Permanent-magnet multiplied-pole switch reluctance motor

A switched reluctance and motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of small magnetic energy area, material waste, and little progress in switched reluctance motors, and achieve the effect of power improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

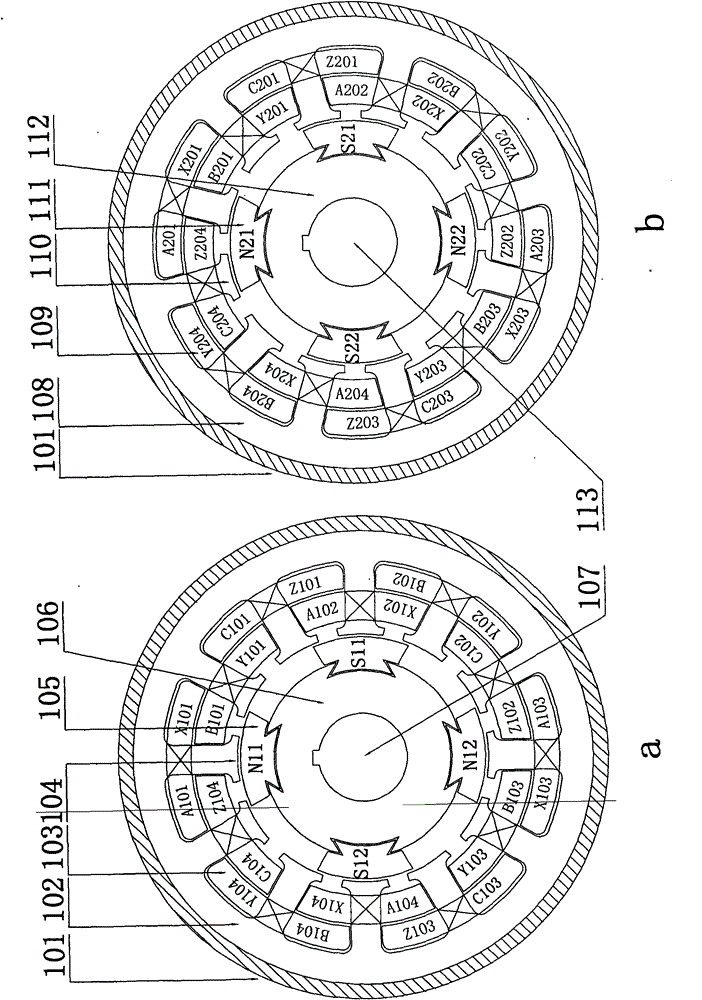

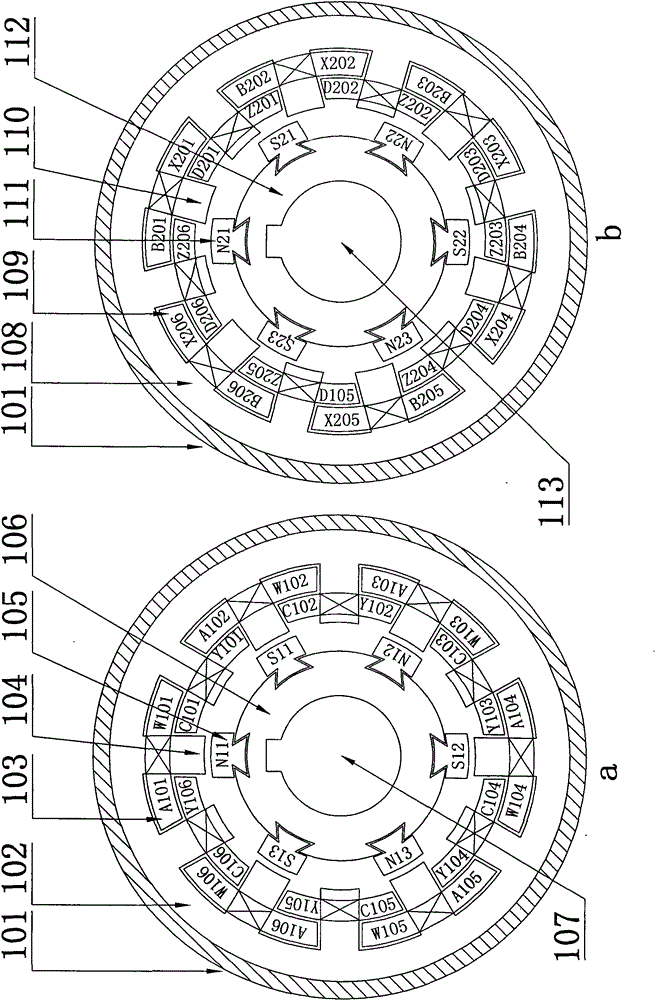

[0047] A permanent magnet multi-pole switched reluctance motor includes a motor casing 101 placed on a motor foot 132 through a motor foot fixing screw hole 131, a motor shaft extension end 118, a motor non-shaft extension end 129, and a built-in motor casing 101. Stator and rotor with doubly salient structure made of laminated silicon steel sheets (see Figure 7 ~ Figure 10 ). The middle part of the motor casing 101 is provided with a motor suspension ring 123; the two ends of the motor shaft extension end 118 are respectively provided with a front end cover 120 and a rear end cover 125, and the front end cover 120 and the rear end cover 125 are connected to the motor casing 101 through a fixing screw 121; The end cover 125 is equipped with a windshield 130, and the windshield 130 is provided with a motor fan 127; a sensor 128 is arranged between the motor fan 127 and the rear end cover 125; the front end cover 120 and the rear end cover 125 pass through the front bearing 119...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com