Micrometer for measuring over-ball distance between external gear and external spline

A micrometer and external spline technology, applied in the field of length measuring instruments, can solve the problems of influence on the accuracy of measurement results, poor measurement efficiency, unsuitable for self-inspection by front-line workers, etc., and achieves low measurement skills requirements, low manufacturing costs, and installation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing.

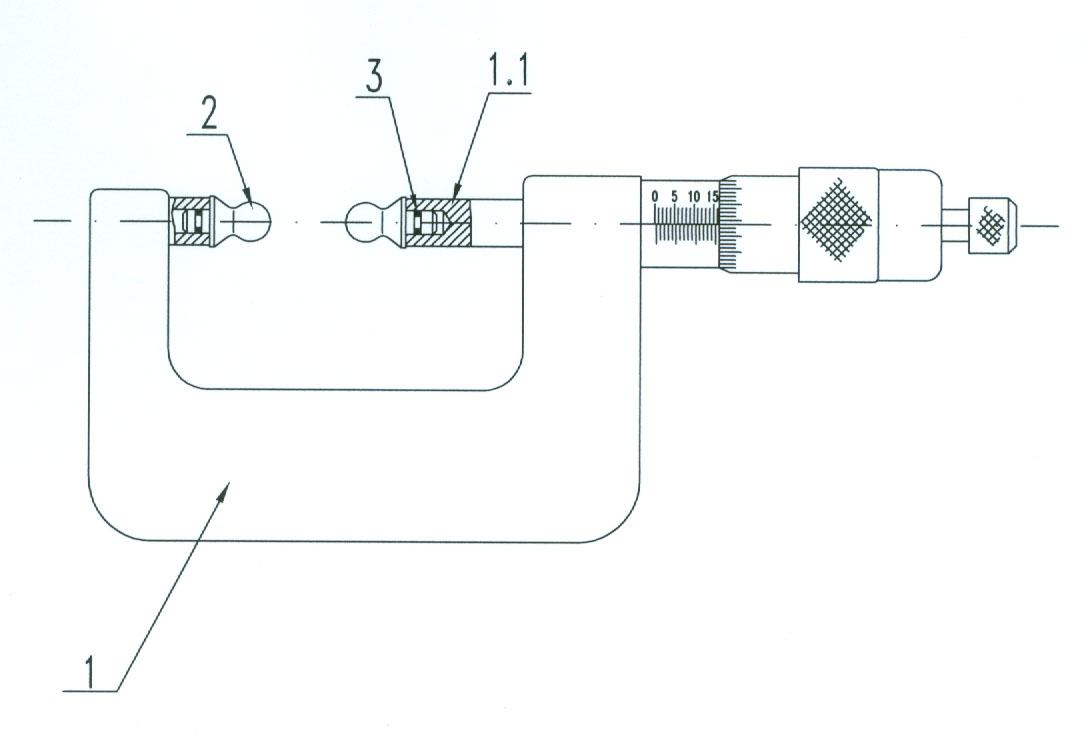

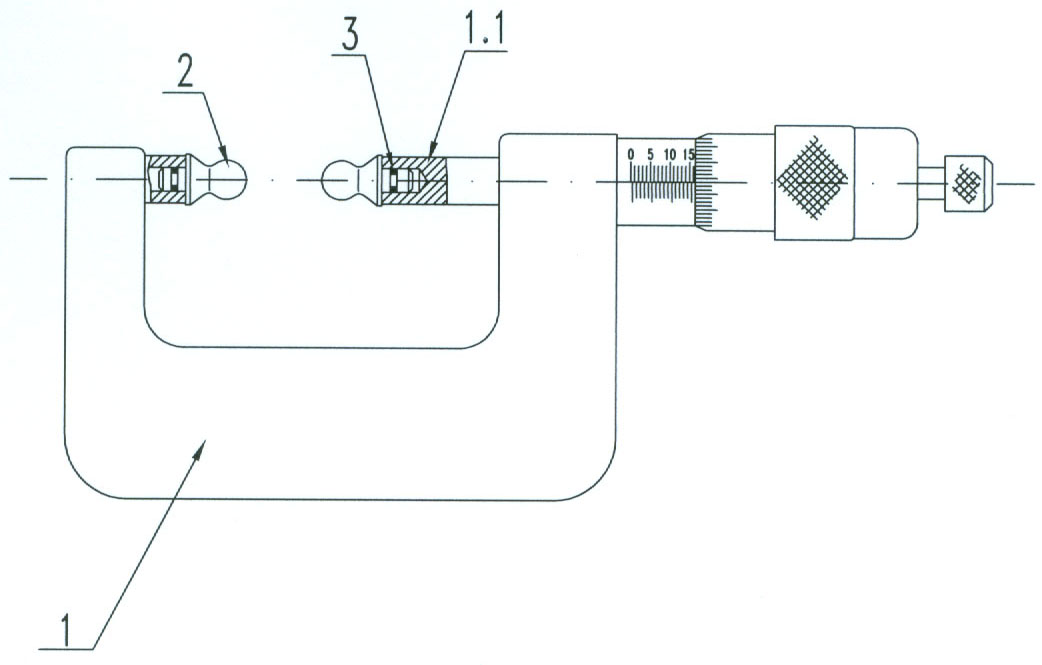

[0013] The cross-ball micrometer for measuring external gears and external splines shown in the accompanying drawing is composed of a micrometer 1, a measuring head 2 and a ring ring 3. The measuring head 2 is composed of a spherical measuring head, an intermediate transition shaft and a pin shaft. The pin shaft section is inserted into the small hole of the anvil 1.1 at both ends of the micrometer 1. The spherical measuring head directly contacts the workpiece to be measured. The spherical measuring head is Φ2mm~ For a sphere of Φ50mm, the pin shaft section matched with the measuring anvil 1.1 is a cylinder, and the middle section of the cylinder is provided with a concave ring groove for installing a snap spring 3 . In the present invention, the measuring heads 2 are used in pairs, the diameters and tolerance zones of the spherical measuring heads of the two measuring heads are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com