Air type position compensation device

A compensation device and air-type technology, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as hidden dangers in use, front and rear pressure differences affecting service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

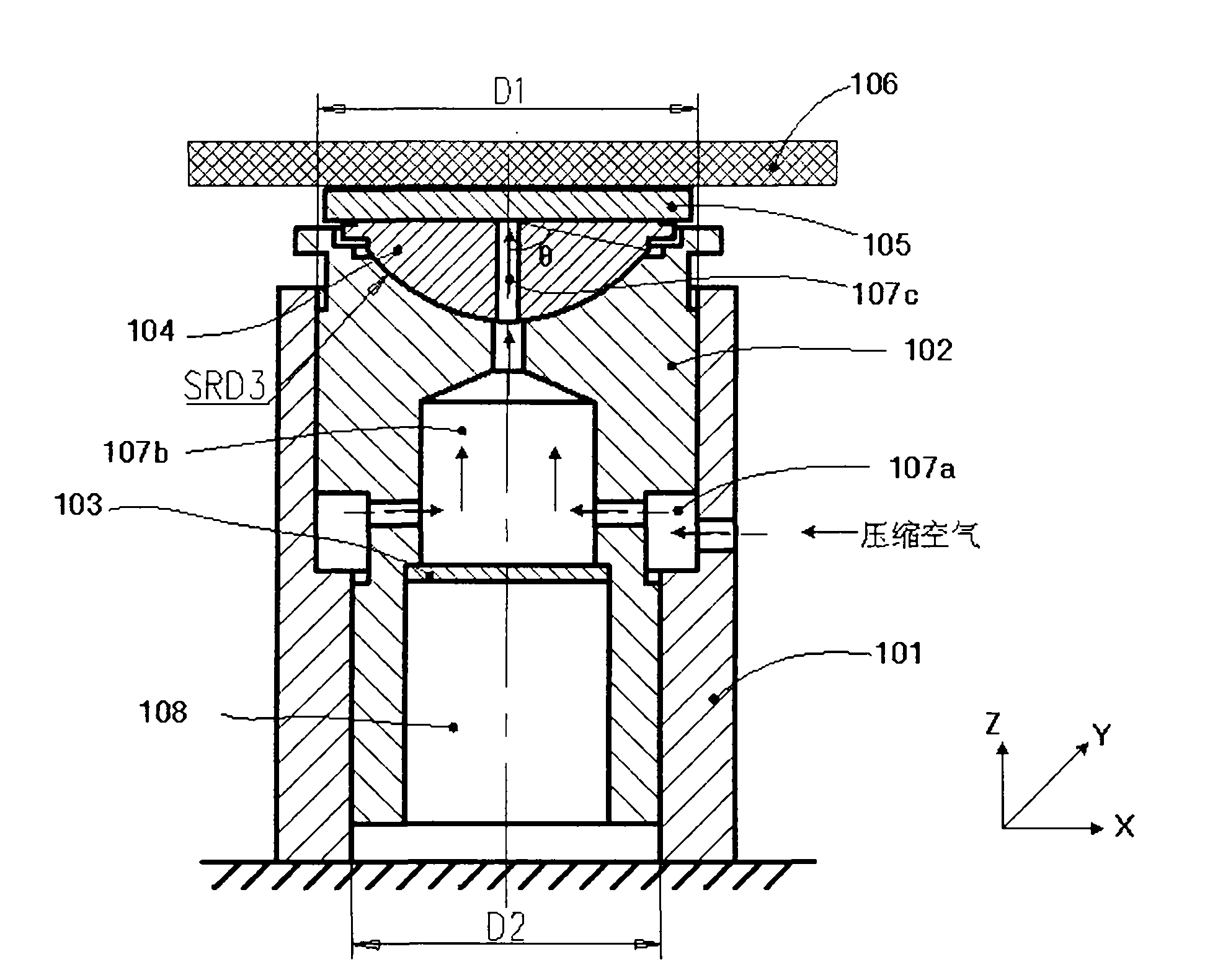

[0020] figure 1 Structural diagram of the air type position compensation device provided by the present invention.

