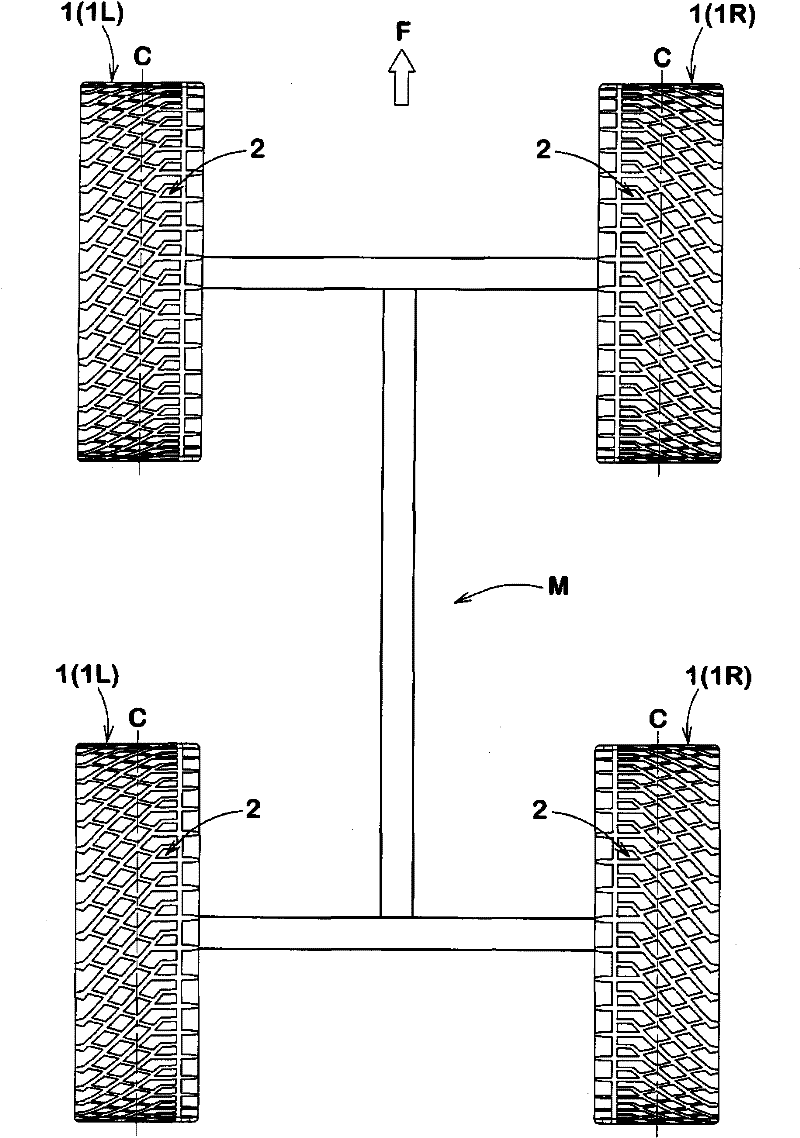

Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve high lateral grip and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

