Forced lubricating device for through type vehicle interaxle differential

An inter-axle differential and through-type technology, which is applied in the direction of differential transmission, transmission, gear lubrication/cooling, etc., can solve the problem of increasing maintenance and production costs, reducing the utilization rate of heavy trucks, and insufficient gears Lubrication and other problems to achieve the effect of reducing wear and burnout, reasonable structure, and reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

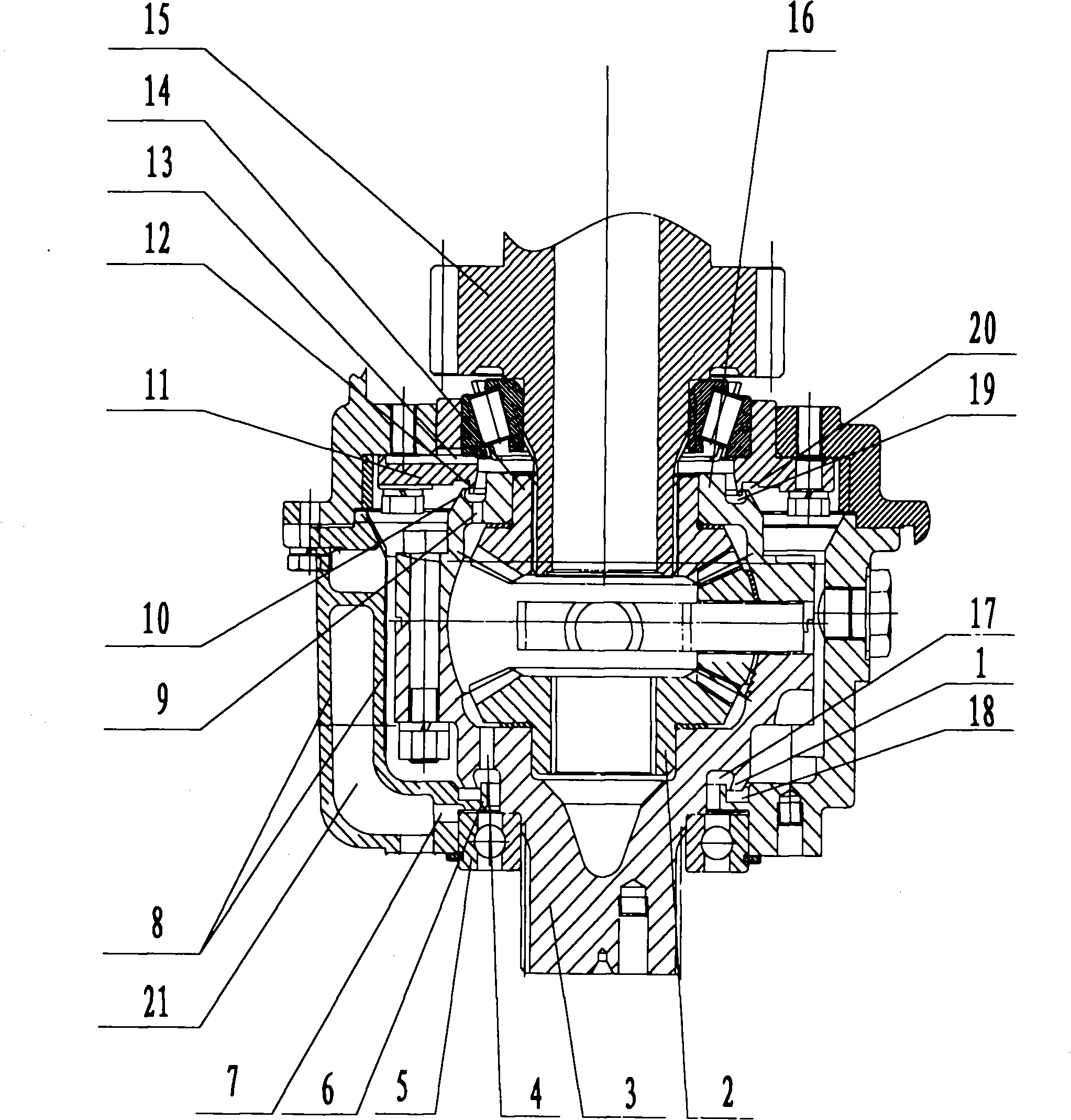

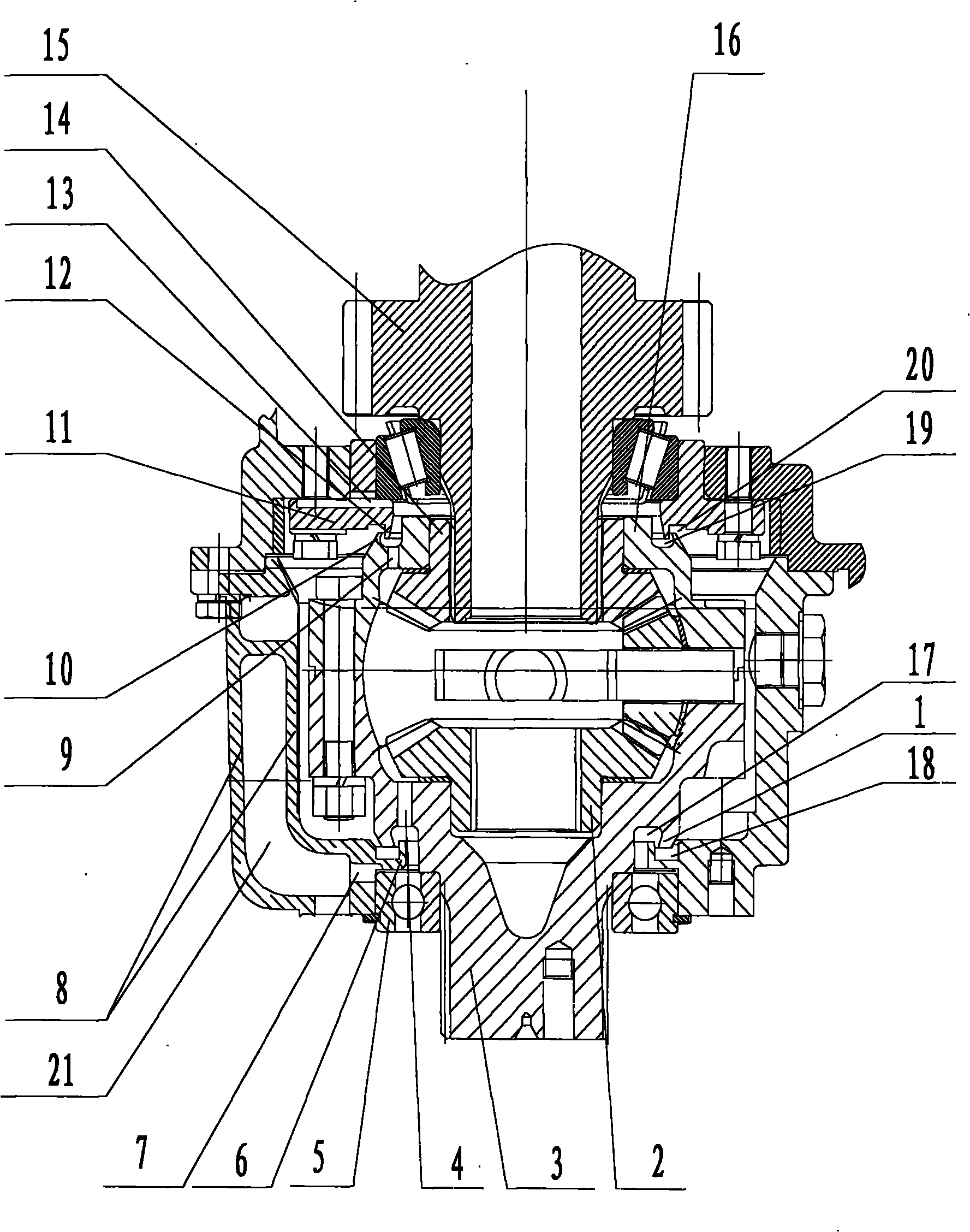

[0010] From figure 1 , as can be seen in Fig. 2: a kind of forced lubricating device of automobile through-type inter-axle differential, including inter-axle differential front case 3, inter-axle differential rear case 16, inter-axle differential case 8, Bearing housing 11, roller bearing 5, front half shaft gear 2, rear half shaft gear 14, planetary gear, cross shaft and output cylindrical gear 15, bolts for inter-axle differential front case 3 and inter-axle differential rear case 16 Connected to form the inter-axle differential housing, the front and rear side gears 2, 14, planetary gears and cross shafts are all installed in the inner cavity of the inter-axle differential housing. The inter-axle differential housing is installed in the inter-axle differential housing 8 with roller bearings 5, and the output cylindrical gear 15 is installed on the bearing seat 11 with tapered roller bearings, and the bearing seat 11 is installed on the inter-axle differential case. On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com