Multi-functional automatic universal tank-washing device

A can washer and multi-functional technology, applied in the field of internal cleaning automatic universal can washer, can solve the problems of multiple movements of the washed vehicle, affecting the washing effect and efficiency, and workers suffering from various occupational diseases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

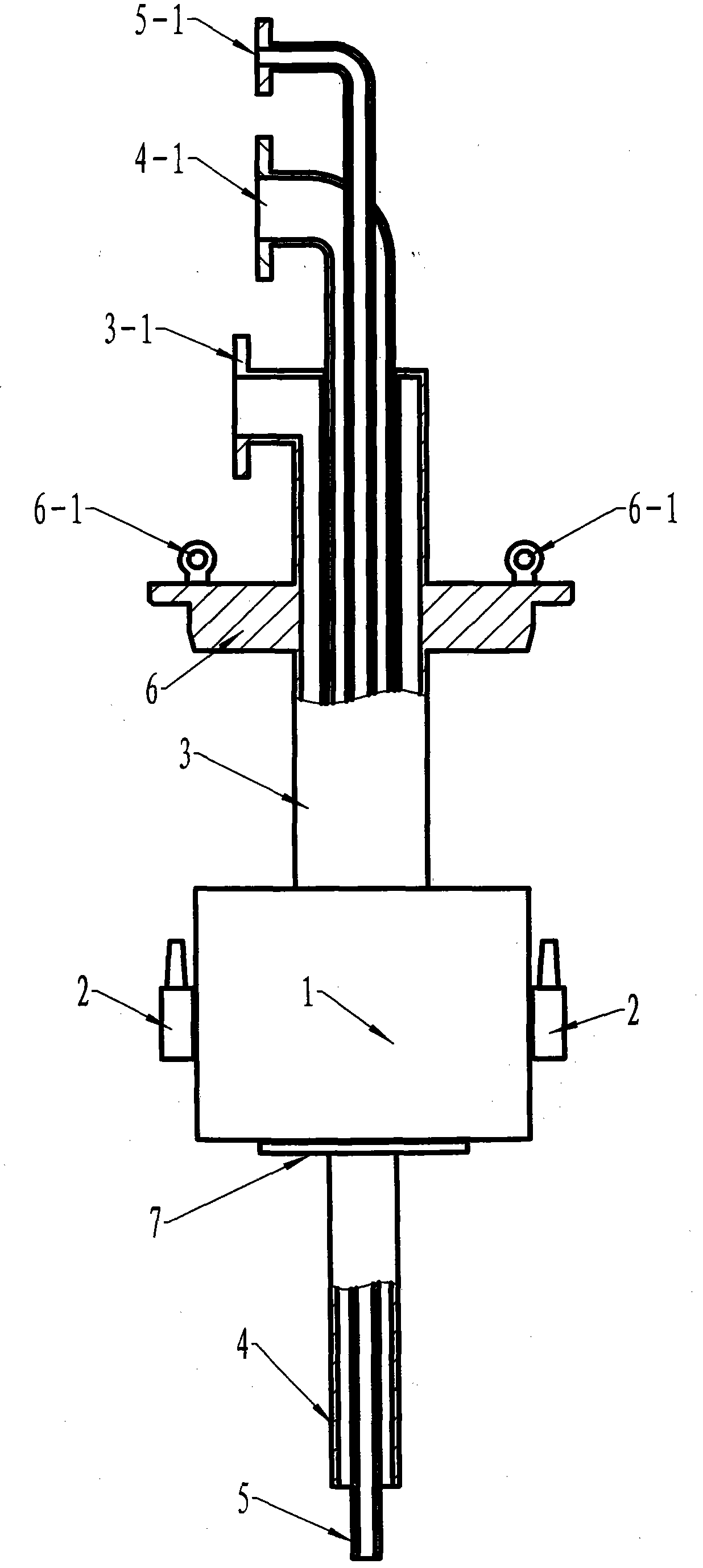

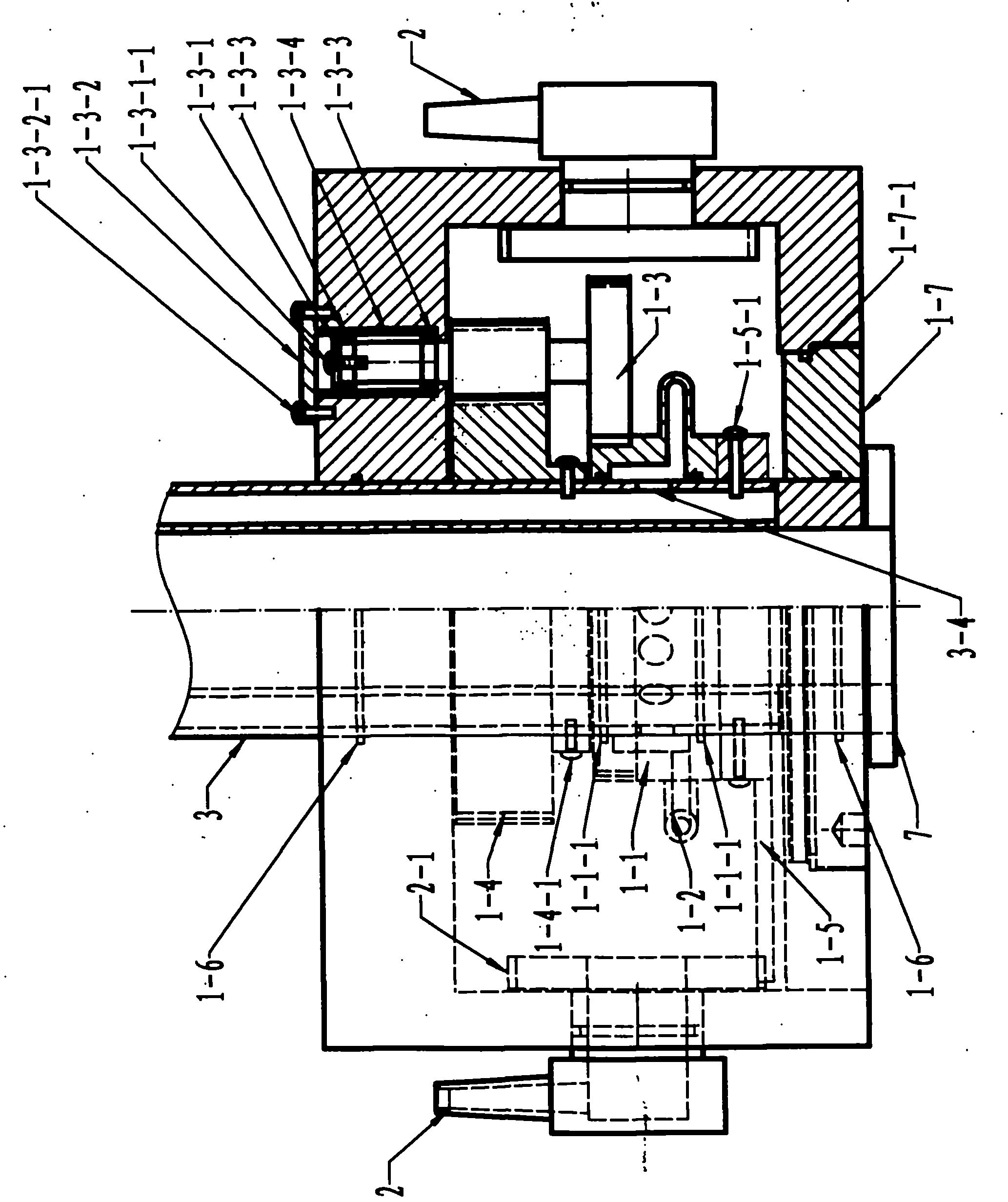

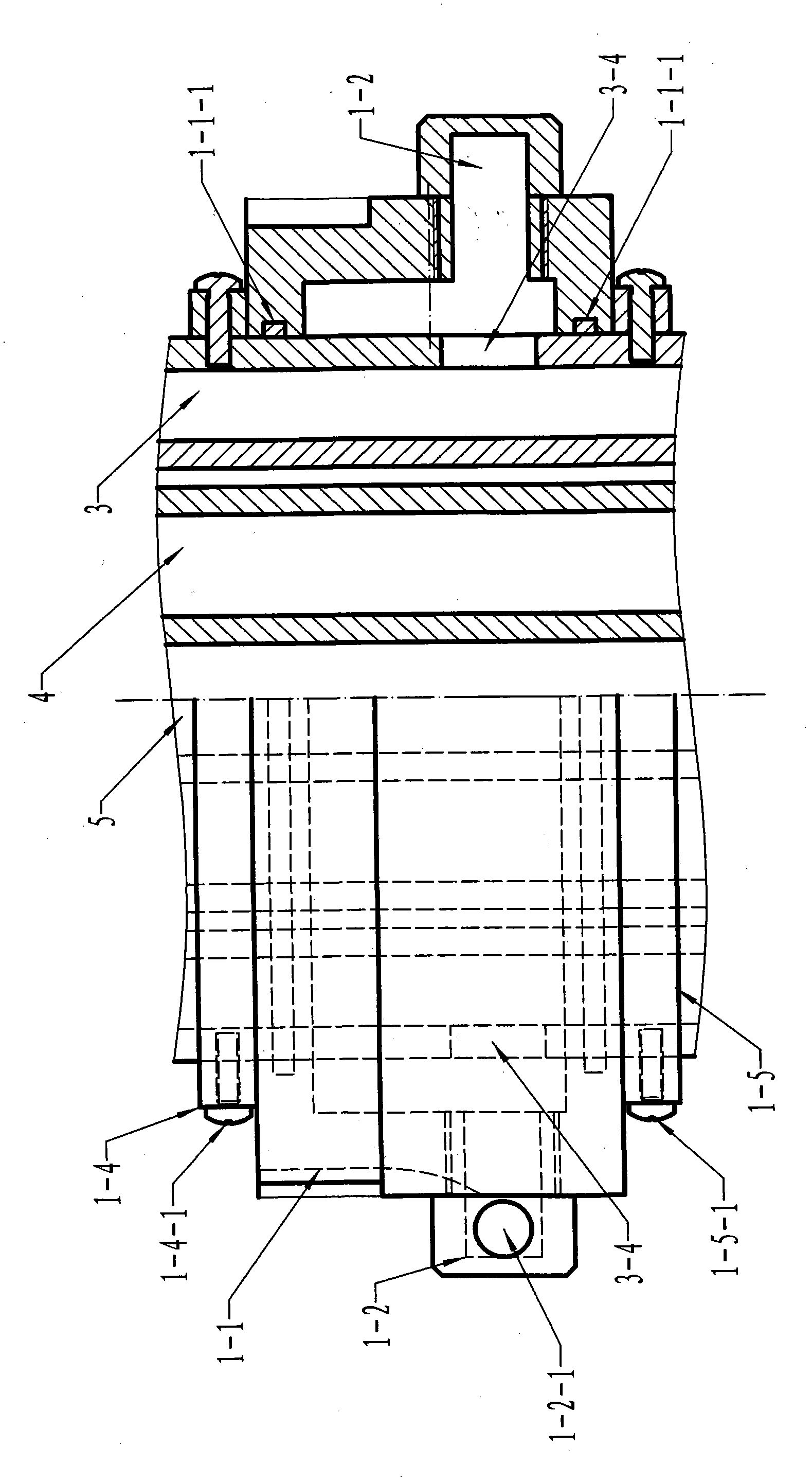

[0030] See figure 1 The overall structure description of the multifunctional automatic universal tank washer shown. When in use, pass the multi-functional automatic universal tank washer through the rigging of the lifting equipment, and get stuck in the hole of the hoisting ring (6-1), and put it into the well of the person who washes the tank, and the manhole on the device The well cover fixed seat (6) is automatically fixed on the manhole well on the top of the tank car being washed by its own weight.

[0031] After the external high-pressure water pump pressurizes the water, it connects with the water inlet pipe connector (3-1) through the connection head on the water delivery pipe, and the high-pressure water enters the rotating housing (1) from the water inlet pipe (3) 2) The water outlet on the top sprays out around the inner wall of the flushing tank. While flushing, the external self-priming pump is connected to the water suction pipe connection head (4-1) through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com