Zinc trifluoromethanesulfonate-loaded spherical mesoporous material, and preparation method and application thereof

A technology of zinc trifluoromethanesulfonate and mesoporous materials, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of low chemical reaction activity and limited practical application Value and other issues, to achieve the effect of high product purity, less side reactions, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

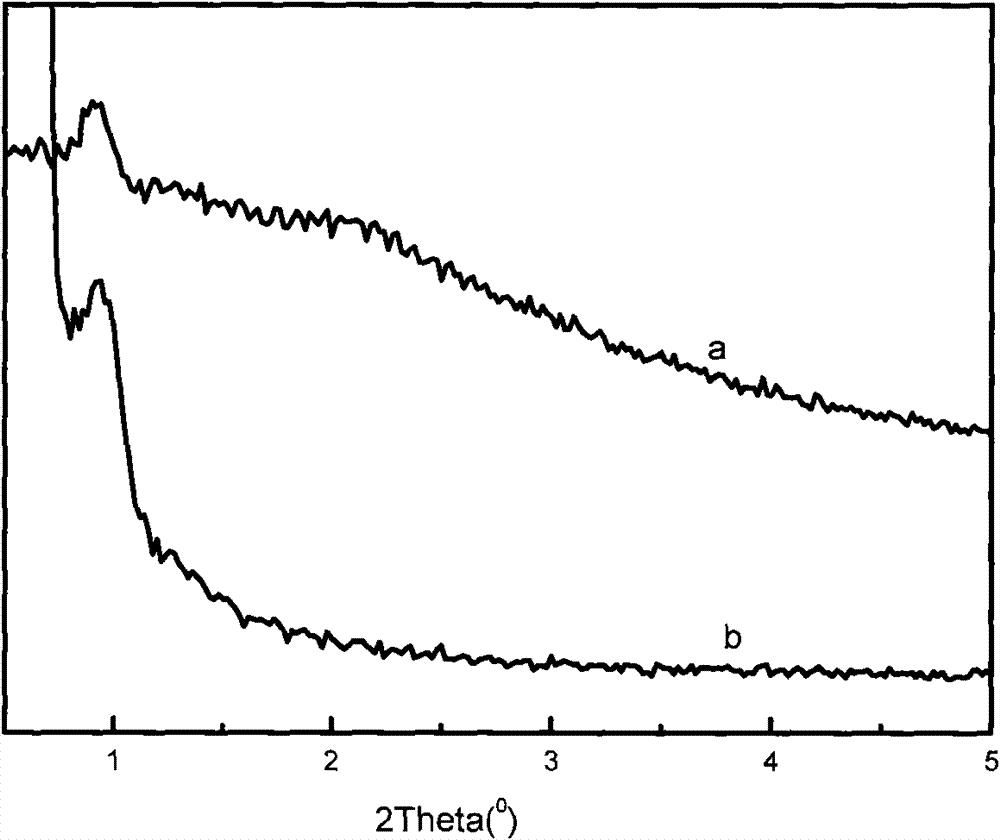

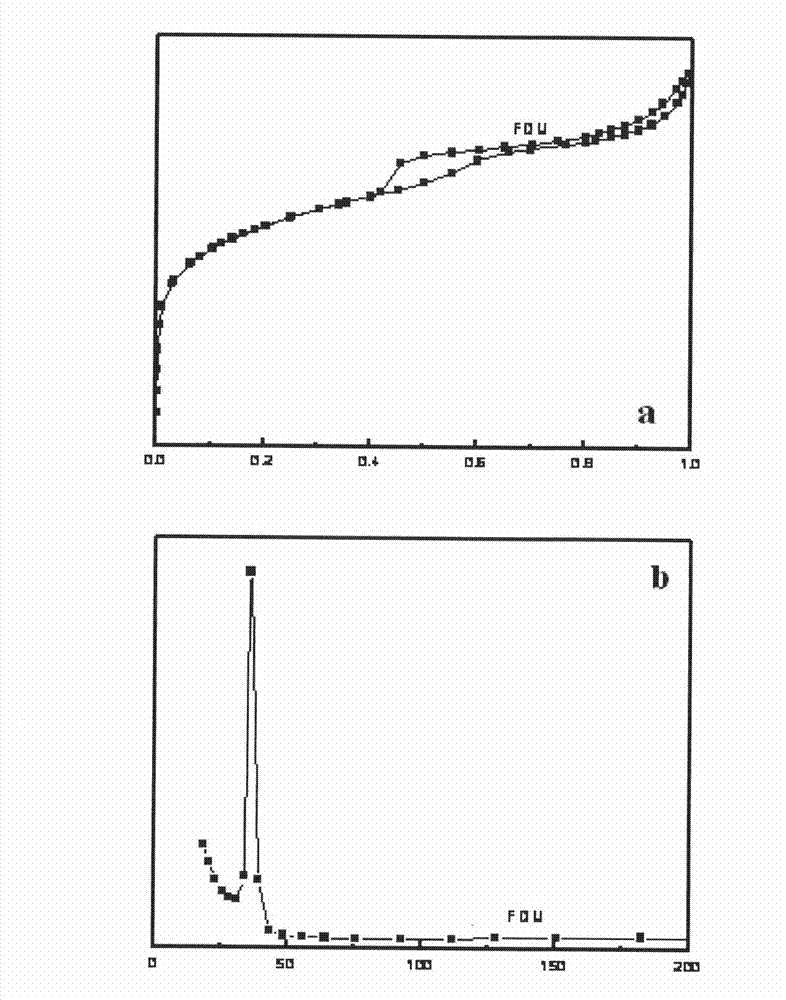

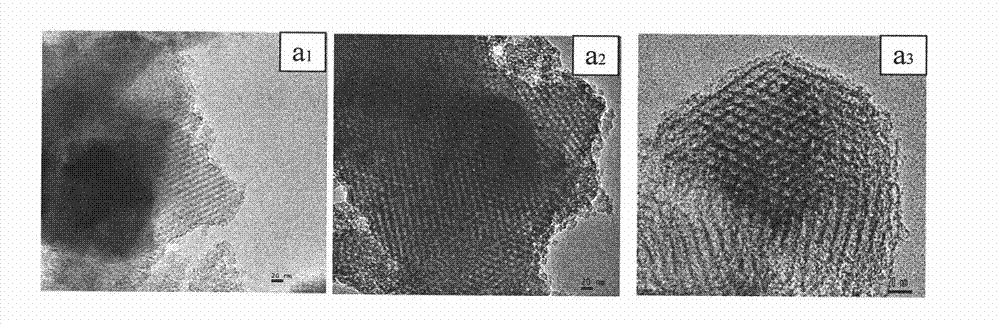

[0031] Example 1 Preparation of Spherical Mesoporous Materials Loaded with Zinc Trifluoromethanesulfonate

[0032] (1) 2.0 grams of F108 (Fuka company trade name Substance F108) with 5.24 g K 2 SO 4 Add to 60 grams of 2N hydrochloric acid solution, stir at 38°C until F108 is completely dissolved;

[0033] (2) Add 4.2 grams of ethyl orthosilicate to the above solution, stir at 38°C for 15 minutes, and then stand at 38°C for 24 hours;

[0034] (3) Transfer the obtained solution to a polytetrafluoroethylene-lined reaction kettle, and crystallize at 100° C. for 24 hours;

[0035] (4) adding 100 grams of deionized water to dilute, filter, wash and dry to obtain the former powder of spherical mesoporous material;

[0036] (5) Washing the raw powder mesoporous material with ethanol under reflux conditions for 24 hours, removing the template agent, and obtaining spherical mesoporous materials;

