Lower press plate used by flat bed guide rail of machine tool

A technology of flat bed and pressure plate, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of increased use cost, time-consuming and laborious, and reduced shock resistance of moving parts, so as to prolong the service life and reduce the use of cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

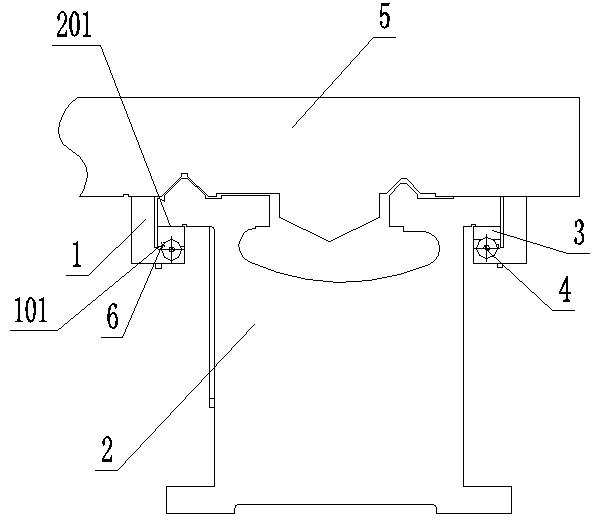

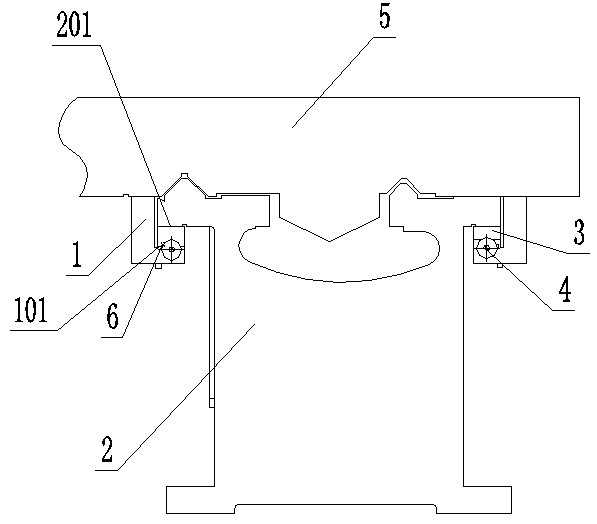

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

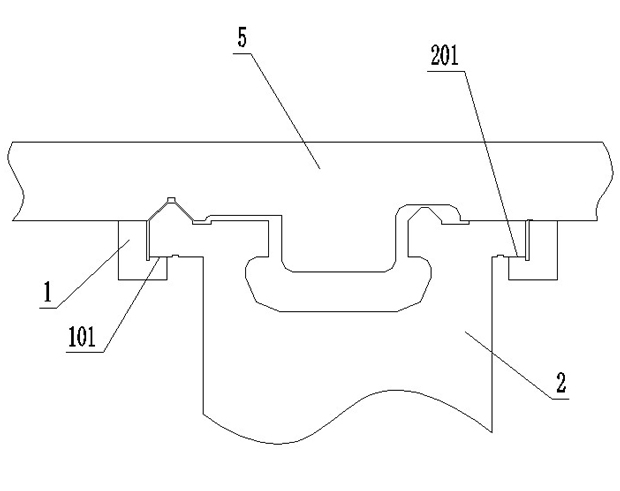

[0013] See attached figure 2 , the lower platen for the guide rail of the flat bed of the machine tool in the figure includes a platen seat 1 and a platen surface 101 arranged on the platen seat 1 to cooperate with the lower surface of the machine bed, wherein: the platen surface 101 is provided with inclined inserts 3, inclined The inlay 3 is connected to the platen seat 1 through the double-headed adjusting bolt 4 passing through the platen seat 1 . During use, the bevel insert 3 is wedge-shaped, the big end is outside, and the small end is installed inside. By adjusting the double-ended adjusting bolt 4, the worn bevel insert 3 is directly adjusted to the Z of the machine tool, and adjusted to the factory precision of the machine tool. until.

[0014] The oblique insert described in this embodiment is provided with a forced lubrication hole 6 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com