Integrated hot end phase adjusting structure of inertance-tube type pulse tube cooler and manufacturing method of phase adjusting structure

A technique for pulse tube refrigerators and manufacturing methods, applied in refrigerators, gas cycle refrigerators, manufacturing tools, etc., can solve problems such as poor anti-vibration, impact resistance, increased airflow disturbance, difficulty, etc., to ensure integrity and Stability, easy disassembly and assembly, strong impact ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

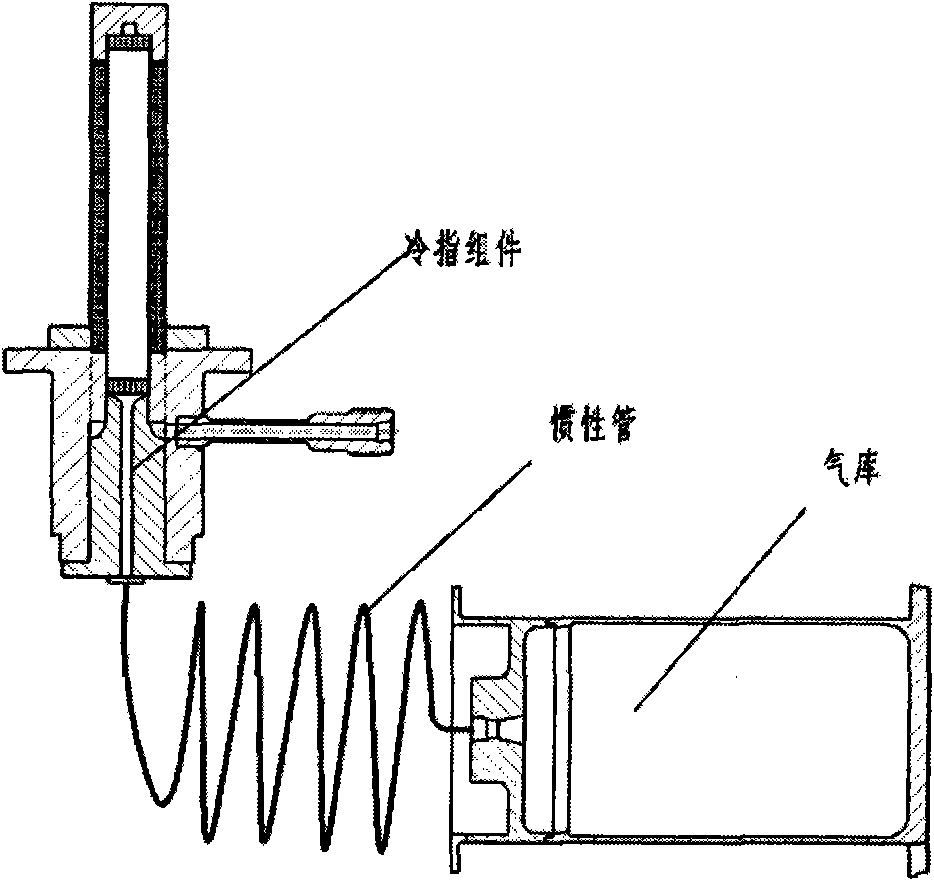

[0041] Figure 8 shows the communication of the gas working medium between the cold finger 22 of the pulse tube and the invented integrated hot-end phasing mechanism. The end of the inertial tube 26 with a small inner diameter and the gas outlet end of the hot end plug 25 of the pulse tube are sealed and welded using clean brazing technology to realize the communication of the gas working medium between the cold finger 22 of the pulse tube and the inertial tube 26 with a small inner diameter; the large inner diameter The end of the inertia tube 27 is sealed and welded with the inner gas storage joint 3 to realize the communication of the gas working medium between the inner gas storage 28 and the inertia tube 27 with a large inner diameter.

[0042] The small inner diameter inertia tube 26 and the large inner diameter inertia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com