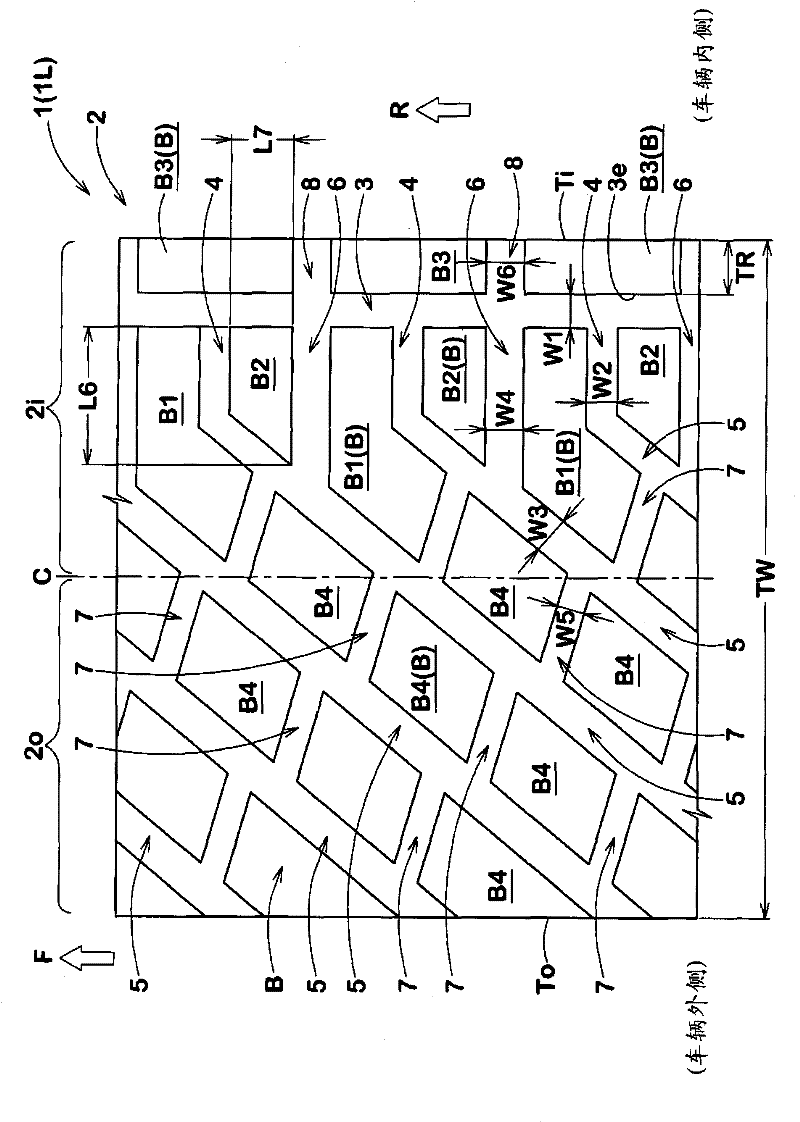

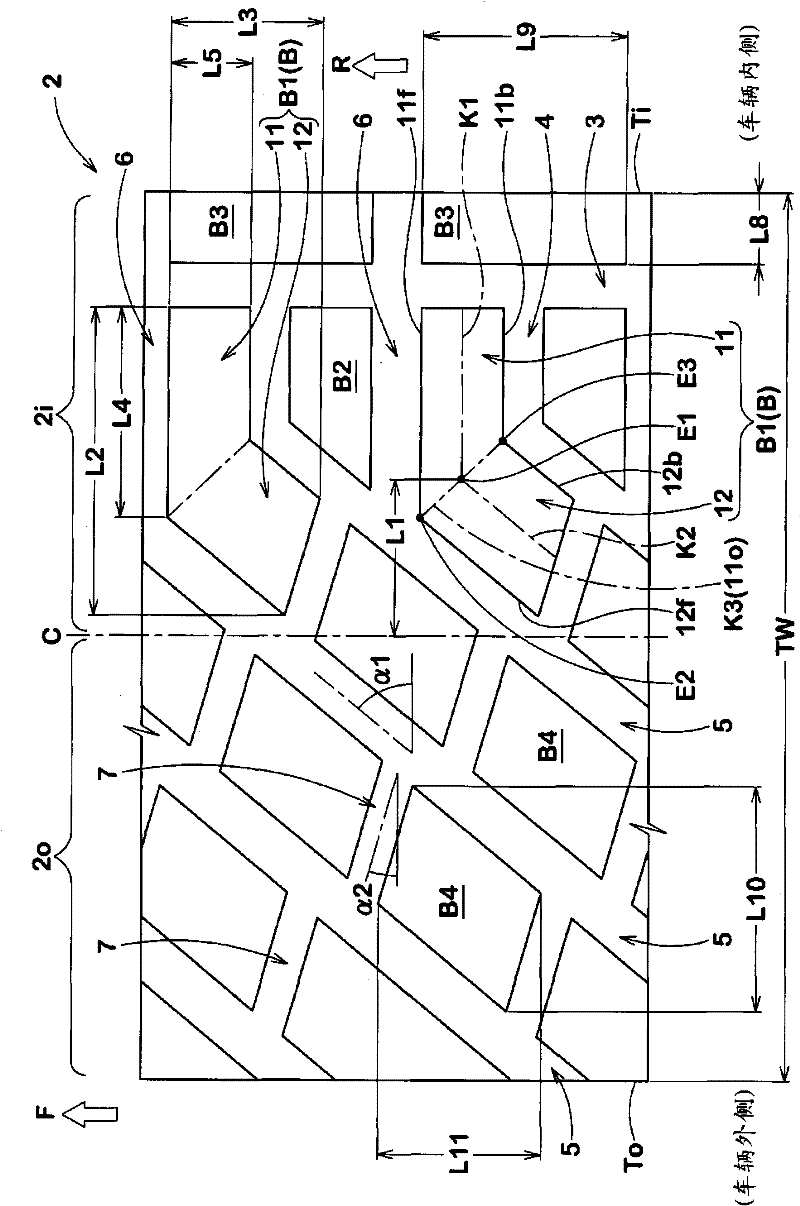

[0074] Pneumatic tires having tread portions having the specifications shown in Table 1 were tested, and their performances were compared. Also, for comparison purposes without having Figure 7 The tread portion of the curved block shown, and having the Figure 8 The same test was carried out on the pneumatic tire in which the shown substantially U-shaped blocks were arranged on the tread portion near the tire equator.

[0075] Tire size: 205 / 60R15

[0076] Rim size: 7J×15

[0077] Tread contact width TW: 190mm

[0078] Inner circumferential groove (groove width W1, groove depth) = (9.0mm, 11.5mm)

[0079] The first transverse groove (groove width W2, groove depth) = (8.0mm, 11.5mm)

[0080] Inclined groove (groove width W3, groove depth) = (10.0mm, 11.5mm)

[0081] Second transverse groove (groove width W4, groove depth) = (10.0mm, 11.5mm)

[0082] Connecting groove (groove width W5, groove depth) = (7.3mm, 11.5mm)

[0083] Inner transverse groove (groove width W6, gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com