Reel flat pressing full-automatic die cutting machine

A flattening, fully automatic technology, applied in the field of roll flattening automatic die-cutting machines, can solve the problems of easy jamming, long feeding time, manual tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

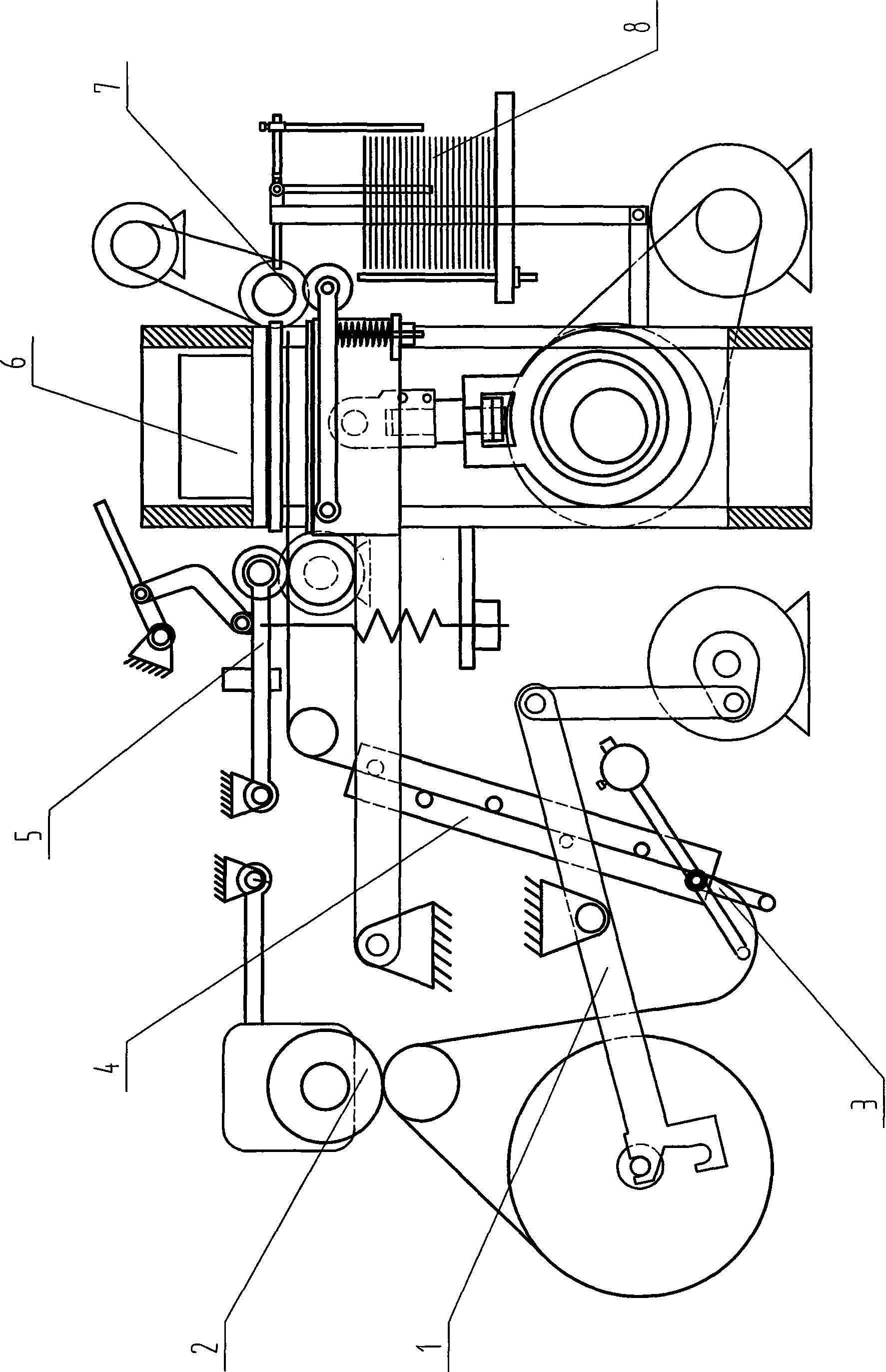

[0015] Roll material flat pressing flat automatic die-cutting machine of the present invention is made up of eight mechanism parts (as figure 1 ), in the figure:

[0016] 1--lifting mechanism 2--unwinding mechanism 3--guiding mechanism 4--recurve mechanism 5--feeding mechanism 6--die-cutting mechanism 7--cutting mechanism 8--collecting mechanism