[0037] (6) 1g of spherical mesoporous material was vacuum-dried at 150°C for 6 hours...

Embodiment 2

[0040] Embodiment 2 prepares cyclohexanone-1,2-propanediol ketal

[0041] Weigh 0.5 g of spherical mesoporous material FDU-Zn(OTf) loaded with zinc trifluoromethanesulfonate 2 , then weigh 10 grams of cyclohexanone and 12 grams of 1,2-propanediol and put them into a 100ml three-neck flask together, add a condenser, stir for 60 minutes under the condition of heating and reflux, and after cooling to room temperature, centrifuge and use Gas chromatographic analysis of the product components in the liquid phase of the reaction showed that cyclohexanone was 5.3%, and cyclohexanone-1,2-propanediol ketal was 69.3%. Solid catalyst mesoporous material FDU-Zn(OTf) after centrifugation 2 Vacuum-dried at 150°C for 6 hours, cooled to room temperature, and recovered for reuse.

Embodiment 3

[0042] Embodiment 3 prepares cyclohexanone-1,2-propanediol ketal with the catalyst that reclaims

[0043] The 0.5 gram mesoporous material FDU-Zn(OTf) that embodiment 2 recycles 2 , put 10 grams of cyclohexanone and 12 grams of 1,2-propanediol into a 100ml three-neck flask, add a condenser, stir for 60 minutes under heating and reflux conditions, cool to room temperature, centrifuge, and use gas chromatography Analysis of the liquid components of the reaction product revealed that cyclohexanone was 4.0%, and cyclohexanone-1,2-propanediol ketal was 72.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com