Experiment device for researching jet atomizing characteristic of jet nozzle

A technology of atomization characteristics and experimental device, applied in the field of experimental device, can solve the problems of low temperature and pressure, waste of research on atomization characteristics of nozzle injection, inconvenience, etc., and achieve the effects of simple operation, flexible and diverse testing, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

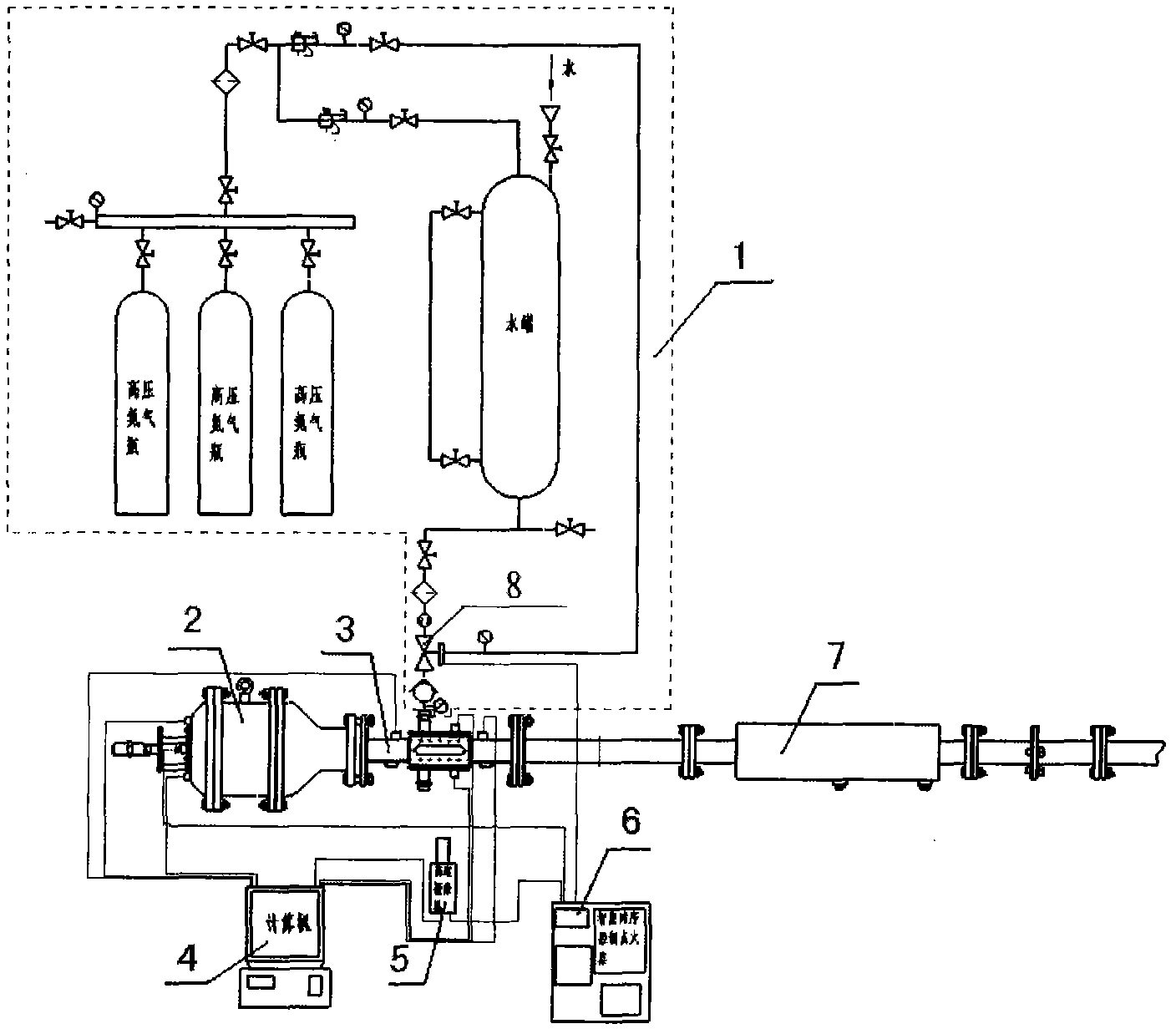

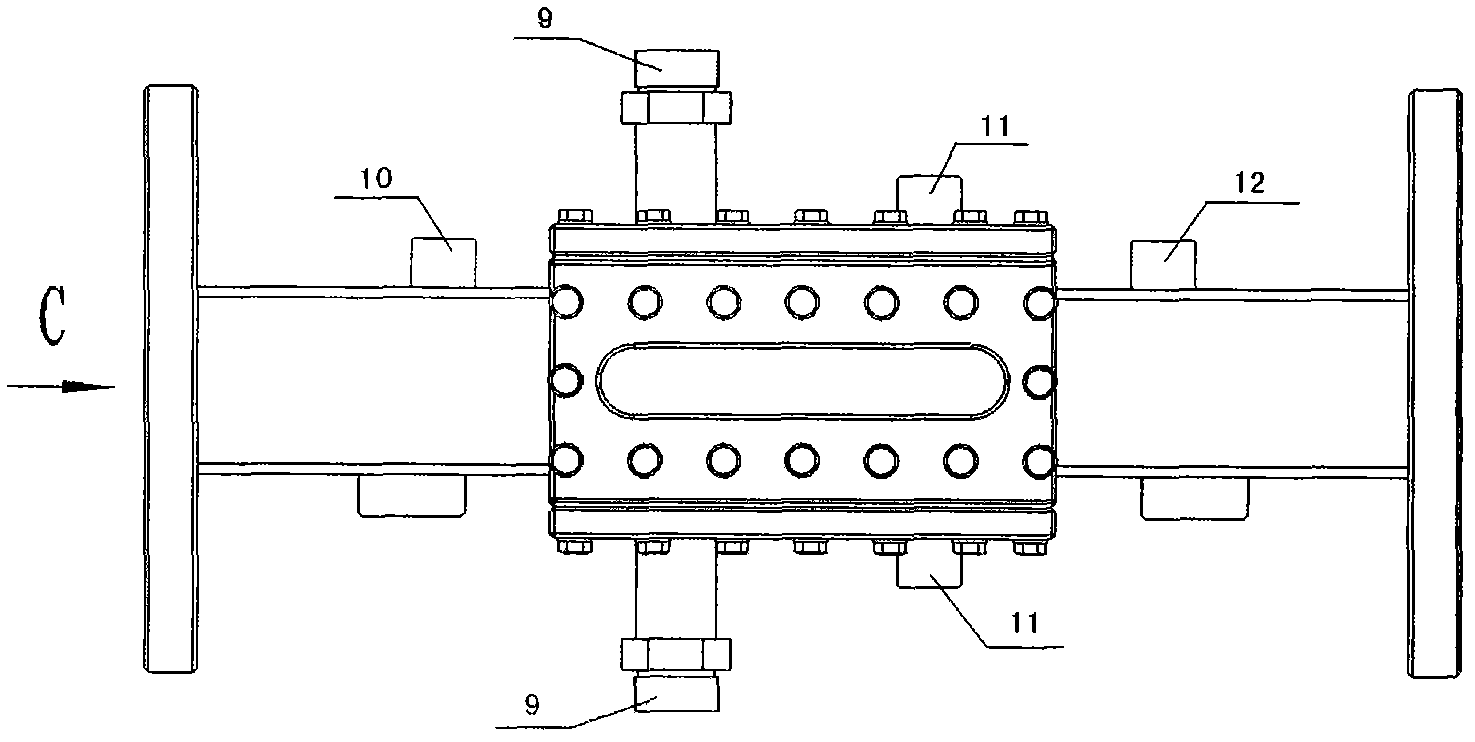

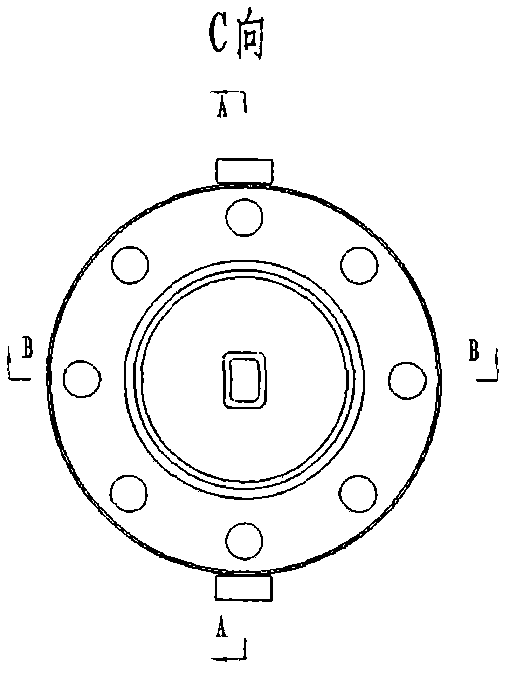

[0027] Refer to attached figure 1 , An experimental device for studying nozzle injection atomization characteristics established in this embodiment includes a water supply system 1 , a gas generator 2 , an experimental test section 3 , a data acquisition system 4 , a high-speed camera system 5 and a timing control igniter 6 . Water supply system 1 is an extrusion water supply system, which uses high-pressure nitrogen as the extrusion source. The extrusion pressure of the extrusion gas is obtained by adding the theoretical gas pressure in the experimental test section and the extrusion pressure during cold adjustment. The extrusion pressure is expressed as In the formula is the mass flow rate of water; ρ is the density of water; n is the number of nozzles; C d is the nozzle flow coefficient; r is the radius of the nozzle orifice, and the theoretical gas pressure in the experimental test section 3 is based on the working pressure and flow rate of the gas generator 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com