Low-rise mixed lightweight steel structured building

A light steel structure and building technology, applied in the direction of building structure, building, building components, etc., to achieve the effect of short construction period, excellent physical properties, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (body of walls).

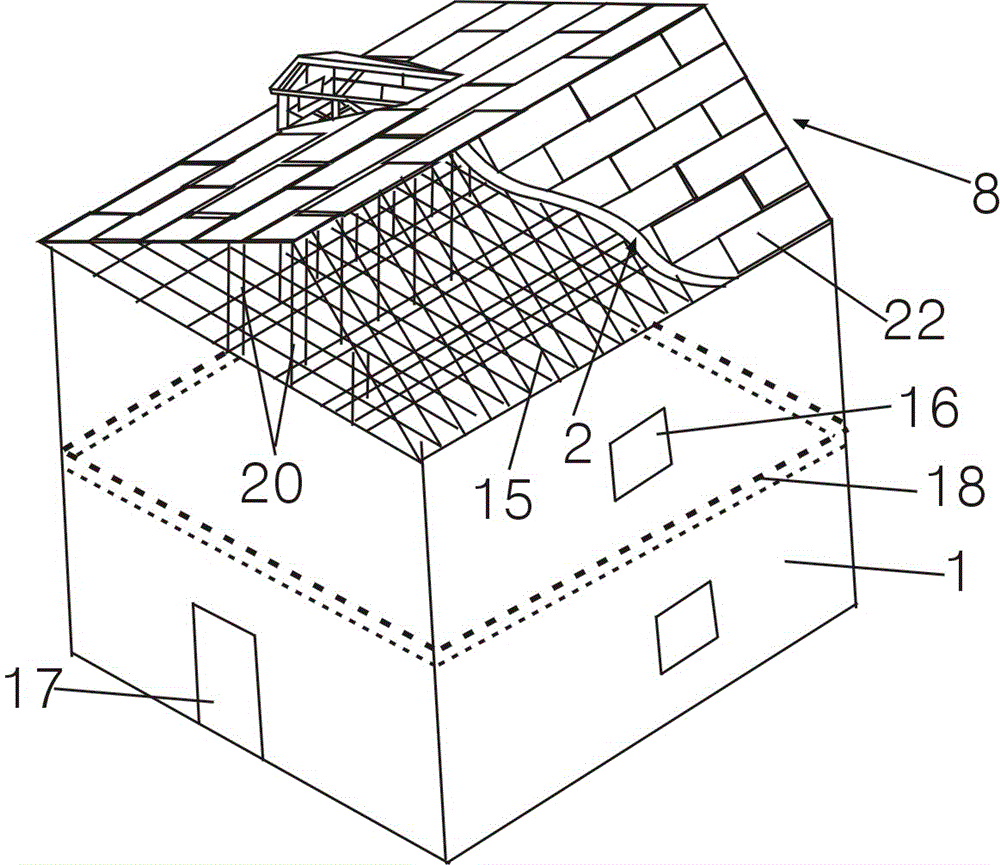

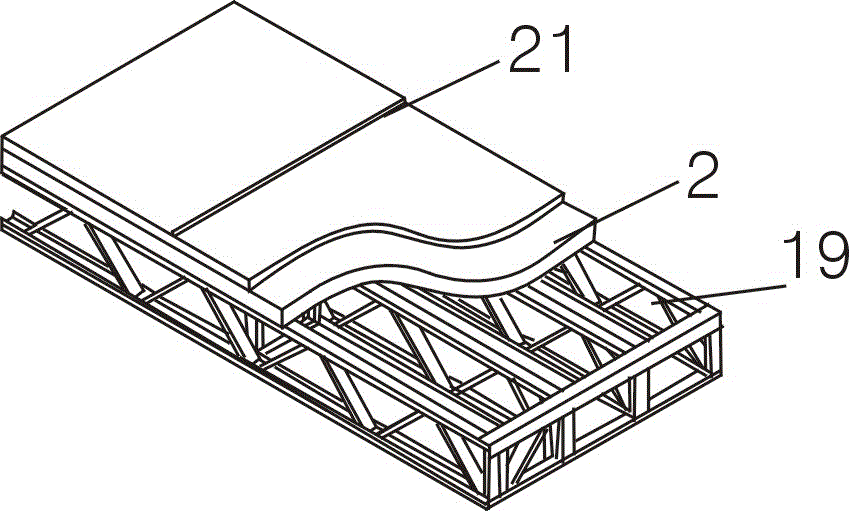

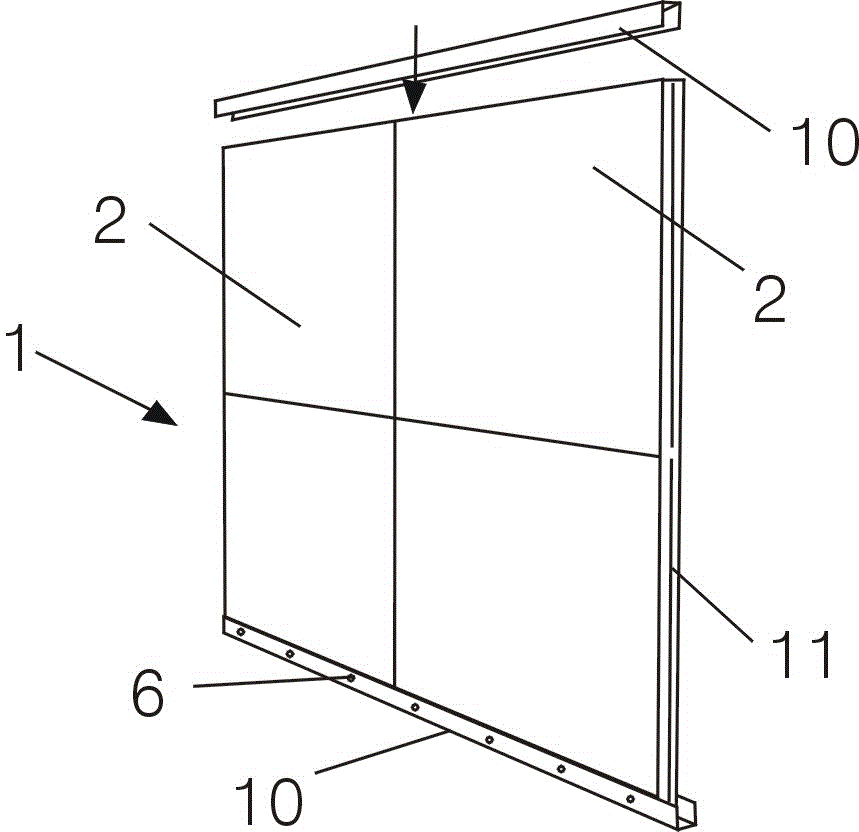

[0037] See Figure 3-9 , the steel structure wall of this embodiment, including the polyurethane composite board 2, is spliced into a wall body 1 by several polyurethane composite boards 2, see image 3 .

[0038] See Figure 4 , 5. The polyurethane composite board 2 has a three-layer structure, the two outer layers are non-combustible panels 3, and the middle layer is polyurethane 4. The non-combustible panel 3 is calcium silicate board or magnesium oxide board, and the polyurethane 4 is flame-retardant or flame-retardant polyurethane. Grooves 11 are set in the four sides of the polyurethane composite board 2 in this embodiment, the grooves are butted between the two polyurethane composite boards 2, and the square light steel 9 is inserted in the groove 11 of the two polyurethane composite boards 2, inside the square light steel 9 Air filled polyurethane4. Figure 5 The groove 11 of two polyurethane composite boards is inserted in...

Embodiment 2

[0043]Embodiment 2 (body of walls).

[0044] See Figure 10-12 The difference between this embodiment and Embodiment 1 is that the upper and lower ends of the wall 1 are embedded in the wall 1 by the first concave light steel 10 through the slot 7 .

Embodiment 3

[0045] Embodiment 3 (inner wall).

[0046] See Figure 13-14 In this embodiment, the polyurethane composite board 2 is a square with four sides, and the four sides are grooves 11. The polyurethane composite boards 2 are spliced by a connector 13 and fixed in the frame 5 by the fastener 6 to form a wall 1. Connectors can be square light steel or wood. This method is suitable for interior wall compartments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com