Method and tooling for installing camshafts

An installation method and camshaft technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., to achieve the effect of reasonable method steps, convenient and quick assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

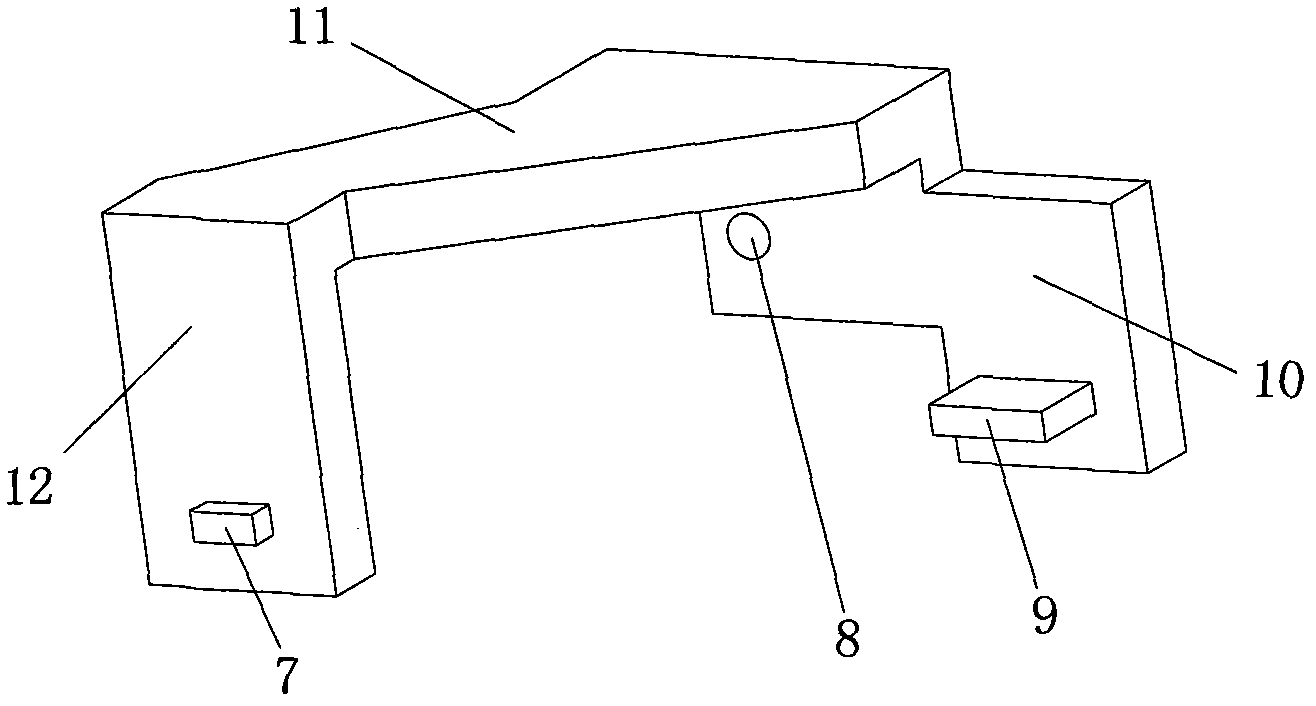

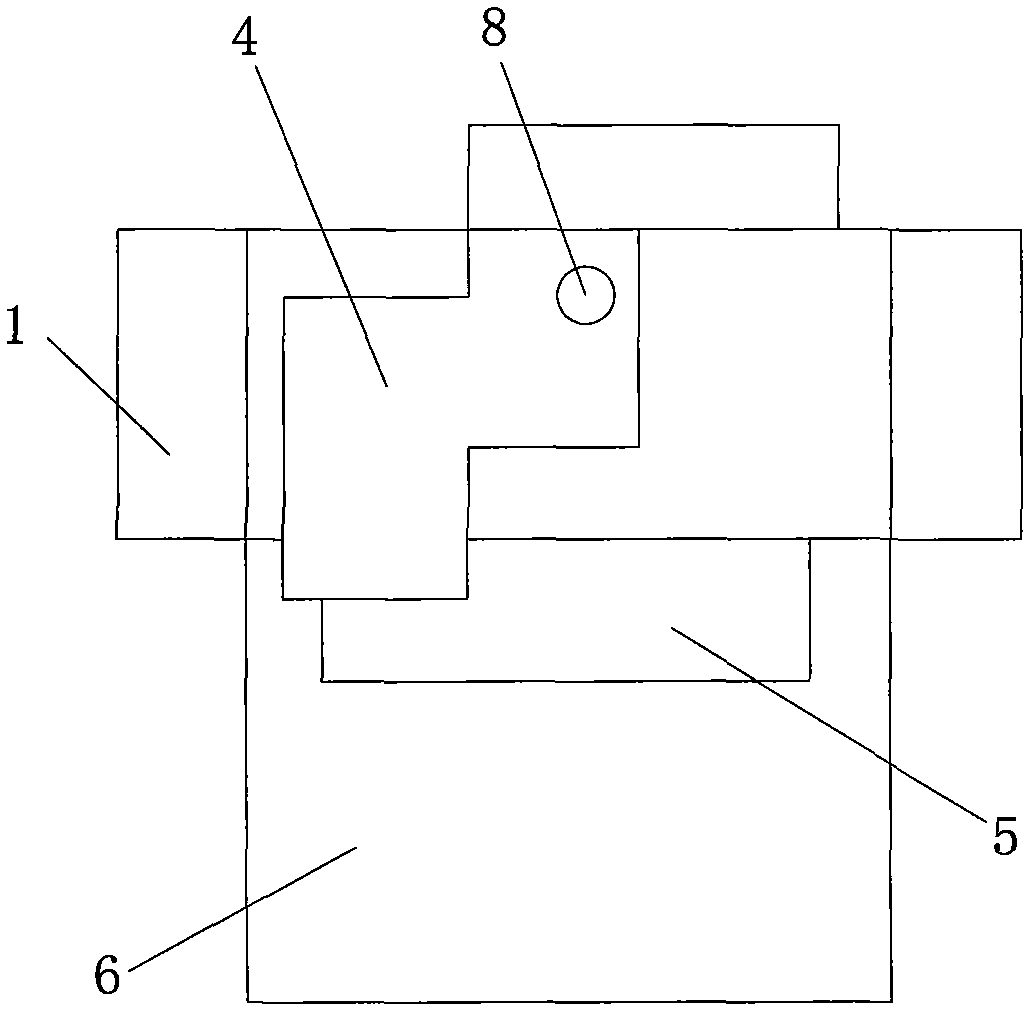

[0021] Example 1, such as figure 1 As shown, a camshaft installation tool can be divided into three parts as a whole, which includes a front arm 12, a rear arm 10, and a connecting arm 11. The front arm 12 is provided with a first protruding key 7 that matches the groove on the rear end of the exhaust camshaft 2; the rear arm 10 is provided with a groove that matches the rear end of the intake camshaft 3 The second protruding key 9 and the bolt holes 8 for fixing the installation tool on the frame 1 are provided.

Embodiment 2

[0022] Embodiment 2, a camshaft installation tool, in order to adapt to the frame 1, the connecting arm 11 is adapted to the upper top surface of the frame, and the rear arm 10 is adapted to the rear end surface of the frame 1 . All the other are with embodiment 1.

