Transflective fringing field switching type liquid crystal display and manufacturing method thereof

A fringe field switching, liquid crystal display device technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of difficult processing of resin 10, expensive resin processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

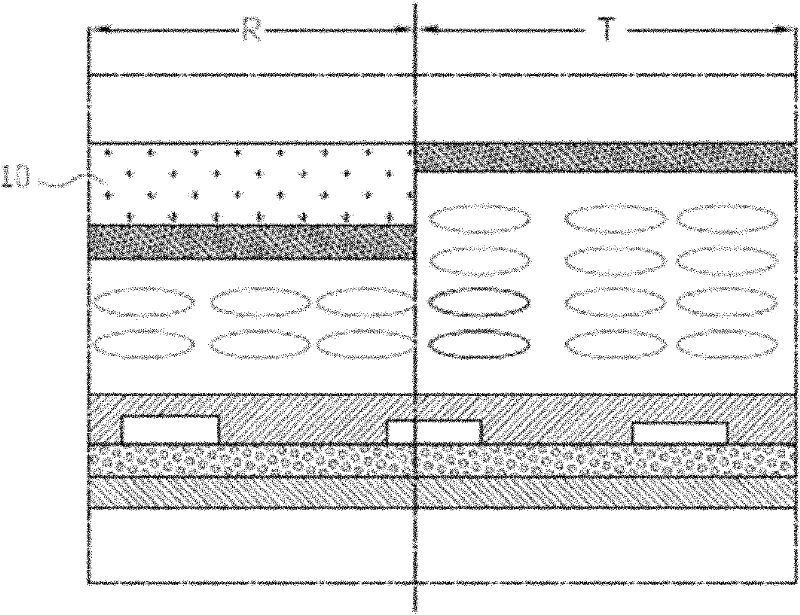

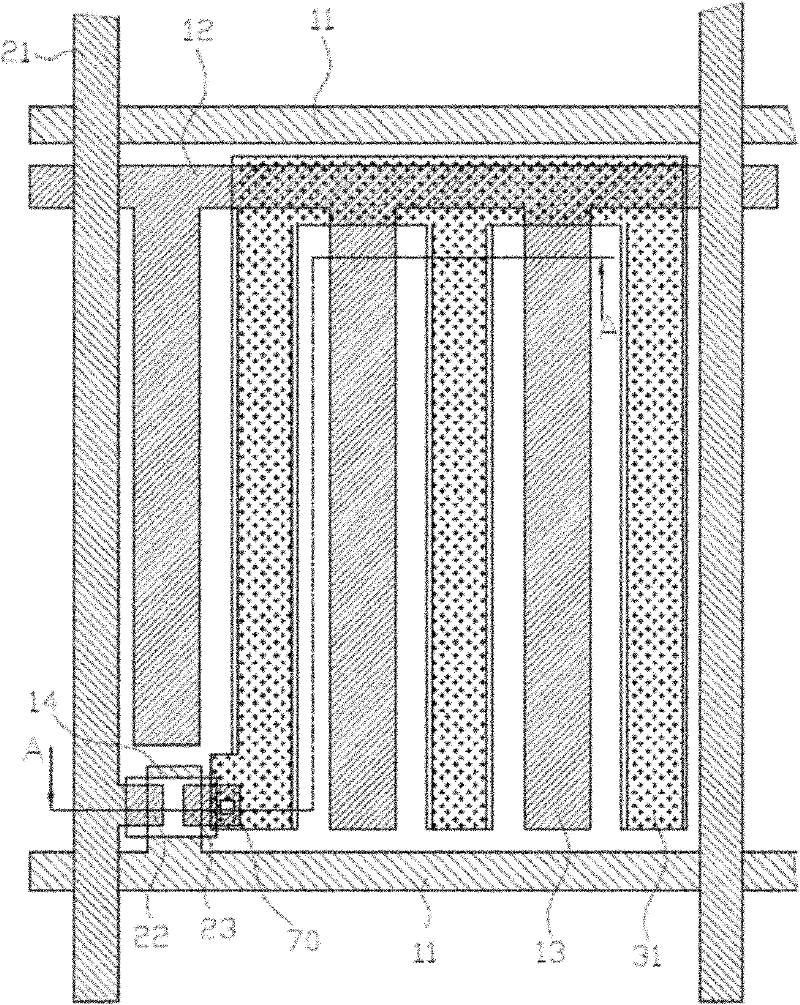

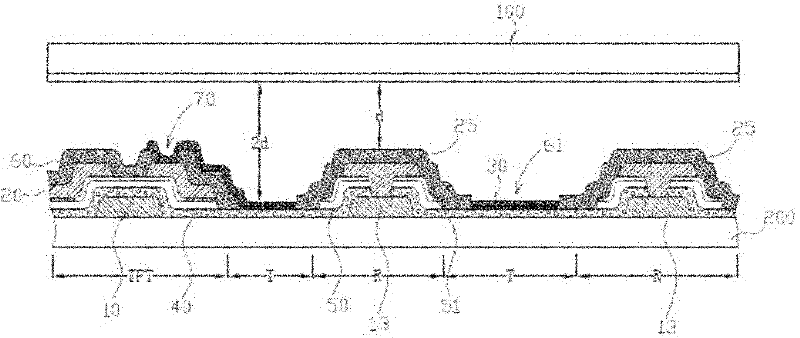

[0020] Please also refer to figure 2 with image 3 shown, where figure 2 It is a schematic diagram of the first embodiment of the FFS transflective liquid crystal display panel of the present invention, image 3 for figure 2 A cross-sectional view along the A-A direction, in the present invention, the pixel display area includes a reflective area R and a penetrating area T, such as image 3 shown, and also refer to figure 2, a first substrate 100, a second substrate 200 and the first substrate 100 are arranged oppositely, a first metal layer 10 is deposited on the second substrate 200, and the first metal layer 10 is formed with scanning lines 11 and common electrode lines 12 , common electrode 13, gate 14, wherein scanning line 11 and common electrode line 12 are arranged along the horizontal direction, common electrode 13 is arranged along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com