Hoisting structure of steel ladle

A technology for lifting structure and ladle, which is applied to casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of difficulty in lifting the ladle and difficult to observe, and achieve the effect of facilitating lifting and transportation and improving production efficiency.

Inactive Publication Date: 2011-05-11

WUXI JULI HEAVY IND OFF

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the above problems, the present invention provides a ladle lifting structure, which can solve the problem of difficulty in lifting the ladle caused by the fact that the driving operator is difficult to observe the lifting point of the ladle trunnion when the ladle is located in the VOD furnace or pit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

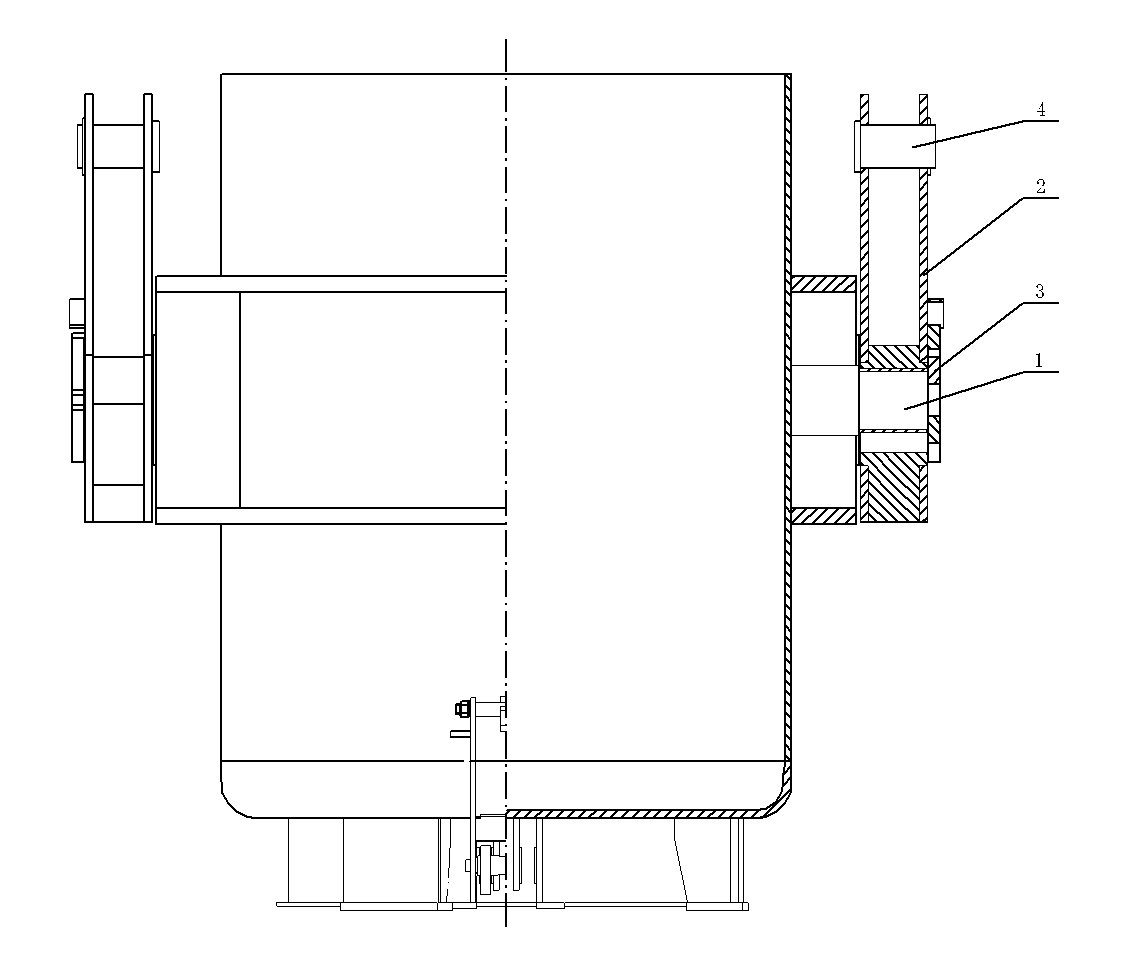

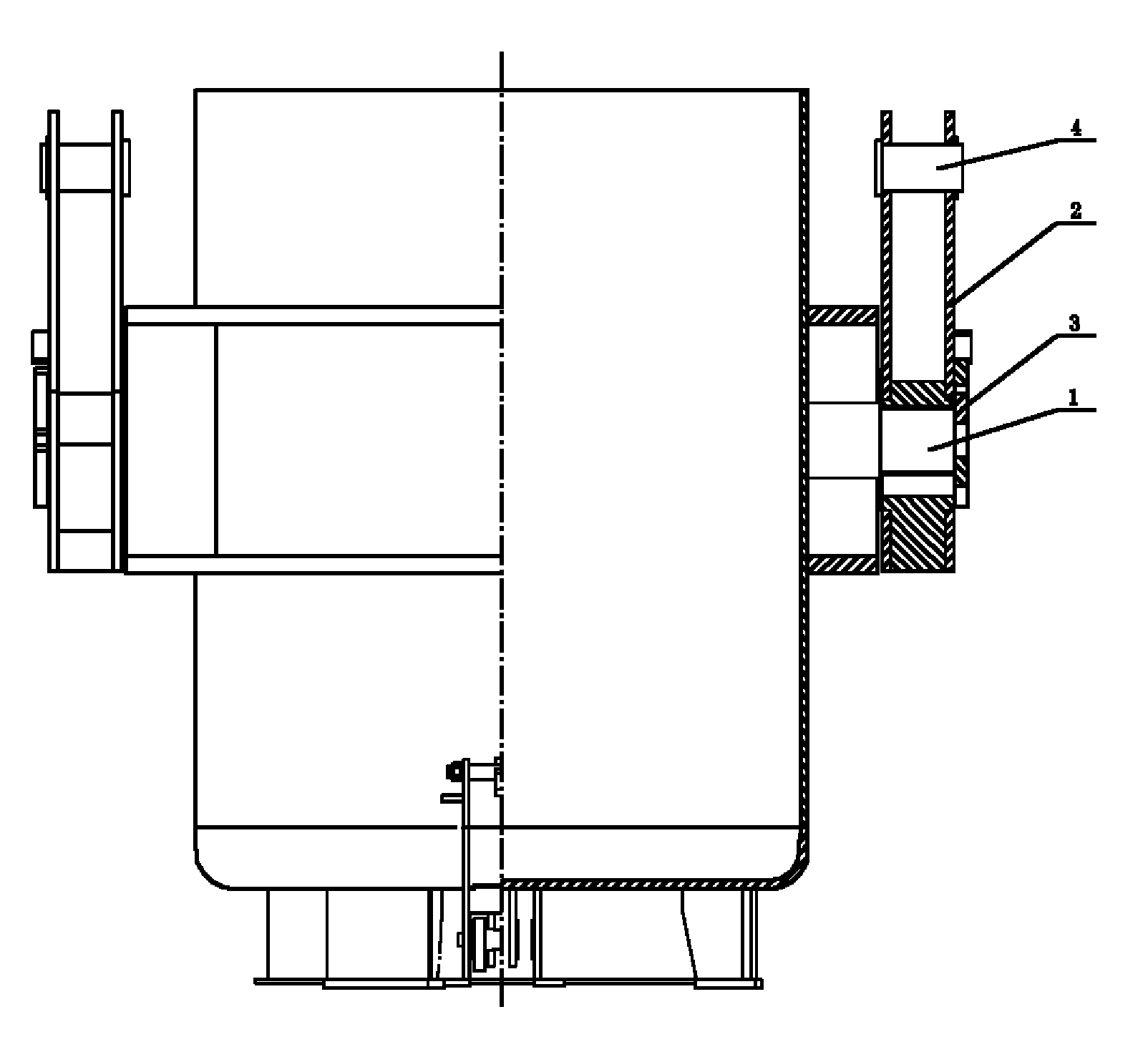

[0008] See figure 1 , the present invention includes trunnions 1 on both sides of the ladle, and the trunnions 1 on both sides of the ladle are equipped with lifting structures. The lifting structure includes a boom bracket 2, the boom bracket 2 is fixed upwardly on the trunnion 1 through a flange 3, and a suspension shaft 4 is installed on the upper end of the boom bracket 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a hoisting structure of a steel ladle, which can solve the problem that when the steel ladle is positioned in a VOD (vacuum oxygen decrease) furnace or a pit, a crane operator is hard to observe hoisting points of trunnions of the steel ladle to cause that the steel ladle is hard to hoist. The hoisting structure of the steel ladle comprises two lateral trunnions of the steel ladle and is characterized in that hoisting structures are formed on the two lateral trunnions of the steel ladle.

Description

technical field [0001] The invention relates to the technical field of metallurgical equipment, in particular to a ladle lifting structure. Background technique [0002] Generally, the steel ladle is transported for a short distance in the workshop by driving. When lifting, the driving hook hooks the two trunnions of the ladle for lifting and transportation. However, when the steel ladle is placed in the VOD furnace or pit, since the trunnion is located in the VOD furnace or In the pit, the position is low, and it is difficult for the operator to observe the lifting point of the ladle trunnion, which makes it difficult to lift the ladle. Contents of the invention [0003] In order to solve the above problems, the present invention provides a ladle lifting structure, which can solve the problem of difficulty in lifting the ladle caused by the difficulty in observing the lifting point of the ladle trunnion when the ladle is located in the VOD furnace or pit in the past. [...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D41/00

Inventor 张飞王凤良

Owner WUXI JULI HEAVY IND OFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com