Foam concrete material, foam concrete and preparation method thereof

A foam concrete and foaming technology, which is applied in the field of foam concrete and its preparation, and foam concrete materials, can solve the problems of wasting waste cement mortar and pollution, and achieve the effects of environmental protection, cost reduction, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

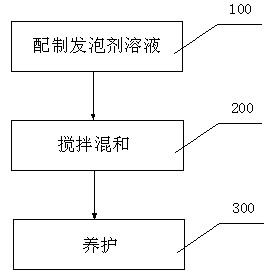

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0021] The specific implementation mode of the present invention is: provide a kind of foam concrete material, comprise solid component and blowing agent foam, described solid component is: waste cement mortar dosage 50-70 parts, cement dosage 15 parts-30 parts, 0.3 parts-0.6 parts of wood glue powder, 5 parts-20 parts of gypsum, 10 parts-30 parts of slaked lime, the volume of the foam of the foaming agent is 40-40 parts of the total volume of the solid components 80 times, the foaming agent foam is obtained by foaming an aqueous foaming agent solution with a mass ratio of foaming agent to water of 1:20 to 1:40. The radial length of the solid particles is less than 1 mm, preferably less than 0.5 mm. The waste cement mortar is waste cement mortar in the process of concrete production. The foaming agent adopts vegetable protein foaming agent.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com