Screw compressor

A screw compressor and compressor rotor technology, applied in mechanical equipment, machines/engines, rotary piston machinery, etc., can solve the problems of unreliable operation of screw compressors and body friction, etc., to eliminate abnormal noise and improve operation reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

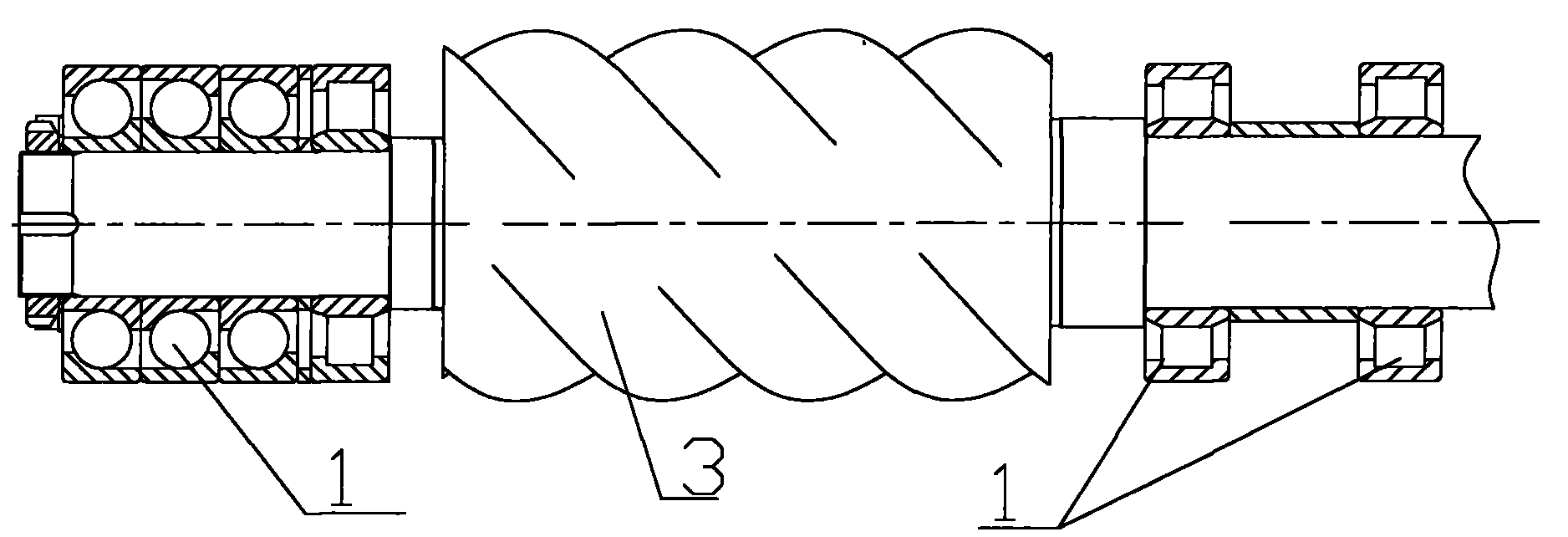

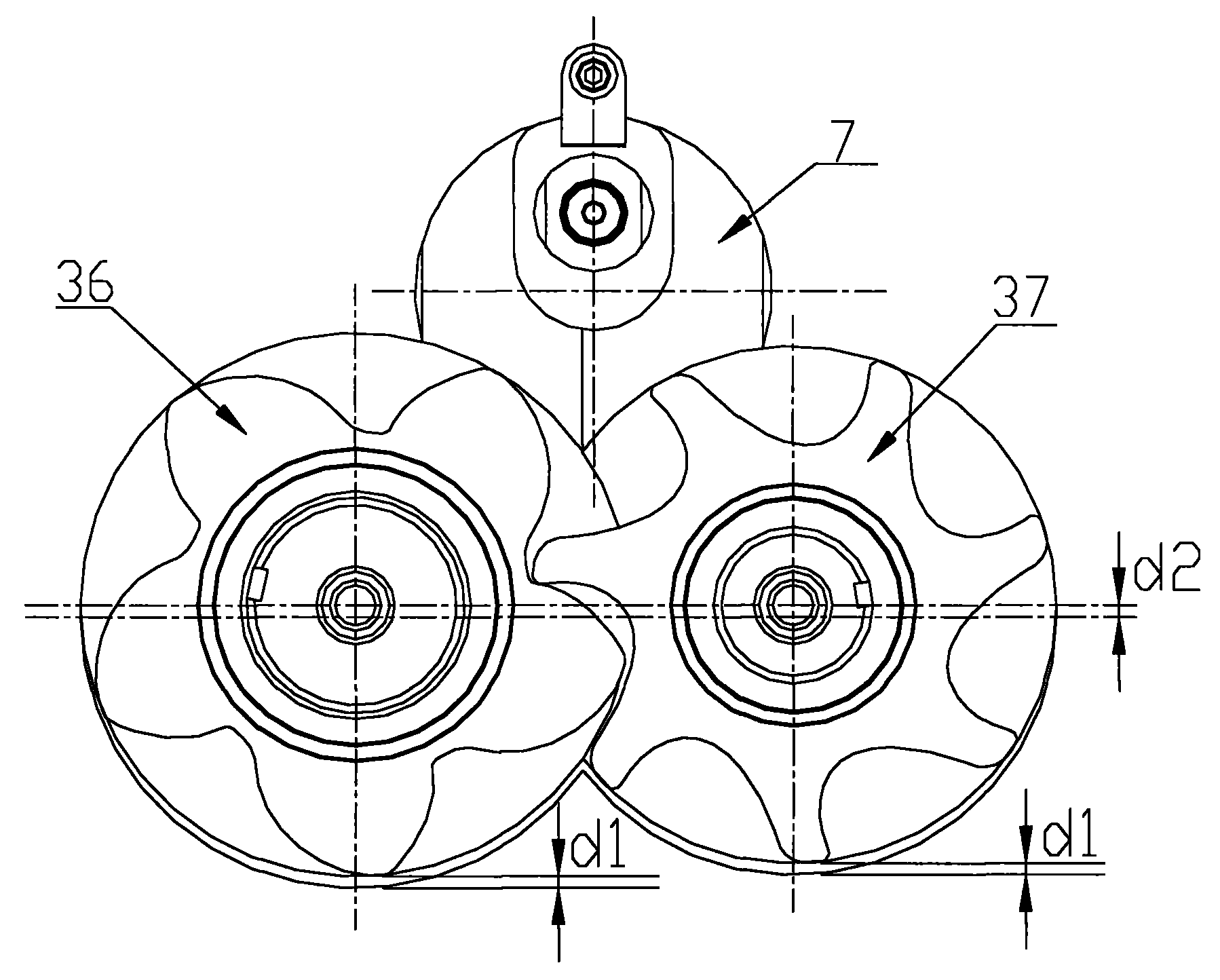

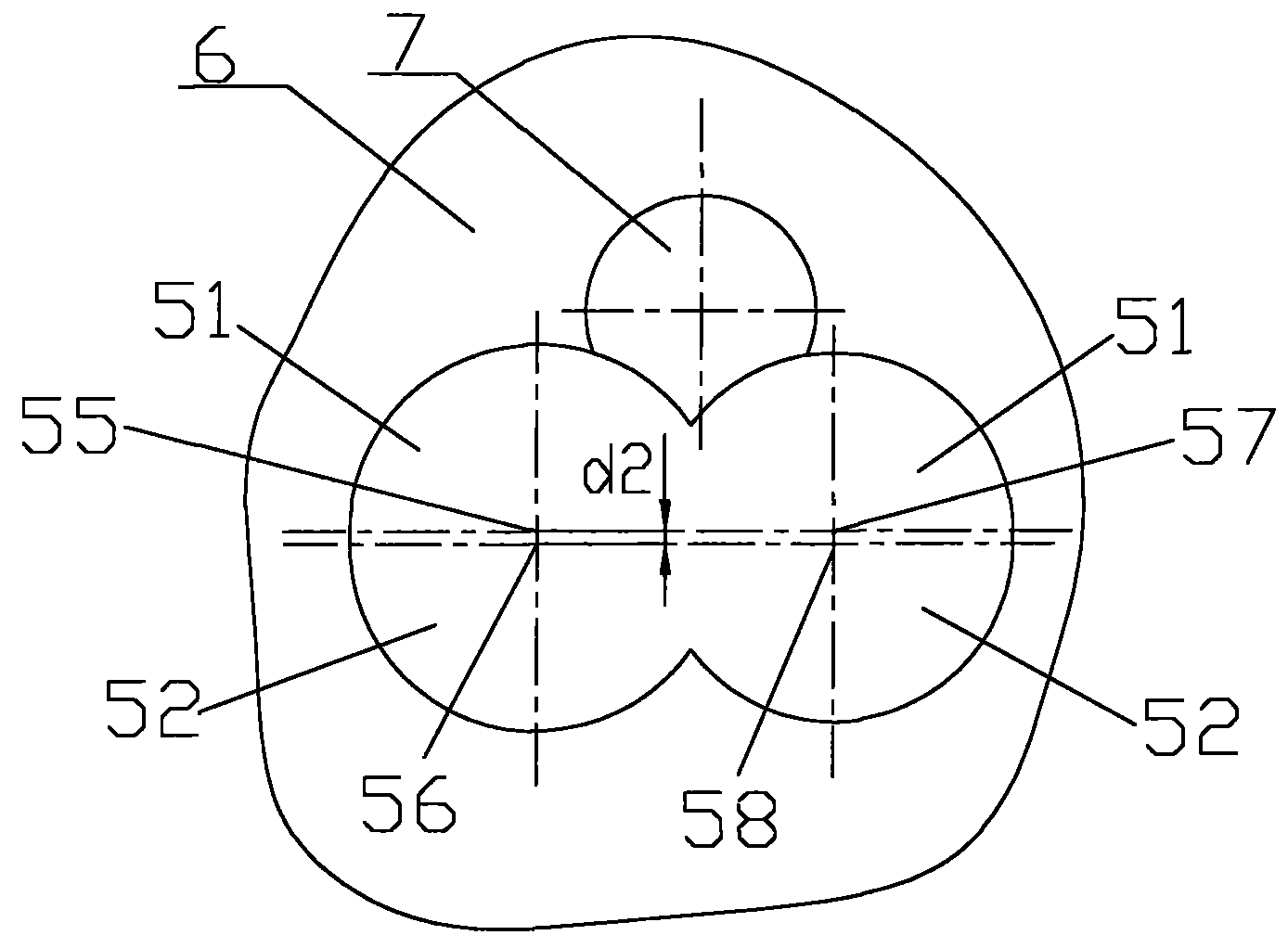

[0018] Figure 1 to Figure 3 Schematically shows the structure of a screw compressor according to an embodiment of the present invention, as shown in the figure, including: a machine body 6; The shaft center of 36 and the shaft center of the female rotor 37 are located on the same horizontal plane; bearing 1; slide valve; body 6 has a slide valve chamber 7 for accommodating the slide valve and a compression chamber for accommodating the compressor rotor 3; the compressor rotor 3 is supported by the bearing Part 1 is supported in the compression chamber; the distance d1 from the lowermost end of the circumscribed circle of the compressor rotor 3 to the lowermost end of the compression chamber is greater than the distance from the uppermost end of the compressor rotor's circumscribed circle to the uppermost end of the compression chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com