[0017] The specific structure and working principle of each institution are as follows

[0018] (For the convenience of expression, the marks of each part in the following text are combined by the figure number and the part number to avoid repetition of figure numbers. For example: lift lever (2.3)-----expressed as figure 2 No. 3 in the name is the lift lever)

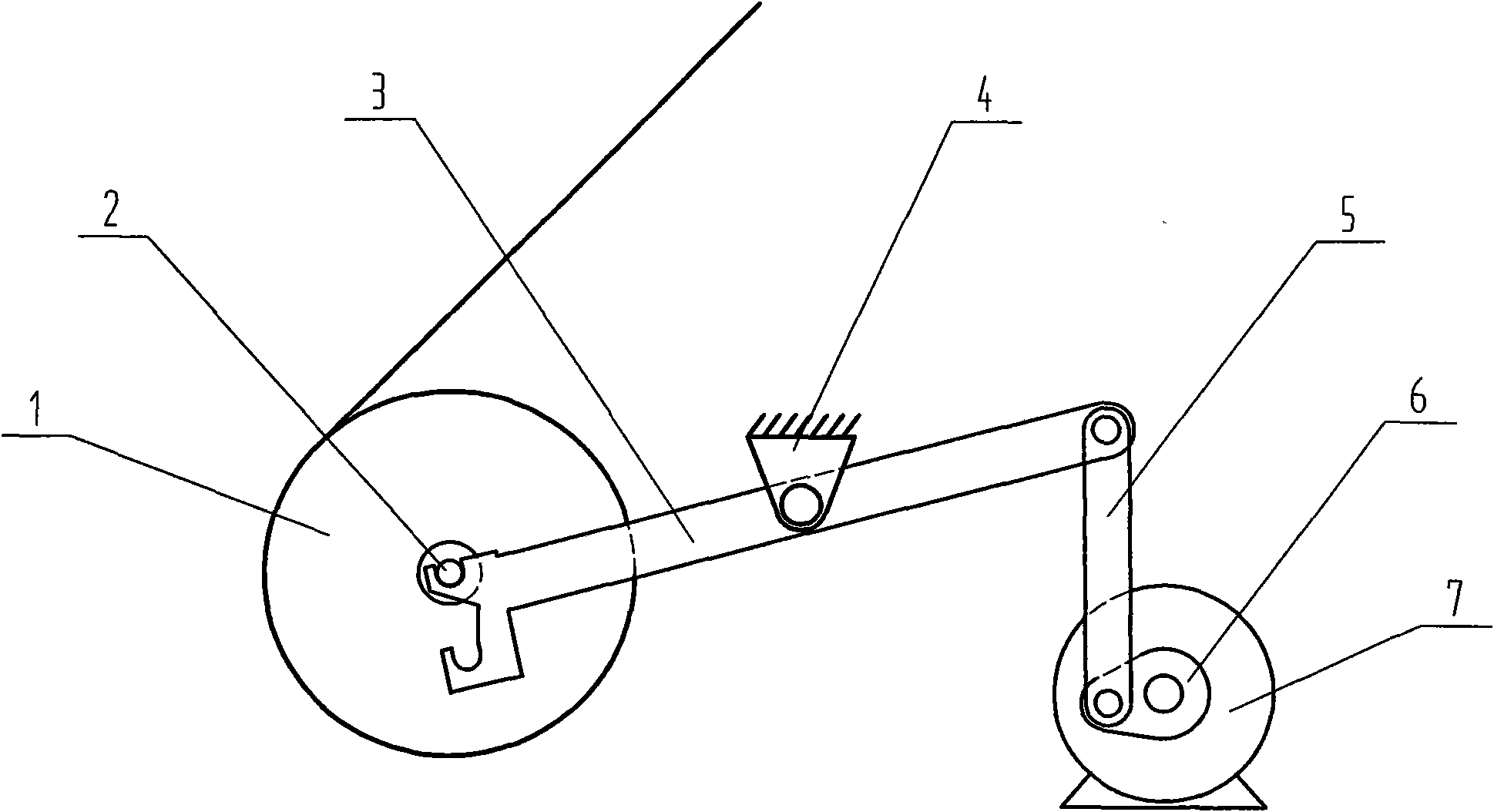

[0019] Lifting mechanism

[0020] Such as figure 2 After the reduction motor (2.7) is turned on, the two lifting levers (2.3) swing around the support (2.4) through the eccentric block (2.6) and the connecting rod (2.5) to lift the reel off the ground. The lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com