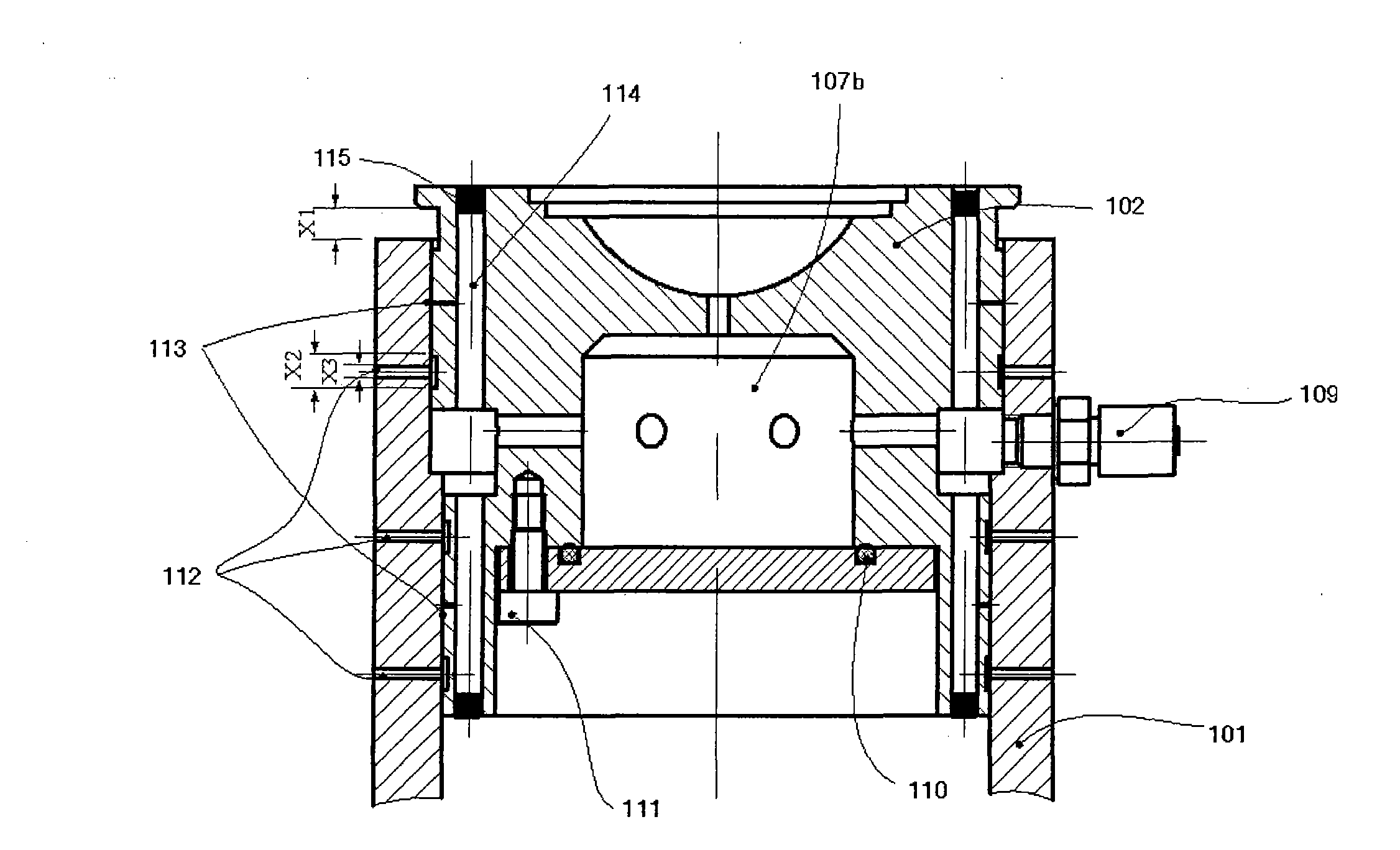

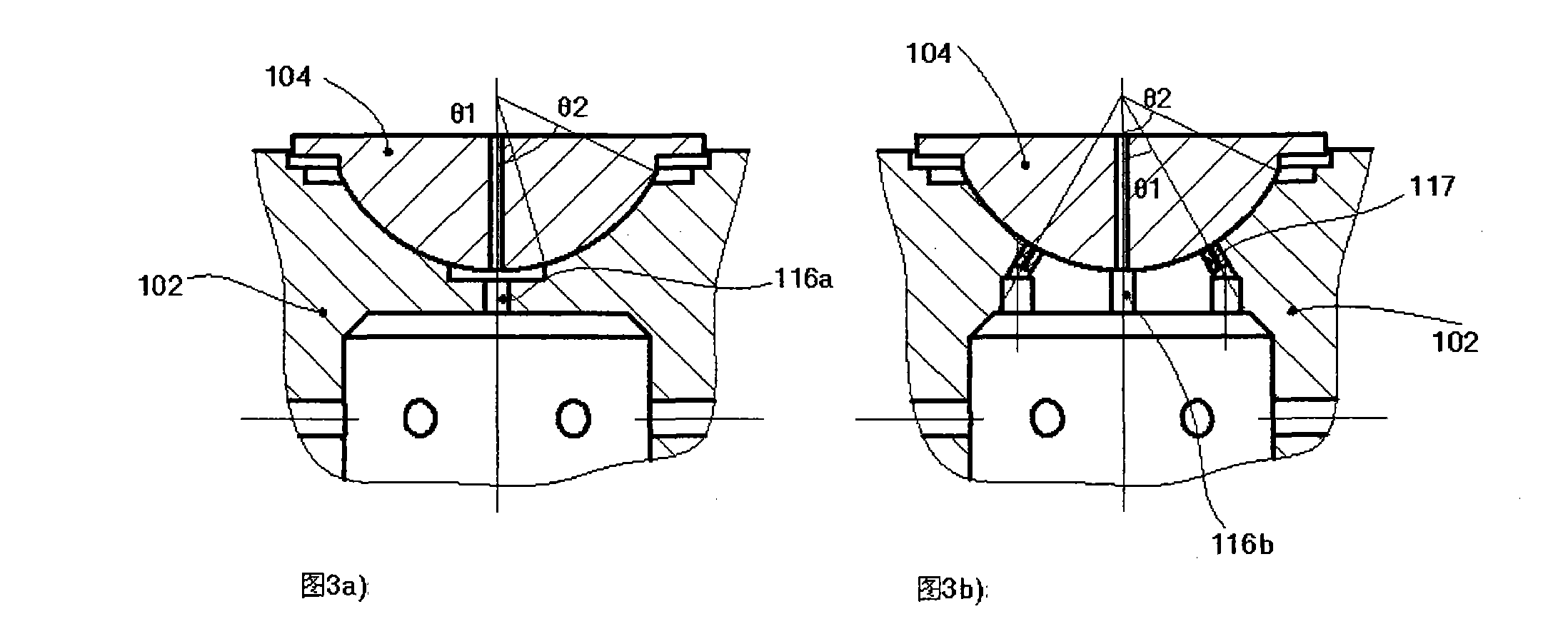

[0021] Such as figure 1 As shown, the air type position compensation device provided by the present invention includes: a base 101 , a variable-section piston 102 , an air chamber seal 103 , a spherical air bearing 104 , a horizontal air bearing 105 and a driving object 106 . Wherein, the variable cross-section piston 102 is located in the base 101 and can move vertically (Z direction). The side wall depression in the middle position between the base 101 and the variable cross-section piston 102 forms a first air chamber 107a, and the inside of the variable cross-section piston 102 There is a second air cavity 107b at the middle and upper end, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com