Polymer dispersed liquid crystal three steady-state membrane and preparation method thereof

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as the inability to function as a switchable energy-saving window, and achieve the effect of increasing infrared light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

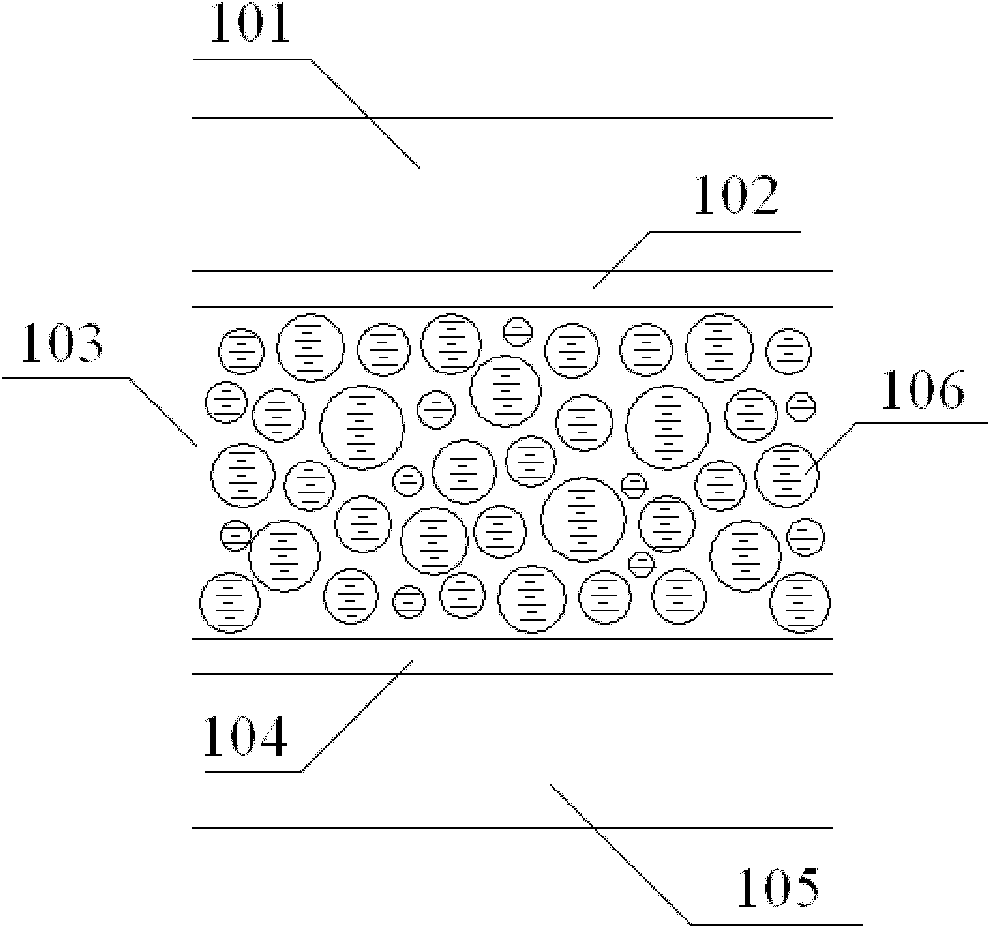

[0032] A polymer dispersed liquid crystal tristable film, such as figure 1As shown, it includes two layers of flexible transparent conductive films 101, 105 and a polymer dispersed liquid crystal layer 103 arranged between the two layers of flexible transparent conductive films 101, 105, and the inner surface of the flexible transparent conductive film 101 is provided with a transparent conductive film Layer electrode 102, the inner surface of flexible transparent conductive film 105 is provided with transparent conductive thin-layer electrode 104, the thickness of polymer dispersed liquid crystal layer 103 is 30 μ m, the average diameter of the liquid crystal droplet 106 in polymer dispersed liquid crystal layer 103 is 3 ~5 μm; the polymer-dispersed liquid crystal layer 103 is mainly made of a prepolymer, a chiral dual-frequency liquid crystal material and a pad material, which are fully stirred and uniformly mixed, and the weight ratio of the prepolymer and the chiral dual-f...

Embodiment 2

[0039] The polymer-dispersed liquid crystal tristable film described in Preparation Example 1 is carried out in an ultra-clean workshop, and the preparation method mainly includes the following steps:

[0040] ①Weigh the prepolymer and chiral dual-frequency liquid crystal material according to the weight ratio of 1: (1~3), and weigh them at 1~10 pieces / mm 2 Add the content of the liner material, and fully stir and evenly mix the prepolymer, chiral dual-frequency liquid crystal material and liner material at room temperature; here, the prepolymer, chiral dual-frequency liquid crystal material and liner material can specifically be Match according to the actual situation.

[0041] The prepolymer is mainly composed of polymerizable monomers, chain transfer agents and photoinitiators. The weight percentage of each component is: 20% of polymerizable monomer propoxynonyl phenyl acrylate, 20% of polymerizable monomer trimethylol Propane triacrylate was 70%, chain transfer agent seba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com