Bush fixture

A fixture and set technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficult to control the depth of pressing force and damage to parts, so as to improve assembly efficiency and accuracy, and ensure press-fitting. Accuracy, ensure the effect of controlling the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

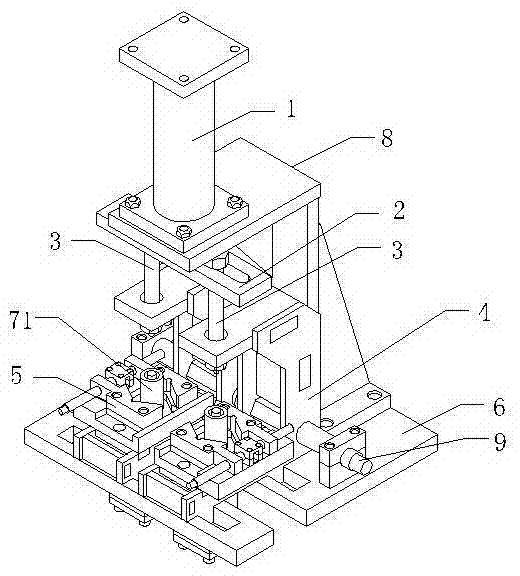

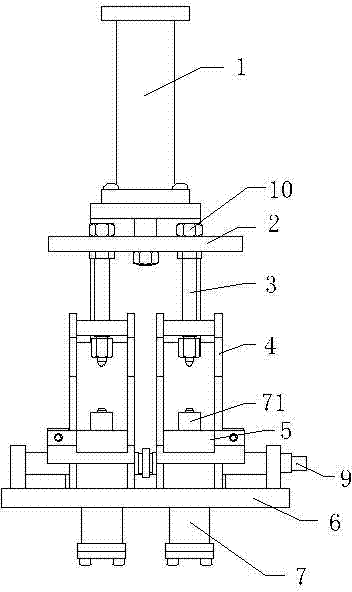

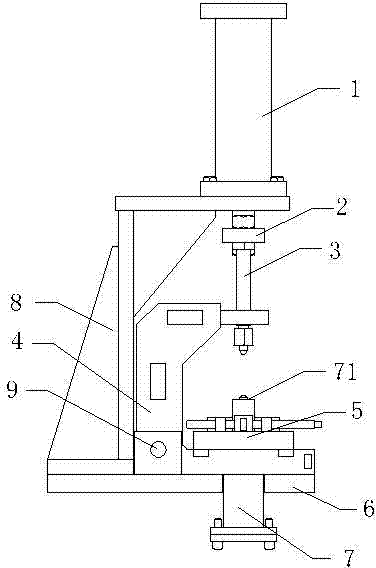

[0023] Embodiment: A kind of bushing fixture of this embodiment is as figure 1 , 2 , 3, and 4, including a fuselage 8 and a machine platform 6, the fuselage 8 is equipped with a plunger 3, a plunger fixing plate 2 for installing the plunger 3 and a cylinder 1 connected to the plunger 3, and the plunger 3 includes A pair of pressing rods 3 of equal length installed side by side, a chute is provided on the machine table 6, and two independent supporting carriages 4 corresponding to each pressing rod 3 are slidably connected to the chute, and the two supporting carriages 4 pass through The stud bolts 9 are connected, the upper end of the pressure rod 3 is installed in the pressure rod chute 21 formed on the pressure rod fixed plate 2 through the adjustment nut 10, the lower end of the pressure rod 3 is movably socketed on the upper part of the support carriage 4, and the support carriage 4 The lower part is also fixed with a product positioning device 5, and the product positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com