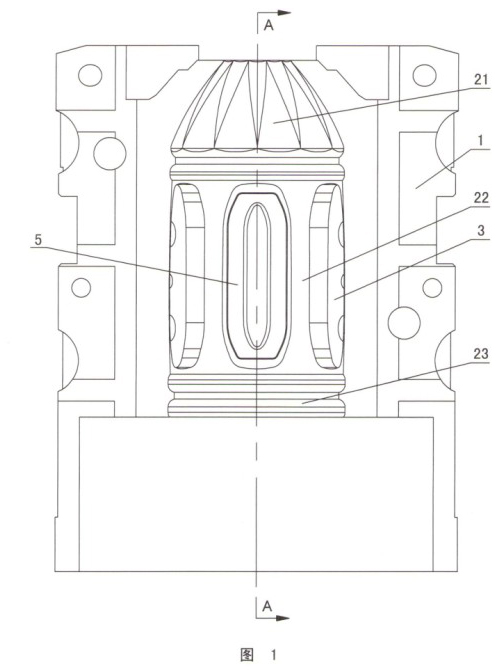

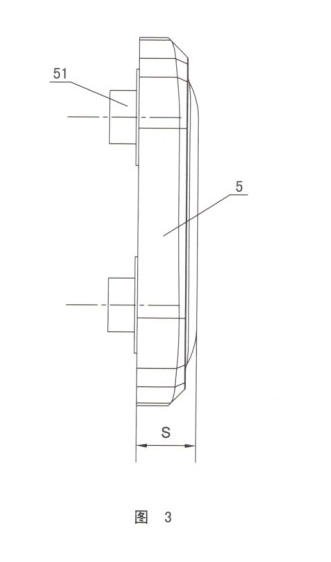

[0010] The invention relates to a rotary blowing mold capacity adjustment device, such as Figure 1-Figure 3 As shown, the bottle blowing mold 1 is included, the bottle blowing mold is divided into left and right parts, a bottle-shaped cavity is opened in the blowing mold, and the bottle-shaped cavity is divided into an upper part 21, a middle part 22 and a lower part 23, which is characterized in that the A capacity adjustment groove 3 is formed on the wall of the middle part 22 of the bottle-shaped mold cavity, and a fixing hole 4 is opened in the capacity adjustment groove. The bolt 6 is fixed with the capacity adjusting groove 3 . A capacity adjustment groove 3 is formed on the inner wall of the middle part 22 of the mold cavity, a capacity adjustment block 5 is installed in the capacity adjustment groove, and the capacity adjustment block is fixed in the capacity adjustment groove by bolts 6. When a bottle with a larger capacity is to be produced, As long as the capacity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com