Welding fixture platform

A technology of welding fixtures and welding tools, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding site, high cost of fixtures, and low utilization rate, so as to reduce costs and increase utilization Efficiency, the effect of avoiding toxic and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and preferred specific embodiment, structure of the present invention is described further:

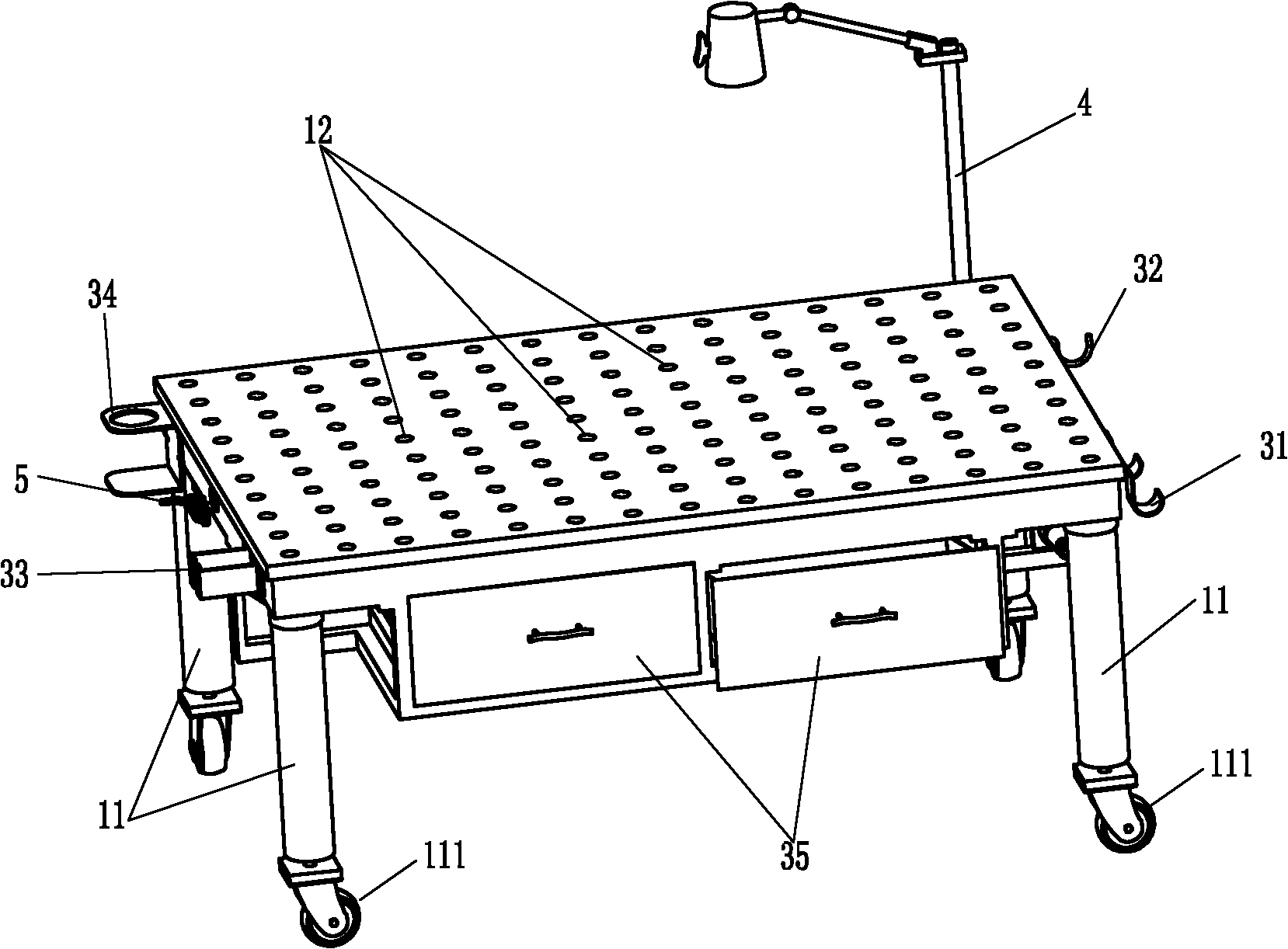

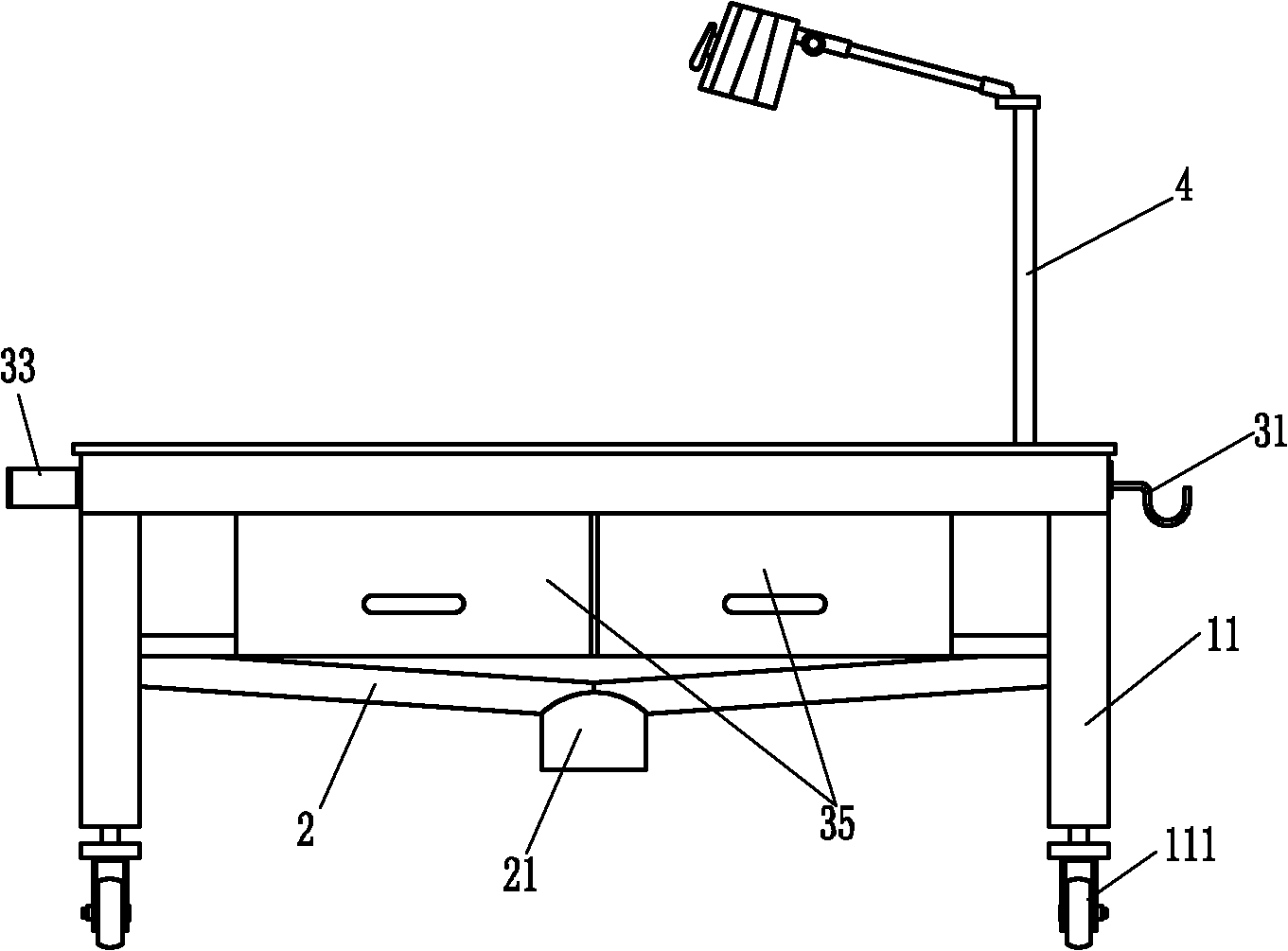

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in , the present invention mainly includes a table top 1 with four supporting legs 11, and the bottom of each supporting leg 11 is provided with universal wheels 111 for easy movement. The table top 1 is a three-dimensional flexible fixture plate structure, and there are several table top through holes 12 arrayed on it. The table top through holes 12 mainly have three purposes: one is for the welding slag generated during the welding process to fall into; the other is for the welding process. The poisonous and harmful gas and dust can enter; the third is for the positioning of the welding fixture. The welding fixture used to clamp the welding parts can be made into the form of a unit module. When fixing the welding parts, the unit modules are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com