Internal combustion engine and variable inclined-shaft vortex adjusting mechanism

A technology of regulating mechanism and internal combustion engine, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problem of inability to adjust the intensity and composition of oblique axis eddy current on demand, complex structure, inability to adjust the intensity and form of gas in the cylinder, etc. problem, to achieve the effect of low cost of modification, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

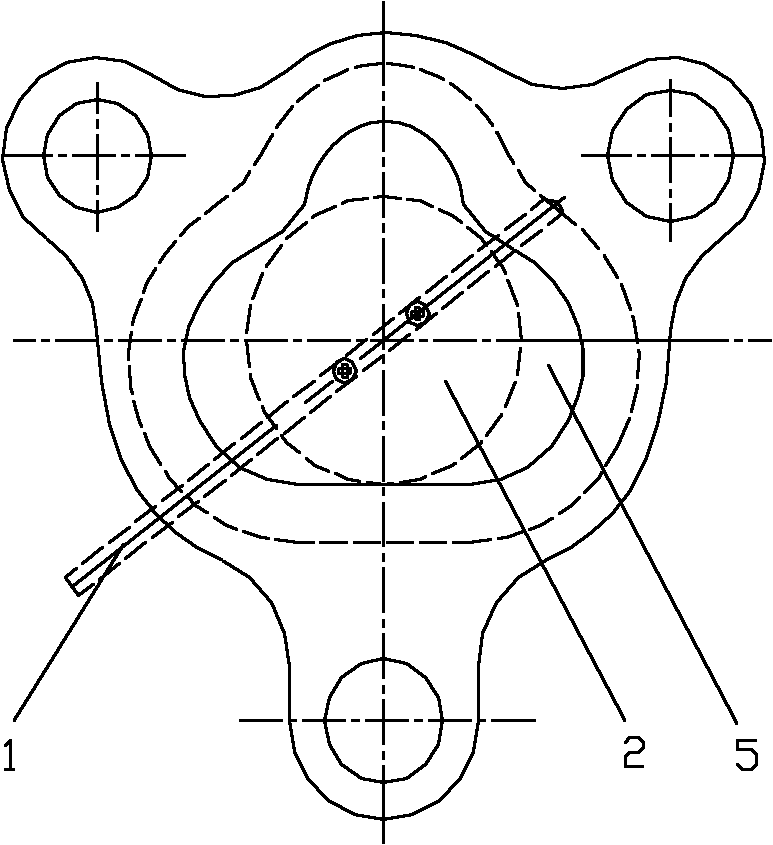

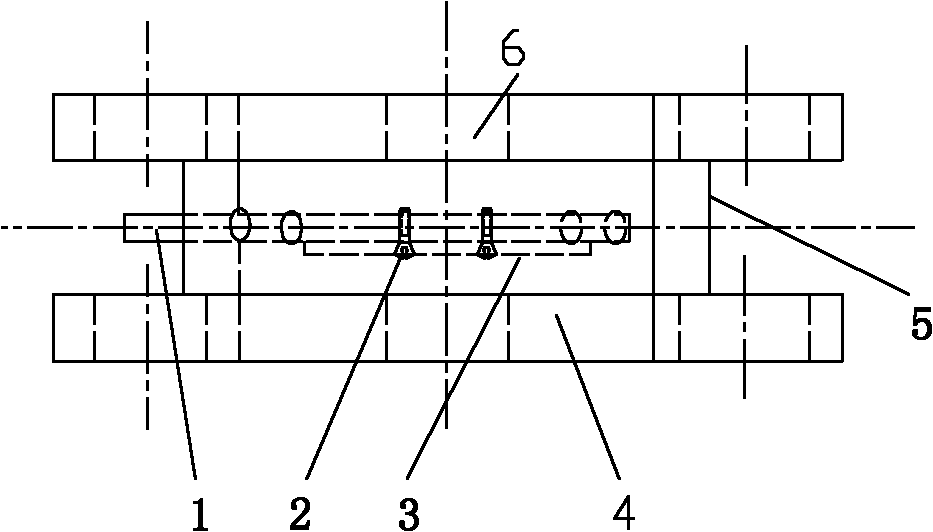

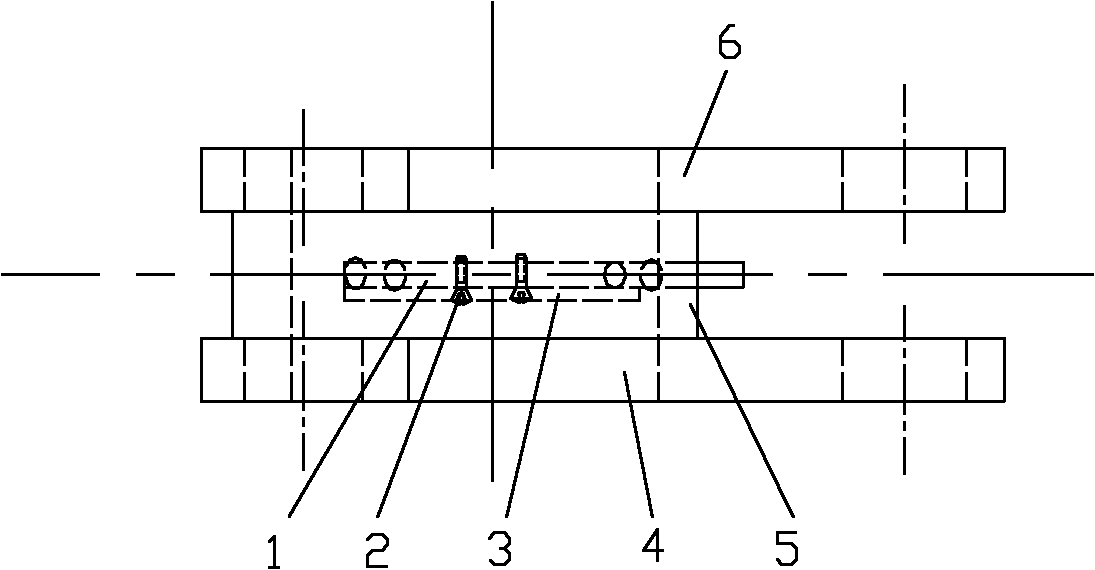

[0034] See attached figure 1 , 2 And 3, the variable oblique axis vortex adjustment mechanism of the present invention is located in the transition pipeline between the intake manifold of the internal combustion engine and the cylinder head inlet, the transition pipeline encloses the transition air passage 5, and the transition pipeline is provided with an oblique axis The swirl control valve plate 3 and its rotating shaft are the inclined-axis vortex control valve shaft 1. The inclined-axis vortex control valve plate 3 is fixed on the inclined-axis vortex control valve shaft 1 through the connecting screw 2. One end of the transition pipeline is connected to the intake manifold. The other end of the connected flange 6 is the flange 4 connected with the cylinder head.

[0035] In the figure, it can be seen that the oblique-axis swirl control valve shaft 1 and the crankshaft axis of the internal combustion engine ( figure 1 There is an inclination angle of 45° between the hor...

Embodiment 2

[0037] This embodiment is a CA4GB four-valve gasoline engine with one-piece gas passage, and the variable oblique-axis swirl adjustment mechanism in Embodiment 1 is provided between the intake manifold and the cylinder head intake passage.

[0038] The variable slant-axis vortex regulating mechanism in Embodiment 1 is used in this engine, and needs to be carried out according to the following steps:

[0039] 1) Design the experimental device comprising the mechanism in Example 1. In the experimental device, the rotation axis of the valve plate must be able to change continuously along the circumference of the transition pipeline.

[0040] 2) On the steady-flow airway test bench, install the experimental device on the engine cylinder head to conduct the airway experiment separately. The α suitable for this engine was found through the steady flow airway experiment v-axis is 60°, so that the adjustment range of the oblique-axis eddy current ratio of the variable inclined-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com