LED dimming drive system

A technology of dimming drive and LED light bar, applied in the field of control and LED dimming control, can solve the problems of high cost, large volume and high energy consumption, and achieve the effect of low cost and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

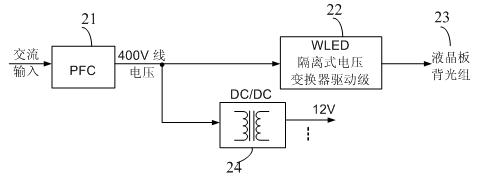

[0016] figure 2 An embodiment of the LED driving system used in the backlight field of the present invention is shown. The LED liquid crystal panel backlight group 23 adopts a two-stage drive system, including a PFC stage 21 and an isolated voltage converter drive stage 22 . The PFC stage 21 rectifies the AC power into a DC line voltage, such as rectifying the AC mains into a DC line voltage of approximately 400V. The isolated voltage converter drive stage 22 converts the line voltage into another DC voltage to provide a stable power supply for the LED backlight group 23 , which does not include a non-isolated boost converter (such as a Boost circuit). The LED liquid crystal panel backlight group 23 is one or more LED light bars. Each light bar is one or more LEDs connected in series. In addition, the drive system also includes a system power converter 24, which converts the line voltage into multiple low-value DC voltages, and provides working power for the isolated volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com