Embodiment 3

[0023] Embodiment 3, a camshaft installation tool, the shape of the first protruding key 7 and the second protruding key 9 is a cuboid. The forearm 12 and the rear arm 10 are parallel to each other. All the other are with embodiment 1 or 2.

[0024] In order to make its manufacturing process simple and low in cost, the tooling material is steel plate.

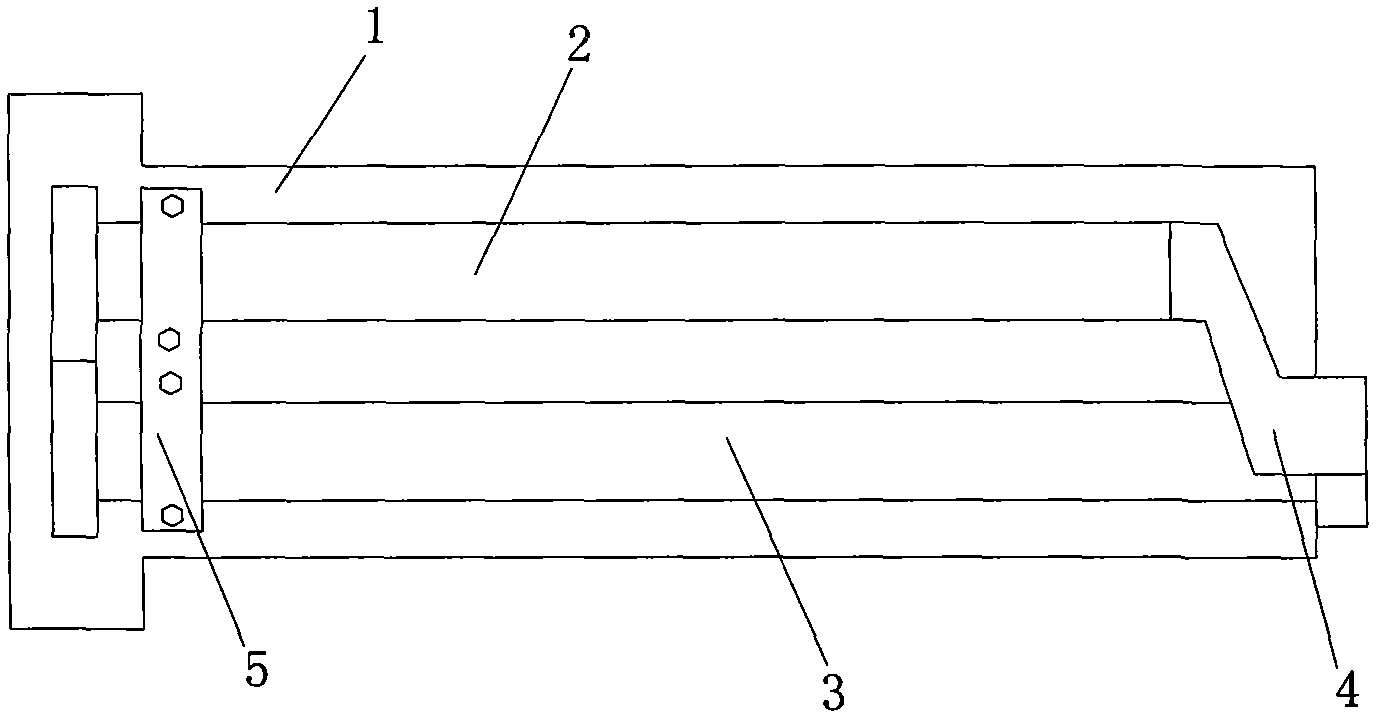

[0025] The exhaust camshaft and the intake camshaft are fixed through the cylinder head, the camshaft frame and a separate camshaft bearing cap. During the assembly process, the camshaft installation tool 4 needs to be used to sub-assemble the camshaft, and then the camshaft The shaft fits correctly on the cylinder head.

[0026] In the present invention, the using method of camshaft installation tool comprises the following steps:

[0027] First, put the camshaft frame 1 upside down on the workbench, place the cleaned intake camshaft and exhaust camshaft on the camshaft frame, and turn the intake camshaft and exhaust camsha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com