Inverse proportion pressure reducing valve

A pressure reducing valve and inverse proportional technology, applied in the field of hydraulic control, can solve the problems of complex structure, insufficient pressure reducing range of the pressure reducing valve, poor linearity, etc., and achieve the effects of simple processing technology, simple installation and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

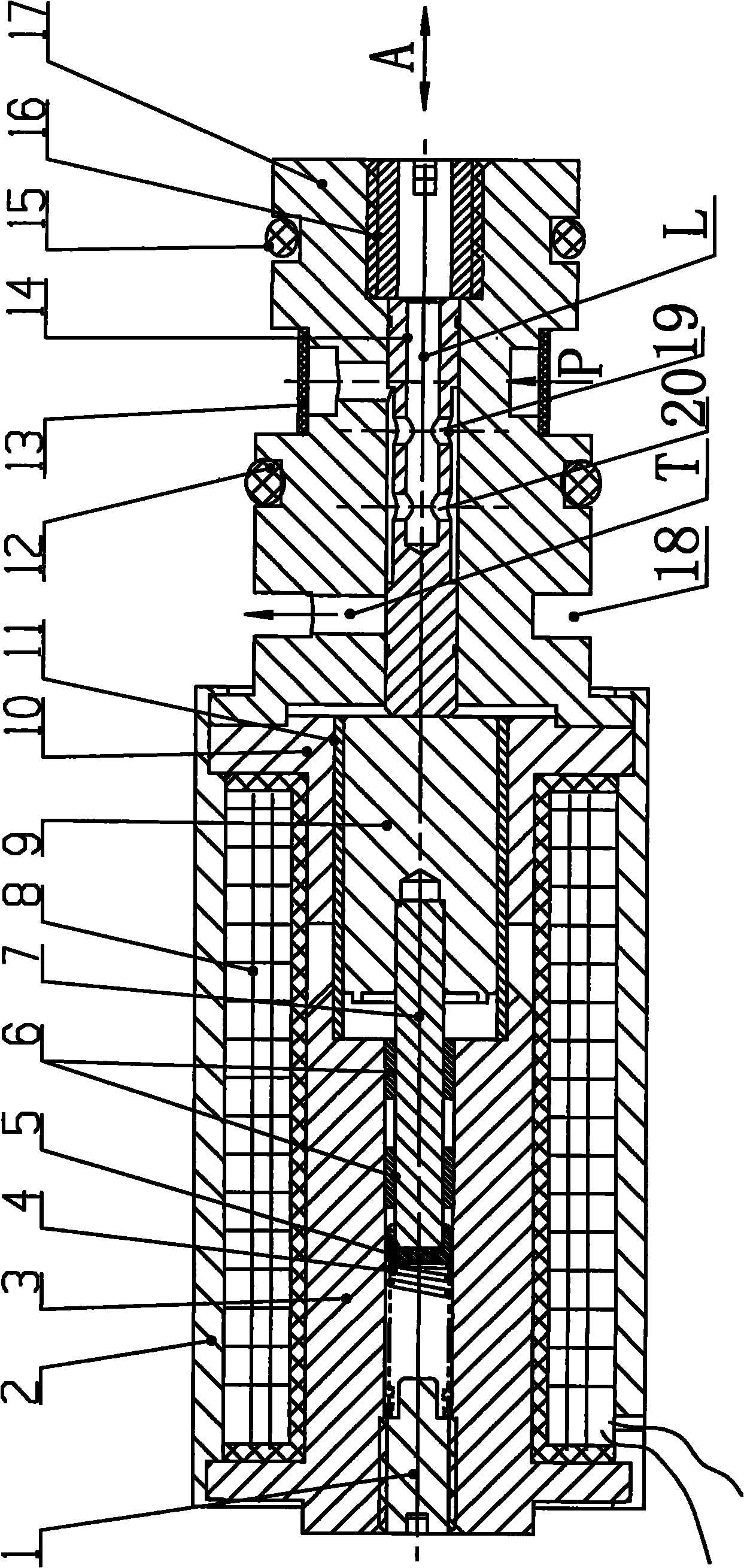

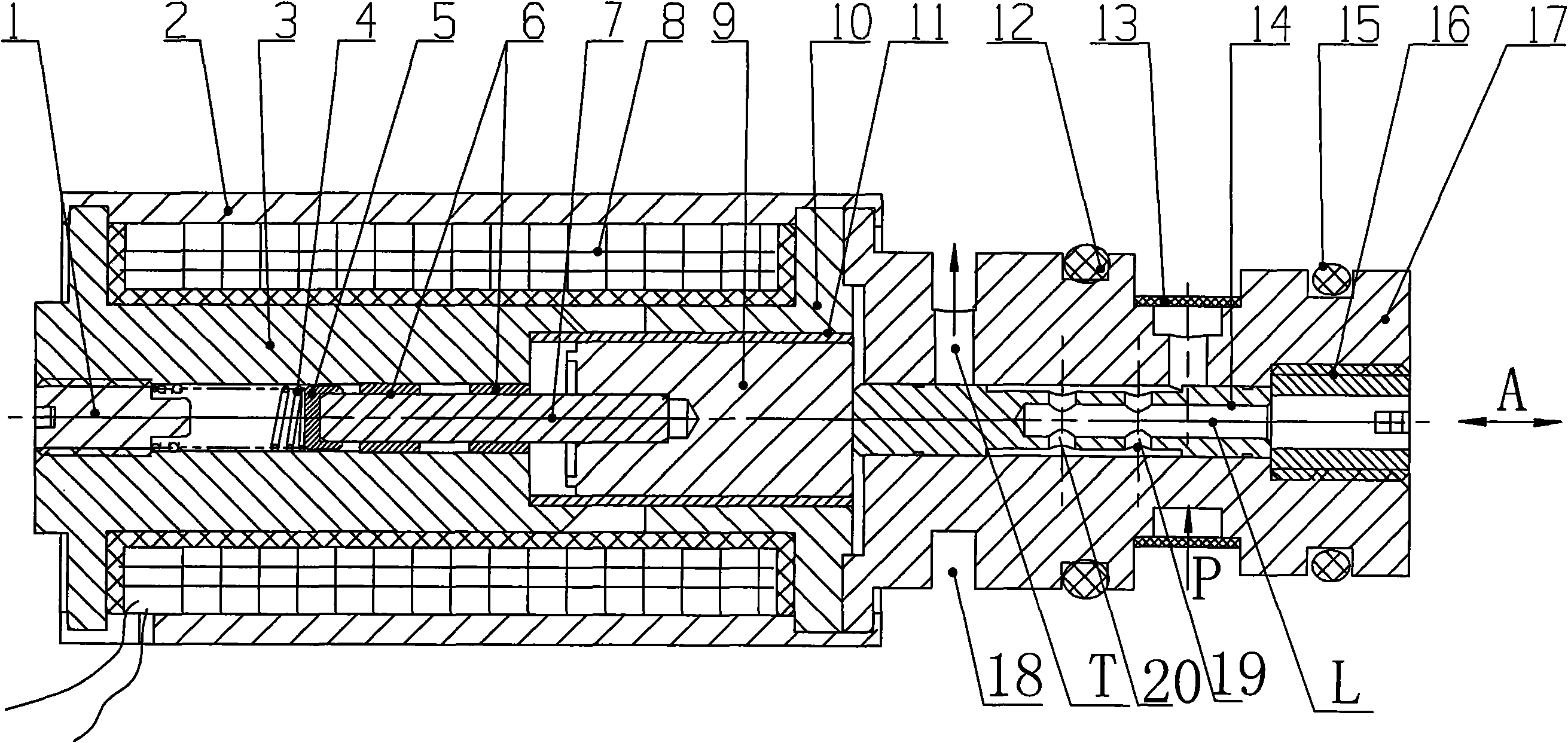

[0025] Such as figure 1 Shown is a structural diagram of the inverse proportional pressure reducing valve of the present invention, including an electromagnet assembly and a control valve assembly. The electromagnet assembly includes a yoke 2, an electromagnetic coil 8 embedded in the yoke 2, and a static iron set in the electromagnetic coil 8. 3 and the pressure plate 10, the spring assembly and the push rod 7 arranged in the static iron 3, the guide sleeve 11 and the armature 9 arranged in the pressure plate 10; the armature 9 can move axially along the guide sleeve 11 under the action of the electromagnetic coil 8 The spring assembly includes an adjustment screw 1 and a spring 4, the adjustment screw 1, spring 4, spring pad 5, ejector rod 7, and armature 9 are arranged in sequence along the axis from left to right; wherein a bearing 6 is arranged between the ejector rod and the static iron, One end 7 of the push rod is fixedly connected with the armature 9, and the armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com