Miniature diaphragm valve

A diaphragm valve and valve body technology, applied in the direction of diaphragm valves, diaphragms, valve details, etc., can solve the problems of high manufacturing precision requirements, narrow application range, and difficult manufacturing process to meet the requirements, so as to reduce processing accuracy requirements and improve pressure resistance Ability, the effect of improving the performance of fluid pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

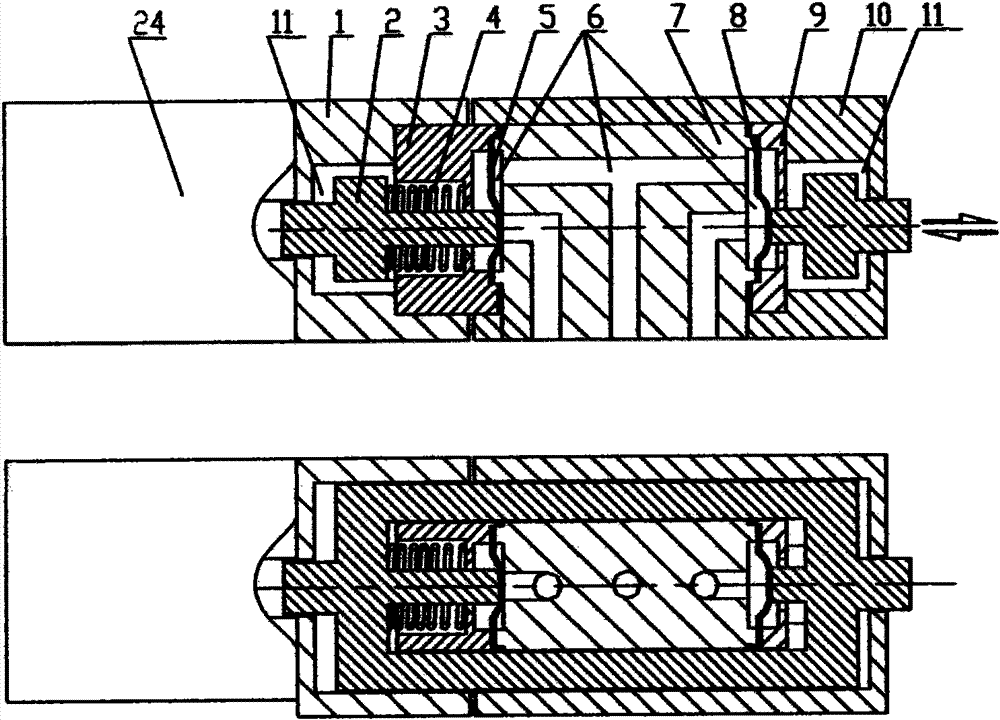

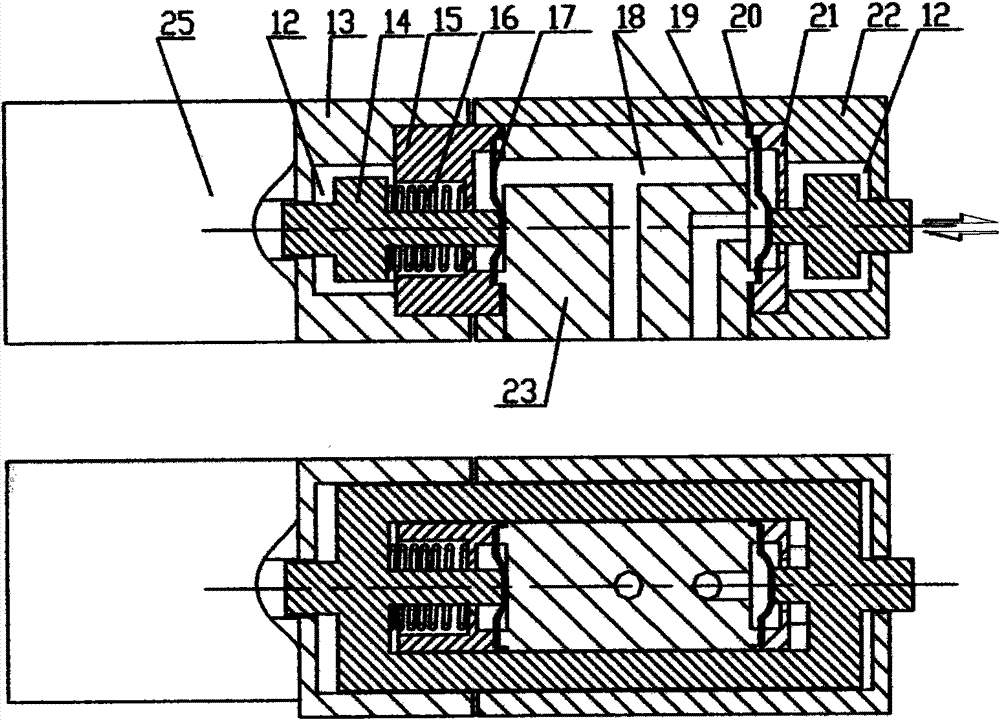

[0015] The realization example of the present invention comprises housing 1, 10, push-pull rod 2, pressure block 3, 9, spring 4, diaphragm 5, 8, valve body 7, driving device 24. Shells 1 and 10 are wrapped on the outside of valve body 7, briquetting blocks 3 and 9, and the periphery of diaphragm 5 and 8 is pressed on valve body 7 through briquetting blocks. There is a cavity 11 between them, and the push-pull rod 2 is located in the cavity 11; the push-pull rod 2 can move back and forth within a certain range in the cavity 11, and the diaphragm 5, 8 and the valve body 7 form an inner cavity 6; the diaphragm 5 , 8 is soft and flexible, and the inner cavity is connected to the outside with three channels, wherein the openings of the first and second channels in the inner body of the cavity 6 are surrounded by valve seats and correspond to the diaphragms 5 and 8 respectively; When there is fluid pressure in the cavity 6, the diaphragms 5 and 8 are under pressure, and some of them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com